The optimal configuration and size of the ring for the well

Many people think that the size of the well rings are always the same, in fact this is far from the case. There is a huge number of varieties of products that differ not only in size, but also in configuration features, production technology, materials used and the purpose of the finished structure.

The main characteristics of the rings and their impact on performance properties

The products of this group are usually made in industrial plants using modern equipment that provides the highest indicators of quality and reliability. All products go through several stages of processing, giving concrete optimum operational properties..

According to building codes, the safety of operation and durability of concrete rings must be guaranteed by compliance with GOST 8020-90. Therefore, before buying it is better to ascertain from the seller or manufacturer about the availability of documents confirming the quality of the product. (See also the article Features of water supply from a well.)

Do not neglect this point, as often the rings are made in an artisanal way, which is fraught with the following disadvantages:

- Concrete of the highest quality can only be obtained by automating the dosing and mixing process. With the manual method, proportions are not always respected, and the mixing of the solution is not done so carefully.

- The reinforcement of elements is made of materials of low quality and with violations of technology. As a result, resistance to deformation effects is much lower.

- Most often, in such handicrafts, the quality of the forms is not very high, and geometry may be disturbed, as a result of which the dimensions of the well ring may be incorrect.

Note! Rings produced in the factory are tamped on the vibration equipment, which ensures a high density of the structure, and drying is performed in special rooms with high-temperature treatment with water vapor. Naturally, the artisanal method of these operations does not imply.

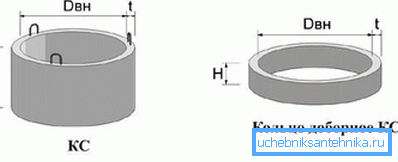

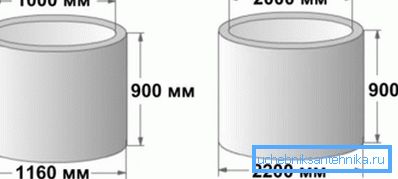

Diameter of the element

Immediately, we note that there are two of these values, and each one will tell you a lot about the design:

- The inner diameter is the size that is basic, it is reflected in the marking and shows the actual cavity, which is formed during the installation of the structure. The choice of a particular option primarily depends on the characteristics of the use of products, this aspect will be discussed below.

- The outer diameter indicates how large the shaft should be under the well. It is not indicated in the marking for the reason that, knowing the thickness of the wall, the value can be calculated by hand with a simple arithmetic operation.

What does this factor affect, and in which option is it better to stop the choice?

It's all quite simple:

- For sewers, it is better to choose elements of large diameter (most often the two-meter version is chosen). This contributes to good drainage of wastewater. In addition, the larger the well, the lower the moisture level in it will be.

- For gas and electrical lines, the diameter of the well is selected depending on the configuration and features of the system. The main factor here is the ease of installation work and the reliability of the protective structure.

- For water-bearing wells, a small diameter is chosen, since the water level in the wide shaft will be much lower than in the narrow one. At the same time, it is not necessary to choose too small a size, since the well needs periodic cleaning and maintenance, and it is very inconvenient to do this in a confined space.

Element height

The size of the ring for the well necessarily reflects the height indicator.

This value affects the following factors:

- The greater the height of the ring, the simpler the installation process and the higher the structural strength. This is due to the small number of compounds. But at the same time, it should be remembered that concrete is a rather heavy material, and with an increase in height, the weight of an element increases very significantly - it is impossible to carry out work without special equipment.

- For each type of work there is an optimal size of parts, which you will be prompted at the place of purchase of products. Most often this is the average option. Products of small height are used as additional elements if the full ring is not suitable.

Wall thickness

A very important parameter that ensures the reliability and durability of the item. The thicker the wall, the stronger the ring. In addition, thick walls make the well resistant to the effects of the quicksand of the well and moving soil layers.

You should not buy rings, the walls in which are thinner than 8 centimeters. This thickness is optimal in terms of price-quality. Sometimes you may need a large thickness, but, as a rule, eight centimeters are enough.

What else is worth considering

There is one more factor that should not be overlooked - the presence of special connecting grooves, or, as they are also called, locks well rings. Thanks to this system, the assembly design is much easier. In addition, the well is stronger and more resistant to the deforming effect of soil layers.

Unlike rings with even ends, the process of sealing seams is much simpler: it is enough to mix a special solution as recommended by the instructions, and to seal up the narrow gaps at the joints.

Tip! Rings with a quarter are much more convenient to use, and if you make a well yourself, it is better to choose this option.

Conclusion

Correctly find the required size of the rings is a snap. The main thing is to follow the advice given in this article and take into account the opinion of experts. The video in this article will explain in more detail some of the nuances.