The size of the rings for wells - much more than the height

Of course, you can equip a well in the country in various ways. But when industrial well-made reinforced concrete rings have become so easily accessible, it just suggests that they should be used. It remains only to find out what sizes of well rings are offered by manufacturers, and to coordinate their further actions with these parameters.

Details of the most important

Not only the production of the rings themselves, but also of the floor slabs is subject to the standards defined in GOST 8020-90. First of all, the brand of cement used for the production of these products is regulated - it is from M200 to M500 and no less.

A small introduction to the subject

In addition, the following conventions are defined, which are accepted for the presentation of a rather large manufactured item:

- KS - Wall - for narrow mouths and working chambers of wells;

- KO - Support;

- KVG - for Water and Gas - recommended for use as working chambers not only in water supply systems, but also in gas pipeline networks;

- KFK - for Fecal Chambers - these are directly for sewage;

- KLK - for the Storm Sewerage - drains also belong here.

- PD or PN - Bottom Plates ”- which is no longer relevant for water wells;

- PC or PP - Slabs - in addition to the entire range.

The standards also include the conventions defining the characteristics of each ring.

Thus, the designation KS-10-9 defines:

- the diameter of the proposed wall variant is 100 cm;

- height - 90 cm.

The spread of parameters is quite large:

- diameters - from 70 to 200 cm;

- height - from 10 to 90 cm;

- by weight, in this way - from 43 to 1470 kg, when either an ordinary mount is suitable for installation or a solid crane is required.

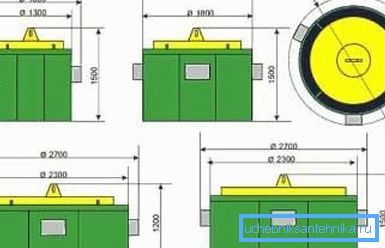

Helpful advice! If you want more comfort in the construction of the entire vertical structure and you are not satisfied with the weight of iron and concrete products, we advise you to pay attention to the plastic options of wells. In terms of their strength and reliability, they are in no way inferior to reinforced concrete, but they have an order of magnitude less weight and are significantly cheaper.

Details about the main thing

Among all the possible parts used in the construction of wells, rings are essential, so the conversation, first of all, about them.

Dimensions

We give the sizes, from easier products to more difficult:

- KS-7-1:

- height (mm) - 100;

- wall thickness (mm) - 80;

- inner diameter (mm) - 70;

- weight (kg) - 46;

- price (rub) - 339;

- KS-7-1.5: 150/80/700/68/379;

- KS-7-3: 350/80/700/140/589;

- KS-7-5: 500/80/700/230/897;

- KS-7-6: 600/100/700/250/910;

- KS-7-9: 900/80/700/410/1287;

- KS-7-10: 1000/80/700/457/1495;

- KS-10-5: 500/80/1000/320/1259;

- KS-10-6: 600/80/1000/340/1279;

- KS-10-9: 900/80/1000/640/1769;

- KS-12-10: 1000/80/1200/1050/2730;

- KS-15-6: 600/90/1500/900/2340;

- KS-15-9: 900/90/1500/1350/3059;

- KS-20-6: 600/100/2000/1550/3835;

- KS-20-9: 900/100/2000/2300/4745;

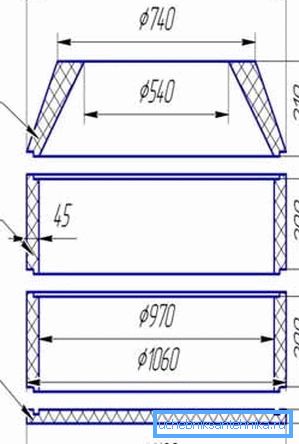

- Ko-6 7: 120/580/600/369.

Some notes

All given a jumble of numbers requires some explanation:

- Firstly, the price quoted is indicative and may vary by 20-30% in different regions.;

- Secondly, the maximum possible height of products is - 900 mm / 90 cm;

- Thirdly, the minimum height is 100 mm or only 10 cm, which is very convenient when building wells in suburban areas. - you can always pick up rings of different heights to fit them over the dug well; the main thing here is just not to be mistaken with the diameters, both external and internal.

- Fourthly, on the basis of the last remark, we conclude that when building water wells, rings with a thickness of 80 mm and an internal diameter of 700 mm would be most prevalent if it were not for a very small diameter., and so, you have to choose a diameter of 1200 or 1500, but at the same time adjust the height of the recess.

Helpful advice! When looking at price lists, pay attention not only to the diameter of the rings for the well, but also to prices. And, most importantly, specify whether the price includes VAT and delivery of the product to the installation site - for such weights it is essential. In the proposed table, both of these amounts are already included in the final price.

findings

The diameter of the well rings and their height - the first indicators for which you select these products. Be sure to determine the requirements for the future well before starting the excavation work in accordance with the size of the rings to be used.

In this regard, pay special attention to the depth of your aquifer and its thickness, aligning these data with the height chosen. Check out the additional video in this article, it will help you more accurately navigate the proposed figures.