The steel crane - simplicity and durability in one bottle

Steel taps with a locking part in the form of a steel ball are distinguished by increased durability and simplicity of construction. The ability to almost instantly shut off the flow of liquid or gas is highly valued not only in everyday life, but also in industry - such devices can be found both in a regular apartment and at a powerful chemical enterprise.

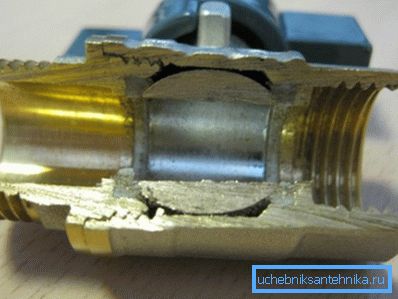

Briefly about the device and classification of ball valves

All ball steel valves have a similar design - the locking element is presented in the form of a metal ball with segments cut in parallel. In the center of the ball is a through hole, and adjustment of the flow of liquid or gas is carried out by simply turning the handle.

Note! A conventional ball valve has only 2 working positions - fully open or closed, this is how they differ from ordinary valves.

As for the classification, it all depends on the criterion underlying the division into groups.

So, according to the method of attachment, you can select such options as:

- clutch - it is installed as an ordinary coupling for pipes (there is an internal thread on both sides, so that the pipes are simply screwed into the tap). Such compounds are particularly sensitive to the quality of the assembly and operating conditions; if it is subjected to vibrations and pressure drops, it is better to abandon the clutch model. Due to the fact that such a connection is detachable, such devices are especially popular when installing water and heat pipes;

- flange connection - discs with holes are welded from the ends, and the connection to the pipes is carried out with the help of bolts. A steel ball flange valve is somewhat larger and weighs more than a clutch one, but it can be used in quite harsh conditions, in industry, as a rule, they prefer such devices;

- welded joint - can be considered the rarest type, belongs to the class of one-piece. It can be used only in the case when its replacement in the future is definitely not needed. Of the strengths, one can only note that the resistance to mechanical stress, vibration, etc. - the correct welding strength is almost as good as the metal of the pipe. A steel ball valve for welding is usually installed in places where operating conditions will not lead to its rapid degradation, i.e., humidity is normal, and so on;

- Various combinations of the listed compounds are possible.. For example, the designation nut-nut says that there is a cap nut on both sides, which will allow to install it even in the conditions of a shortage of free space. Other combinations are also possible, such as choke-nut, etc.

You can divide the taps and on the principle of action:

- bushing taps provide a simple passage of a stream of liquid / gas without changing its direction and without mixing up another stream. Depending on the shape and size, full bore devices can be distinguished (the diameter of the hole is equal to the internal diameter of the pipe) and models in which the hole is smaller in size than the passage in the pipe;

- angular devices - provide rotation of the flow at an angle of 90 ?;

- three-way models - a steel three-way valve can work both as a mixer and as a flow divider (its design is discussed below).

The classification can be given by the type of handle. It can be noted that small-sized cranes are equipped with compact butterfly-shaped handles, this is due to the fact that to close it requires relatively little effort. But the larger devices are equipped with a conventional handle, this allows you to close the faucet with little effort.

Note! In industry, sometimes the installation of a large handle is impossible due to the lack of free space, in such cases an electric drive is used to regulate the operation of the crane. Of course, the price of such a device is not democratic.

Read more about the use and installation of steel ball valve

The principle of operation of the conventional throughput model was considered above, much more interest is caused by cranes with 3 or more pipes, that is, 3-way valves, etc. Such devices are more complicated, but they provide more opportunities compared to conventional cranes.

Three way valves

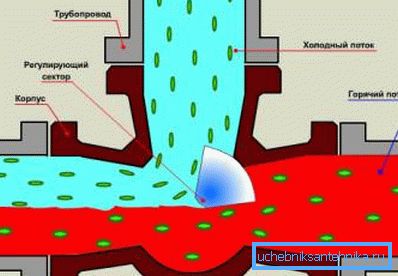

The maximum that a conventional through-valve can control the flow of a liquid / gas flow, 3-way, is able to separate or mix flows.

Actually, according to this criterion, their classification is performed:

- mixing tap - mixes 2 liquid flows. Such devices are used as ordinary mixers in apartments. Despite the more complex internal design, its installation remains simple and is done by hand;

- separators - in such devices the incoming fluid flow is divided by 2. It can also completely redirect the incoming flow to one of the connected systems. This makes it possible, for example, to completely separate the individual circuits in the heating system; this is useful when using low temperature and conventional heating in the house at the same time.

As for the control of the crane, the most often encountered models with manual adjustment. But if the budget is not a limiter, then it is quite possible to organize an automatic adjustment. All that is needed for this is to install on it a servo-driver associated with a thermostat located in the room.

Steel crane installation

Installation instructions are extremely simple and depend on the type of fastening (clutch, flange, etc.):

- when using a cap nut, it is sufficient to wind the FUM tape on the external thread on the valve itself, then put a gasket, a sealing ring and the nut on the pipe. After that, it will only screw the nut on the thread on the valve;

- in the case of flange fastening, the connection with the flange on the pipe is provided by high-strength bolts, which are tightened with a torque wrench. Between the flange on the crane and on the pipe, a sealing gasket is always located, if necessary, you can always tighten the bolts, the only thing you need to pay attention to is that all bolts must be tightened with the same force.

Summarizing

Steel ball valve due to its simplicity of design, reliability and durability has taken a worthy place not only in the arsenal of plumbers, but also in industry. A small improvement in its design (three-way models) allows to solve almost any problem of adjusting the flow of liquid or gas through a pipe.

It is also important that any person can cope with the installation of such a device. The video in this article shows an example of using a 3-way valve in the heating system.