Types of borehole pumps and their features

Construction of your own well begins with the right choice of a suitable pump. This element will perform the main function of supplying water to all points of consumption.

To date, many different modifications have been proposed that differ in their working principle, size, cost, and performance. In this article we will look at the most common options.

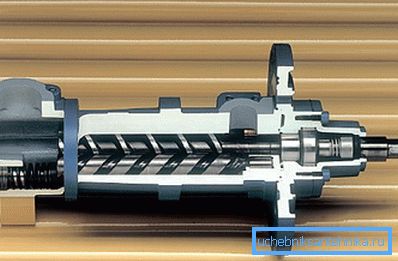

Screw

Screw borehole pumps are a construction of a rotor with the required number of turns and a stator with a female thread located around it. In this case, the number of turns of the stator is one more than that of the rotor. The inner element is made of high strength steel, and the outer of elastic material.

The principle of operation of such a unit is that water flows along the internal spiral of the stator due to the rotation of the rotor.

Dignity

The main advantage of such a device is one, but in some cases it is irreplaceable. This is the ability to pump liquid with a large amount of impurities.

Thus, it can be said that the screw downhole pump is designed for dirty water. Its pollution tolerance is up to 20 kg per cubic meter.

It is recommended to use auger equipment in the following cases:

- In the presence of fine sand in the water passing through the bottom filter.

- For pumping in the case of silting or a newly drilled well.

- Very low efficiency - about 65%.

disadvantages

Tip: due to low efficiency it is not recommended to use powerful samples, as there will be too much extra power consumption.

- Unprofitable ratio of size and performance. Powerful models have impressive dimensions, which is absolutely unacceptable for well maintenance. And borehole pumps of low productivity are categorically not suitable for servicing artesian wells.

- Very loud sound effects during operation.

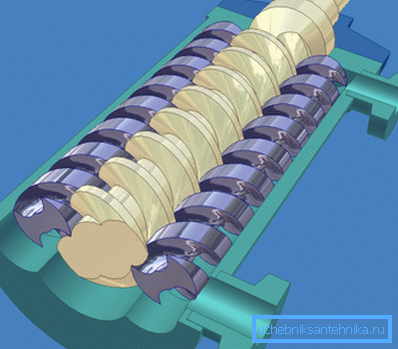

Centrifugal

The basis of such a pump is a wheel with blades mounted in a spiral casing. As it rotates, the water rises along the walls and is pushed out. In this case, the pressure drops at the inlet, and the inside is inversely injected.

Benefits

- High reliability.

- Reasonable price due to the simplicity of the design.

- Automated control.

- Small size, allowing it to penetrate the narrow mines.

- High suction lift. Which makes it easy to do it yourself.

- High efficiency, up to 85%.

All this makes this unit very popular in the field of downhole equipment. But in order to use it more effectively, it is recommended to familiarize yourself with its drawbacks.

disadvantages

- Interruptions in fluid transfer in case of instability of the electrical network resistance.

- Impossibility to start in the event that the water mirror does not reach the inlet. It is necessary to top up H2About through the outlet to start the unit.

- Sensitivity to the presence of sand in the water.

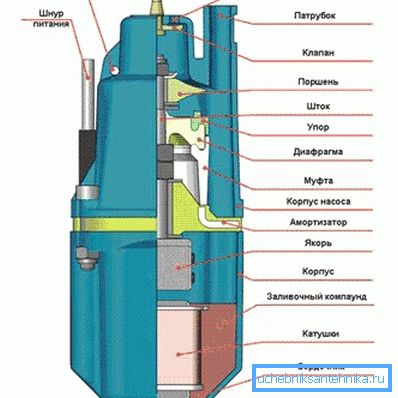

Vibrating

The principle of operation of a downhole pump of this type is based on the formation of a magnetic field when an electric current passes through a coil. The core associated with the rod retracts, flexing the rubber diaphragm.

Water then enters the chamber where the springs start to work. The diaphragm takes its original position, which creates an overpressure, under the action of which the liquid rushes to the point of consumption.

Merits

- Increased reliability due to the absence of bearings and other rotating components that contribute to overheating of the device.

- Long service life.

- Low price.

- Ease of maintenance.

- Low power consumption. For driving one cube of liquid, only 0.2 kW is required.

- Compact size with high power.

Disadvantage

With all the advantages of the pump, working due to vibration, there is a very significant disadvantage. Vibrating, it causes sand and other debris gathered on the bottom filter to settle back into the mine, clogging it up. Ultimately, this may lead to complete cessation of the well.

Tip: It is recommended that the diameter of the mine be made sufficient that the vibrating apparatus does not touch its walls. Then the shedding of sandstone will not occur.

Rod

Borehole sucker-rod pumps operate on the principle of a valve, which is operated manually or rotary. Such a pumping system is often used to remove water from flooded areas of a sea or river vessel as a result of receiving airborne damage.

Plunger-type industrial borehole pumps are widely used in oil production, being installed above an oil well. They are free to pump fluid that is viscous or polluted even by rocks.

In everyday use, it is still possible to find outdoor public water pipes with this principle of operation. Previously, they were more in demand, and today they will be perfectly handed in a country house that does not have electrical wiring. The instruction of their operation implies the absence of automation.

Conclusion

In order for the well to work, providing your house with long-awaited water, a pump installation is required. Today, specialty stores can offer a very wide range of different models based on different principles of work, having different sizes and cost.

The most common are:

- spiral,

- centrifugal,

- vibrating,

- rod

Each of the options has a set of its pros and cons. Therefore, it is recommended to weigh everything carefully, to take into account your needs, the possibilities of maintenance, the size of budget funds and the technical characteristics of the well itself. Then you can make the best choice for your particular case.

The video in this article will acquaint you with additional information on this topic. Good luck with your choice!