Types of well pumps - overview

Own well or a well on the site is an opportunity not to depend on the central water supply, and to always have good quality water in unlimited quantities. But by itself, the water will not flow into the house, for its supply you need an electric pump for a well, the choice of which is not easy.

Selection options

To choose the right water-lifting equipment, you need to know what pumps are for wells, how they differ from each other. On the other hand, for the correct selection it is important to have information about the parameters of the well itself.

This refers to the following characteristics:

- Diameter;

- Depth;

- Filling rate and debit (the amount of water that a well can give for a certain period of time);

- The composition of water, the presence of undissolved impurities in it.

It is necessary to take into account many other factors - the ability to connect pumping equipment to a power source, frequency, frequency and seasonality of use, price. Fortunately, today it is not a problem - the range of such equipment is so rich that everyone can choose the right model.

Types of borehole pumps

All pumps are designed for pumping any liquids or gases. Their classification depends on the pumped medium: they produce water, fecal, drainage, mud pump for drilling wells, etc. We are interested in those who are able to raise water to a certain height and pump them into pipes or tanks.

According to their place of installation, the types of pumps for wells are divided into two large groups - surface and submersible.

Surface pumps

The name itself suggests that the surface or uphole pump for a well is placed on the surface of the earth and is not intended for immersion in water. It consists of an electric motor and a pump with holes for intake and supply of water. A hose is attached to the intake hole, the opposite end of which, equipped with a check valve, is immersed in the well.

Council The quality of the check valve should be given special attention - in case of its depressurization it will be impossible to start the equipment.

Surface pumps are divided into two types:

- Injection pumps for wells are designed to raise water from a relatively small depth (10-15 meters). They consume little energy and are considered the most appropriate for private use.

- Ejector pumps are more powerful, suitable for deep (40-50 meters) wells. But they are also noisier and more energy consuming, therefore they are more often used at industrial water intakes.

Attention! Surface pumps do not tolerate water entering the engine, so they should be installed in a caisson equipped above the well, in a nearby building or under a carport. In winter, in order to avoid freezing of water in the pump, the body should be insulated.

Submersible pumps

These are fully or partially submersible instruments. They allow you to pump fluid from deep aquifers and in their capabilities greatly surpass the mechanisms designed to be installed on the surface.

To provide water from wells use the following types:

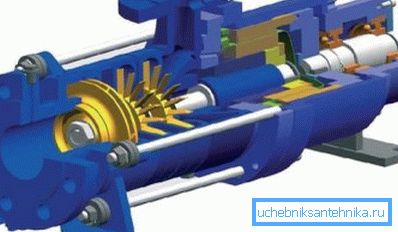

- Centrifugal - used to raise water with a high content of mechanical impurities (sand). Durable, wear-resistant, reliable and high-performance devices capable of servicing a well with a depth of 100 meters or more.

For reference. Often, buyers confuse the name, asking them to sell a vacuum pump for the well. In fact, such a device is not designed for pumping water. Most likely, this refers to a self-priming centrifugal pump that operates with a suction discharge.

- Whirling - used to raise water with a low sand content to a height of up to 100 meters. Submerged in water to a depth of 30 meters from the mirror. The principle of their operation is based on the creation by the impeller of the turbulence, through which the transfer is carried out. Productivity is lower than that of centrifugal counterparts, but the ability to create high pressure even with a small water supply makes them suitable for use in marginal wells.

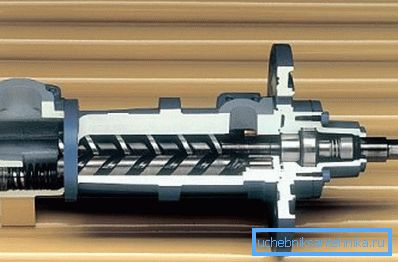

- Screw pumps for wells are the most inexpensive. They can pump water from wells, wells and natural reservoirs from a depth of 15 meters.

All of these devices have good power, but they should be selected, based primarily on the characteristics of the well. For sandy ones, with a small debit and irregular use, it is enough to purchase surface equipment, but a pump for a deep-well artesian well should have increased power and reliability.

Its installation and commissioning is a difficult, responsible business. This may require special equipment - lifting devices, crane installations.

The instruction requires compliance with certain conditions that do not allow overload. Therefore, it is better to entrust the installation of the pump, even if you yourself are well aware of its operation and connection rules.

Hand pumps

A variety of appliances for pumping water can not but rejoice. But what to do if there is no electricity at the site or it is supplied intermittently?

You will be rescued by a mechanical pump for the well. It is driven by manual force - water literally has to be pumped, working with a lever that moves a piston located in the housing.

Depending on the design, hand pumps are divided into piston and sucker-rod pumps.

They work on the vacuum principle.

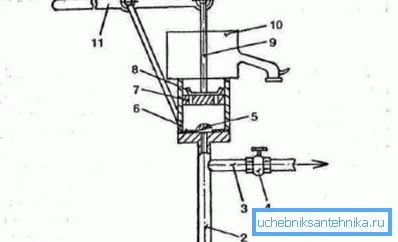

- The design of a piston pump consists of a piston 7 moving in cylinder 6. When the piston moves down, the disk valve 5 in the bottom of the cylinder closes and the piston valve 8 opens and water flows through it into the free space above the piston. When the piston starts to rise, the valve 8 closes, and the raised water column flows into the water intake reservoir 10. As the piston moves upwards, a vacuum area is formed below it, and the valve 5 opens, letting water into the empty space. The movement of the piston provides the rod 9 connected to the lever 11 by the hinge. If under a pump, insert a branch pipe 3 and install a check valve 4 on it, it will be possible to connect an electropump to the well.

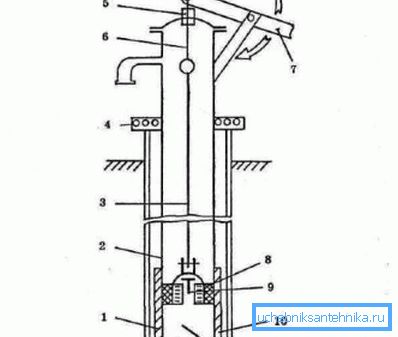

- The well pump for the well is similar. The cylinder 1 on the column of water-lifting pipes 2 is immersed in the well so that the lower suction valve 10 is in the water. The column is fixed on the casing pipe clamp 4, at its upper end is mounted gland 5.

Attached to the rod 3, the piston 8 is lowered into the cylinder so that there is 5-6 cm between it and the valve 10. The rod 6 is attached to the upper end of the rod. It passes through the gland and connects to the lever 7.

When the piston moves down, the valve 10 closes and the inlet valve 9 in the piston itself opens. Water fills the space above the piston and moves with it upwards, while the rarefied space under it is filled with water from the well.

A detailed description of the principle of operation and the above schemes will allow you to make such a mechanism for pumping water with your own hands - with certain skills, it is not difficult. But it should be remembered that a home-made pump for a well is capable of pumping out water from a relatively small depth, not exceeding 10-15 meters.

Conclusion

Choosing water-lifting equipment, well study all its types in order to understand which pump you need. A deeper study of this issue will help the video in this article. We want to recommend paying attention not only to the technical characteristics of the device, but also to its quality and warranty period of work.