Water networks: varieties, components and design issues

Water is transported to consumers by water pipes and water supply networks. These structures must comply with the requirements of efficiency and reliability. This is achieved with proper choice in the design of the pipeline route and the network layout, material and section of pipes, as well as their modes of operation.

When selecting, assigning and using sites for water conduits, it is necessary to adhere to land legislation and certain regulatory documents.

Varieties of water networks

All water supply systems are divided into external and internal networks.

The outer part of the systems

Stretch water in 1, 2 and more "threads". The best option is to install them on a fairly elevated area, having a minimum number of structures, in areas that are convenient for maintenance and repairs.

In order to ensure the planned level of water supply to consumers, between paralleled conduits equip switch. Along the length of the route and on the site of the serviced object storage tanks can be placed.

The classification of water supply networks divides them according to the method of transporting water to pressure and non-pressure.

- The fluid is pumped through pressure networks with pumps or through pressure differences. It is created between the piezometric mark of the water level at the source and the calculated piezometric mark at the point of intake. The first conduits are injection, the second - gravity-pressure (gravitational-pressure).

- In non-pressure (gravity-gravity) water lines, their internal space (section) is not fully used. The scope of their application is not so wide in comparison with the pressure ones.

Note! The feasibility of laying free-flow conduit depends on some points. For example, the difference in the level of marks of the beginning and the end of the fluid supply, the relief of the region, the distance between the supply and collection nodes.

The use of non-pressure pipes reduces the cost of water pipes. But the cost of the route may increase due to the increase in its length due to the need to provide the required slopes.

The system configuration may depend on such factors:

- surface shape and layout of the object;

- the presence of artificial and natural obstacles;

- relief of the region;

- the location of the main consumers of the resource;

- water source locations, etc.

For this reason, the network configuration can be branched, ringed or mixed. Ring counterparts are the most expensive, but have the highest reliability.

The instruction notes that the threads of the system delivering the main volume of water are trunk. Without being tied to the appearance of the network, the highway should always be laid on the basis of the direction of the main water flows. They should cover the entire locality.

What are external networks

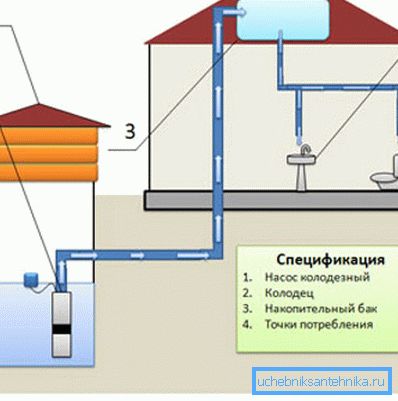

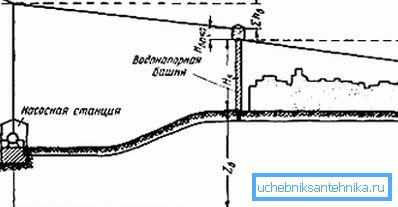

The main elements of pressure networks can be:

- accumulation tank;

- pumping station;

- pressure pipeline (water line);

- water construction (tower);

- lines of hydrostatic and hydrodynamic pressure;

- pressure underground tank;

- camera to switch.

Pipe material for conduits is selected when designing systems and depends on the conditions of their use. This may be steel, plastic, reinforced concrete, asbestos cement.

The most commonly used diameters of steel pipe products are presented in the lower table.

| Pass conditional, in cm | The wall thickness of the pipe, in mm | Weight per meter in kg | ||||

| lungs | ordinary | reinforced | lungs | ordinary | reinforced | |

| 0.6 | 1.8 | 2 | 2.5 | 0.37 | 0.4 | 0.47 |

| 0.8 | 2 | 2.2 | 2.8 | 0.57 | 0.62 | 0.74 |

| one | 2 | 2.2 | 2.8 | 0.74 | 0.8 | 0.98 |

| 1.5 | 2.35 | ? | ? | 1.1 | ? | ? |

| 1.5 | 2.5 | 2.8 | 3.2 | 1.16 | 1.28 | 1.43 |

| 2 | 2.35 | ? | ? | 1.42 | ? | ? |

| 2 | 2.5 | 2.8 | 3.2 | 1.5 | 1.66 | 1.86 |

| 2.5 | 2.8 | 3.2 | four | 2.12 | 2.39 | 2.91 |

| 3.2 | 2.8 | 3.2 | four | 2.73 | 3.09 | 3.78 |

| four | 3 | 3.5 | four | 3.33 | 3.84 | 4.34 |

| five | 3 | 3.5 | 4.5 | 4.22 | 4.88 | 6.16 |

| 6.5 | 3.2 | four | 4.5 | 5.71 | 7.05 | 7.88 |

| eight | 3.5 | four | 4.5 | 7.34 | 8.34 | 9.32 |

| 9 | 3.5 | four | 4.5 | 8.44 | 9.6 | 10.74 |

| ten | four | 4.5 | five | 10.85 | 12.15 | 13.44 |

| 12.5 | four | 4.5 | 5.5 | 13.42 | 15.04 | 18.24 |

| 15 | four | 4.5 | 5.5 | 15.88 | 17.81 | 21.63 |

Internal water supply

The internal water supply system of buildings and objects is called a set of equipment, components and devices that provide the resource from the external network and its delivery under pressure to water dispensers.

The device of a water supply network in buildings is as follows:

- one or more inputs;

- one or more gauges;

- distribution and supply pipeline;

- shut-off and control valves.

- sometimes the system includes pumps for increasing pressure and filters for softening, deferrization, discoloration, etc. water.

The internal water supply system can be connected with its own hands to the municipal supply network of the settlement or be powered from an autonomous water source (surface or underground).

According to their purpose, the water supply systems of facilities and buildings are divided into industrial, drinking and fire fighting systems.

- Production networks supply water of different quality for the technical needs of consumers (equipment cooling, manufacturing of products, for example, concrete, food products, etc.).

- Fire suppressants serve to extinguish fires and prevent their spread.

- Domestic-drinking networks are designed to deliver drinking-quality water. In addition, the resource is used for cooking and hygiene.

According to the method of using the resource, the system ensures the supply of direct-flow, reverse or repeated. In domestic networks, the first variety is common, the latter two are more and more in demand in production.

Design problems

The primary task of design is the routing of the water supply network, which involves drawing pipelines on the plan.

Note! It is carried out on the basis of the conditions for creating a sufficiently reliable system. At the same time the cost of its construction should be the lowest.

When tracing taken into account:

- location of the water source and its consumers;

- relief of the region;

- location of rivers, ravines, parks, streets, buildings, structures and other artificial and natural obstacles to the installation of the pipeline.

Tracing is carried out on the topographic map of the region along the shortest path, bypassing obstacles.

Note! The resource should be delivered to users not only in the required volume, the pressure should also be sufficient. It should be enough to lift water to the points of placement of water-folding devices.

For this purpose, you need to constantly maintain free pressure in the water supply network. By this is meant the difference between the mark of the liquid level (piezometric) in the pipeline and the level of the soil surface.

On free pressure

A free head should be created that is sufficient along the entire length of the trunk network, even at the highest and most distant points.

In such unfavorable areas, the pressure should not fall below the values specified in the regulations.

- So, in order to correctly determine the height of the water tower, it is necessary that the dictating point of the water supply network be found - this is the area to which it is most difficult to lift water.

- This place is determined by calculations.

- For this purpose, several unfavorable areas are selected on the distribution pipeline distribution trace. One of them will be dictating.

- Further, a “general diluting point” is determined, which is closest to the problem ones. From it the liquid and is fed into them.

- Determining the pressure mark (piezometric) at the general distributing point for lifting the resource to selected problem areas and comparing the parameters of their piezometric marks, the experts calculate the dictating point. For her, the value of the label will be higher.

In the course of this work, a piezometric graph of the water supply network is drawn. It shows the pressure change along the length of the conduit.

One of the important design tasks is to detail the system. It consists in the selection and specific placement in the network of water wells, fittings, fittings, etc.

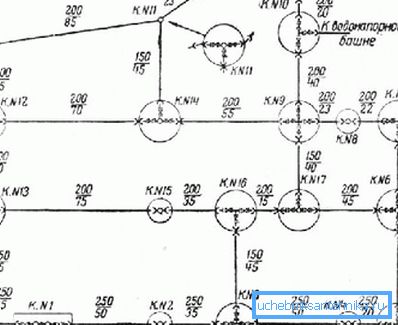

The detailing of the water supply network is carried out according to the chosen option of the water supply scheme. This is done when the hydraulic calculation of the system has already been carried out, the actual values of resource consumption have been found, the material and the diameter of the pipes have been determined. Detailing designers produce on working drawings. With the help of symbols, the fittings, fittings and other elements from which the system assemblies are assembled are shown on them.

Some legal issues

If the created water supply system will be connected to the utility network, you must first obtain the preliminary technical conditions in the regional Vodokanal.

To obtain them, you must collect and submit such documents.

- Application for TU.

- The form in which the balance membership of water supply networks will be described.

- Information about the applicant: passport, postal and real residence address, contact information.

- Title deed on a plot of land.

- Plan the boundaries of the territory in which water supply will be constructed.

- Permission for such use of the plot.

- Information about the planned timing of the introduction of the future object in operation.

- Calculations of the volume of the required resource (i.e. planned loads).

- Data on construction parameters.

Technological connection to the water supply network of the finished object is carried out within the boundaries of the land plot. This is done within 18 months, counted from the date of signing the connection agreement.

It should be noted that, at the same time, the boundaries of the division of the operational responsibility of water supply networks should be carried out in accordance with the Decree of the Government of the Russian Federation No. 167 “Rules for the Use of Communal Water Supply Systems and Sewerage in the Russian Federation”.

Conclusion

Water supply networks are complex hydraulic structures. There are many types of them, which should be selected based on the purpose of the system and the conditions of its operation. The video in this article will develop its theme.