Water supply from the well: schemes and materials

Is it difficult to mount a water supply system from a well with your own hands? In this article, we are to get acquainted with the methods of organizing the input of cold water into a private house, the equipment used for this purpose and the materials used.

Wells and wells

To begin to eliminate the confusion in terminology.

The water well is often understood as two completely different things:

- High water well, allowing to use for domestic (and sometimes drinking) needs groundwater.

To clarify: in a garden partnership or residential settlement, water from a well when used for drinking needs to be filtered and boiled. The reason - outdoor toilets and cesspools, the drains of which go into the ground.

- Water well, in which the discharge from the water main to the house or a group of buildings.

We will consider both options.

Water well

Regulatory requirements

They are contained in SNiP 2.04.02-84, which establishes the rules for the installation of external water supply networks.

Select from the text of the document highlights.

- Shut-off valves in sections of the main water supply system are located in wells. It is clear that we are talking about underground laying; however, in accordance with clause 8.42, it is actually obligatory: cold water pipes should be laid half a meter below the freezing level.

- When crossing the pipeline under the railway on both sides of the transition, wells with shut-off valves are provided.

- Designed for valves and manholes on the water supply should be built with the following minimum distances:

| Objects | Minimum distance, mm |

| Well walls and pipes with a diameter? 400 mm | 300 |

| The same diameter is 500-600 mm | 500 |

| Also, >600 mm | 700 |

| Walls of a well and the plane of a flange at diameter of pipes? 400 mm | 300 |

| Also, > 400 mm | 500 |

| Walls of a well and the edge of a bell turned to them at diameter? 300 mm | 400 |

| Also, > 300 mm | 500 |

| The bottom and the bottom of the pipe in diameter? 400 mm | 250 |

| The same diameter is 500-600 mm | 300 |

| Also, > 600 mm | 350 |

| Well wall and top of retractable valve stem | 300 |

| Well wall and valve stem with non-rising stem | 500 |

| Bottom and well cover | 1500 |

- Inspection wells should have a diameter of 1 meter, rise above the surrounding ground at least 0.2 m, be supplied with a waterproof blind area and a clay castle.

- The distance between the water supply wells according to SNiP 2.04.02-84 during the transportation of chlorine water should not be more than 30 meters. But for drinking-water pipelines it is indicated indirectly: in paragraph 8.10 it is written that the length of the repair section when laying in one line should be no more than 3 km, when laying in two lines or with the possibility of switching - no more than 5 km.

However: the requirements for the installation of fire hydrants can also influence the location of wells. They must ensure the supply of water to extinguish any building in the area serviced by running water.

Device

There are no strict requirements for the installation of a well, except for the presence of a draining bottom and a height of at least one and a half meters.

Common sense, however, suggests a couple more points:

- In the area of pedestrian or car traffic, its cover must have sufficient strength to withstand the load without destruction.

- The walls of the well must provide adequate bearing capacity. Obviously, you should not cover polyethylene wells for plumbing with concrete plates.

The simplest solution - the rings of the COP and the stove with the hatch PPL; However, when installing a well on a previously constructed water supply system, installing rings is quite problematic. In this case, the walls are poured with concrete in wooden formwork with reinforcement with mesh or rod; more rarely, they are laid out of red solid brick on a concrete pad around the perimeter.

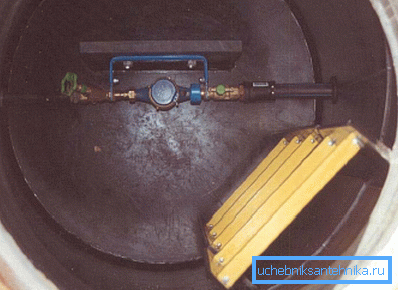

What equipment should be in the well?

The required minimum is:

- Valve element - gate valve, screw valve or most sensibly, ball valve.

- Sump (coarse filter).

- Water meter.

In addition, it would be a good idea to install:

- The second tap after the counter. He will allow to remove it, without losing all volume of water in a water supply system.

- Check valve for pressure measurement. It will help you determine the place where you have a problem with the cross, with a sharp drop in pressure.

Entering to the walls of the house is usually laid with a polyethylene pipe below the level of freezing. Its diameter is determined by the peak water flow:

| DU (or internal diameter), mm | Water consumption, l / s |

| ten | 0,120 |

| 15 | 0.360 |

| 20 | 0.720 |

| 25 | 1,440 |

| 32 | 2,400 |

| 40 | 3,600 |

| 50 | 6,000 |

The choice of polyethylene is due to its elasticity at low temperatures: even if the water in the pipe freezes, it will not be damaged and after defrosting will return to its original size. In addition, the input does not need to be laid strictly in a straight line: bends are quite acceptable.

Water supply from the dacha well

The water supply system from the well at the dacha can be built according to two schemes - with a hydraulic accumulator and a cumulative capacity.

The advantage of the first scheme is that it does not need to be installed on an elevation (attic, a welded support or a natural elevation) tank of significant volume. But the use of storage capacity will allow you to do without a stationary pump: the tank can be dialed once a week through a hose.

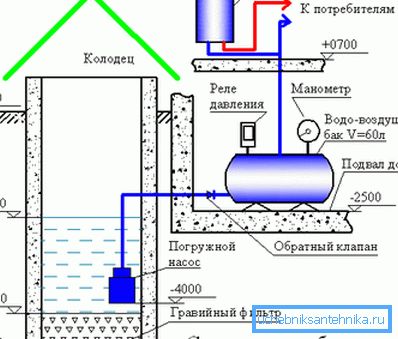

Circuit with hydroaccumulator

It includes:

- Submersible pump.

- Immediately after it is installed a check valve that prevents water from pouring out of the water pipes after the pump stops.

- Putting water in the house.

- The hydroaccumulator installed in the room is a metal container divided by a rubber membrane into compartments for water and air. Fluids are almost incompressible; air cushion allows you to create excess pressure required for the operation of sanitary devices. In addition, the hydraulic accumulator contains a supply of water, allowing the pump to stand idle most of the time.

- Pressure sensor with a switch that turns the pump on and off when the pressure thresholds are reached.

- Dry running sensor stopping the pump when the well is empty.

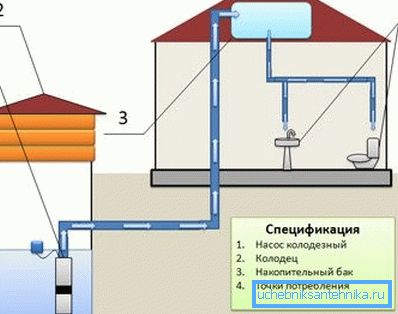

Scheme with cumulative capacity

As already mentioned, in this case the device of the water supply system from the well can be considerably simplified, using not a stationary pipeline to fill the tank, but a regular hose. The internal water supply of the house and the pipes for irrigation of the area are connected to the outlet of the tank.

Useful: polyethylene water tanks are sold already equipped with a drain pipe size of 15 or 20 mm.

Is it possible to automate the filling of the tank in the event that it is equipped with a stationary filling pipe?

Of course. It is enough to put a filler pipe in its neck, and place two level sensors with floats inside the tank. If the size of the neck does not allow fixing them directly on the inner wall, a simple instruction will help: fix the sensors on a steel pipe with a tripod base and put it on the bottom of the tank.

About pumps

Both described schemes imply the use of a pump.

How to choose this device?

- Instead of a set of a submersible pump and a hydroaccumulator, a pumping station designed for surface installation can be used with a short distance to the water mirror (no more than 7–8 meters). The price of these devices starts from about 4 thousand rubles. The only drawback of the solution is a noticeable noise level at work.

- For clean water (the amount of impurities is not more than 30 g / m3), with a large depth of the well, a vortex pump with one impeller will be suitable. It boasts high pressure and performance due to the minimum clearance between the impeller and the cochlea.

- If the water contains a lot of sand and other suspensions, it is better to get a multi-stage centrifugal pump. The increased clearance between the centrifugal impeller and the casing is compensated by the sequential operation of several stages consisting of an impeller and a diffuser: each of them increases the head by a fixed amount.

Please note: vibration (diaphragm) pumps, despite their low prices, are not suitable for our purposes. Membranes in them require frequent replacement. Worse, the vibration causes accelerated silting of the well with a decrease in water flow.

Conclusion

We hope that we were able to answer most of the questions that have accumulated in the reader. If anything in the material remains unclear - perhaps the video in this article will help solve this problem. Successes!