Water tap: destination, species, features

Construction of the water supply system is impossible without the use of valves and fittings, the most prominent representatives of which are taps for water supply. These devices are used to shut off or adjust the water pressure in the system or its part, as well as to equip water intake points. We will consider the device and features of water taps.

Tap for plumbing

Purpose

In any water supply networks - central, local or autonomous - the locking and regulating equipment is used. The most common type of such equipment is a tap for water supply.

The device is designed to implement the functions of adjusting the pressure and capacity of the pipeline by changing the cross-sectional area of the pipe channel lumen.

Products can perform two main functions:

- Shut-off function. The valve has two positions - “open” and “closed”, and serves to block or unlock the pipe channel. Basically, the shut-off valves have a spherical version and a small angle of rotation of the handle;

- Adjustment function. Here, the closed and open positions are extreme points, and the device allows you to smoothly change the cross section of the lumen between these extreme positions. Such faucets are used in sinks and sinks, as well as in channel performance. May have different designs.

Shut-off and shut-off and adjusting valves are installed on the main pipe inlets at the facility, in each separate room, at branching and intersection sites, before and after plumbing fixtures and metering equipment, before and after pumping equipment, at water intake points.

Such massive use is explained by the fact that the sanitary equipment often fails and requires repair, in addition, often preventive measures are taken that require shutting off the water supply. With the help of valves, you can cut off the network area or the device from the system and calmly replace it without draining the water.

Note! A well-constructed water supply system allows you to turn off any device or part of the network using a crane.

Device and Variations

Classification of devices can be conducted according to different criteria.

To begin with, you should separate them by purpose:

- Products for domestic needs. These are the usual faucets on sinks and bathtubs, kitchen appliances, etc .;

- For household needs. These are taps mounted on the end of the pipe for connecting watering hoses, watering and other similar needs. Can be ball or valve;

- For the needs of the water supply system. These devices are built into the system and have a clutch version (most often). With rare exceptions, these are ball valves.

For domestic use is not simple construction, and mixing. They allow you to adjust not only the pressure, but also the temperature of the water by mixing hot and cold streams in different proportions.

Here are possible solutions:

- Two-valve. The mixer has two separate valves for hot and cold water. Adjustment is made by both sheep;

- Single lever or surgical. On the mixer, there is one handle that controls the proportion of the mixture and the pressure;

- Automatic. The mixer is a three-way valve with a thermostat, and the opening is done with a conventional ceramic bush or servo actuator at the command of a motion sensor. Such designs are still distinguished by too high a price.

There are four types of designs: worm, ball, ceramic valve axle boxes and ceramic lever cartridges for the mixer.

The first ones are morally obsolete and practically not used, since they are the least reliable and require frequent replacement of rubber gaskets.

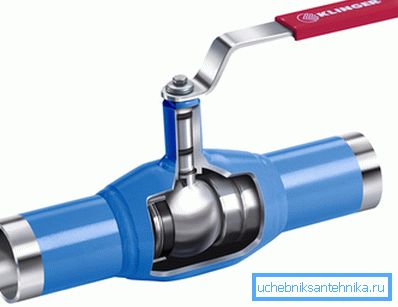

Ball constructions are arranged simply: a spherical plug with an axial slot is installed in the coupling housing, which fits tightly to the saddle in which it is located. A spindle is attached to the ball. With the help of the spindle, we can turn the cork either by a slot to the channel lumen or by a side without a slot.

In ceramic locking mechanisms, the same principle is used, only the plate does not move, but one plate relative to another. Ceramic bushings, as well as cartridges, are distinguished by high reliability, smooth running, and quiet operation. However, they are sensitive to water quality and require the installation of cleaning filters.

Household cranes are usually arranged simpler - they do not have a mixer and are a simple case with a valve-type locking mechanism. In modern models, a ball mechanism or a ceramic crane box is installed, the worm valves are gradually being squeezed out of the market.

I must say that the ball and valve mechanisms are not only used in water supply networks: they stand on all types of pipes, so the buyer often cannot understand the difference between a gas tap and a water tap. Their designs are the same, only the materials and some nuances differ.

Note! Despite similar designs, each model should be used strictly for its intended purpose. Otherwise, any complaints about the quality of work will not be considered.

Installation

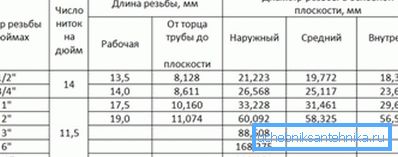

The ball valve coupling design is very easy to mount. First you need to choose the size, for this we use the table:

Then at the end of the pipe cut the external thread with a die. The thread is compacted with flax and sealing paste, then the valve is screwed with a 4–4.5 turn key. Installation does not differ from installation of the usual coupling.

A faucet with a mixer is also not difficult to install. There are models with wall mounting and mounting on the sink.

The installation instructions for the wall mixer look like this:

- At the ends of the removed pipes, we cut the internal thread and screw the eccentrics into them. Seal the thread with flax or tape FUM;

- We assemble the mixer housing according to the manufacturer's instructions and bring it to the eccentrics. We expose them so that they coincide with the cap nuts of the input channels of the device and are on a strictly horizontal level;

- We twist decorative eccentrics on the eccentric threads;

- We put on the case on the ends of the eccentrics and tighten the union nuts with a plumbing key. Tighten them strongly, otherwise you will damage the rubber gaskets;

- Connect the flexible hose of the shower head, the position sensor of the faucet (if necessary) and other parts. We supply water and experience the work.

Note! Before installing the mixer, make sure that the rubber gaskets in the cap nuts are present, as they sometimes fall out.

Conclusion

Shut-off and control valves are a necessary and important element of any water supply system. Installing a faucet on 15 or any other is not difficult, as can be seen with the help of the video in this article.