Water valve - views and their features

Water valves are a special type of water fittings that is used as a shut-off or control device. Therefore, they are necessary in every external and internal water supply system. Below we consider what are the valves for plumbing and their features.

General information

As a rule, these valves are used in water pipes to block flow, however, it can perform other functions:

- Regulate head flow;

- Redirect stream (refers to three-way cranes).

In internal systems, stop valves are usually installed in front of each sanitary fixture, which allows it to be repaired or replaced. In addition, a common faucet is installed at the entrance, with which it is possible to cut off the water supply in the whole apartment or house.

Main differences

Considered products differ in several parameters that must be considered when choosing them.

These parameters include:

- Type of valves;

- The materials from which the product is made;

- Specifications.

Note! The main characteristic of the valve is the diameter of the inlet and outlet nozzle. This parameter is indicated on the body. For example, the marking of a faucet 3-4 indicates a diameter of three quarters of an inch, i.e. 1.9 cm

Types of locking mechanism

By type of constipation, all water valves and taps are divided into several types:

- Valve;

- Ball;

- Cork.

Below is a detailed look at the features of all types of these devices.

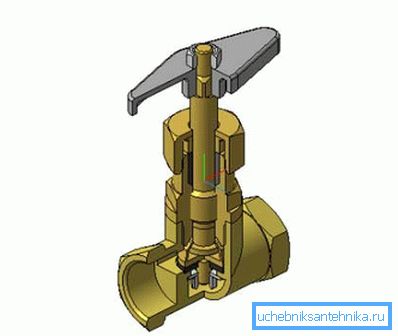

Valve

Valve taps are the usual locking mechanisms. The principle of their work is based on blocking the passage with an elastic gasket installed on the rod. The position of the rod is adjusted by a handle-flywheel using a worm gear.

Thus, as the handle rotates, the stem rises, causing the water passage to open.

Among the advantages of this mechanism are:

- Ability to withstand high pressure;

- The ability to control the flow;

- Ease of Management;

- The possibility of repair.

Along with the advantages, these products have some disadvantages:

- The gasket quickly fails, as it is in contact not only with water, but also with a metal surface. True, you can replace it yourself. As a rule, a device drawing includes an assembly drawing of a water valve, which shows how to disassemble the mechanism and replace the damaged parts.

- To fully open or close the aisle, you must do a few turns with a flywheel with your own hands, which is not very convenient.

- The mechanism is less durable than other types of fittings.

For these reasons, these taps have recently been installed quite rarely, only in those cases when it is necessary to regulate the flow.

Tip! To prolong the life of the gasket, do not apply force when closing the aisle.

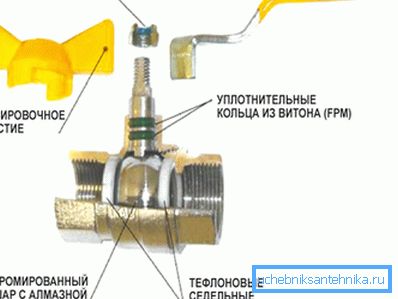

Ball

Ball valves are the most common lately. This name they received as a result of the fact that the locking mechanism is made in the form of a ball with a through hole. To shut off the flow, the ball is turned by a hole perpendicular to the pipeline.

Plumbing ball valve has several advantages, such as:

- Durability due to the simplicity of the mechanism;

- Tightness with closed passage;

- To open the passage, you need to turn the knob only 90 degrees;

- Affordable price;

- The ability to use in conjunction with servos and other devices that allow you to control the mechanism remotely or install it in the automatic overlap flow systems. (See also the article How to choose a mixer: features.)

As for the shortcomings, they are few:

- The instruction manual of the device implies its use only for complete overlapping or opening of the passage, i.e. It can not be used to adjust the flow. Otherwise, the mechanism quickly depressurized.

- In case of failure of the mechanism it can not be repaired.

Most often, this type of reinforcement is used in plumbing systems.

Cork

The device of a cork-type tap valve resembles a valve tap, the only thing that is blocking the flow is carried out by means of a conical plug, which is attached to the stem. When lowering the rod, the stopper enters the hole and tightly closes the passage.

It should be noted that in recent years such fittings are rarely used in water supply systems, since instead of it, more durable ball valves are installed.

Materials

The material from which the product is made is an important parameter, since its cost, durability and appearance depend on it. Below we consider the features of the most common materials:

| Brass and bronze | Products from this material are the most expensive, but at the same time the most durable. This is due to the fact that scale practically does not settle on the walls of a brass or bronze case. |

| Stainless steel | Stainless steel fittings are cheaper, however, its service life is less, since scale builds more strongly on stainless steel. |

| Plastic | Plastic devices are usually installed in plastic piping. Since plastic is not susceptible to corrosion and scale does not settle on it, plastic taps are sufficiently durable. |

Here, in fact, all types of plumbing valves, which are currently used.

Conclusion

As we found out, each type of valve has its own characteristics. Therefore, for different cases use different types of fittings. However, the most common in plumbing systems are still ball valves.

From the video in this article can be found with some additional information on the designated topic.