Water wells: requirements, materials used, installation

What should be the water well? What materials can its walls be made of? Is it difficult to build this structure with your own hands or install a ready-made solution?

In the article we will try to find answers to this series of questions.

General requirements

Let's start with the formal requirements for wells.

There is no separate SNiP for installation of water wells; However, a number of requirements are quite clearly stated in the sanitary norms and rules for the number 2.04.02-84, regulating the construction of external water supply networks.

- The height of the working part of the well (from the surface of the drainage to the cover) should not be less than 1.5 meters.

- For a track with a diameter of up to 400 millimeters, the minimum distance from the pipe to the walls of the well is 0.3 meters. For a diameter of 500-600 mm, it increases to half a meter, and with a track diameter of more than 600 mm - up to 0.7 m.

Photographer's comment: alas, the SNiP does not clarify how this distance is measured in round wells.

- Pipe flanges with a diameter of up to 400 mm should be at least 30 centimeters from the wall. With a diameter of more than 400 millimeters, the distance increases to half a meter. The instruction is connected only with the convenience of installation work: with a large flange size, thicker bolts are used, which often have to be moved using a long lever.

- The distance from the edge of the socket facing the wall for a diameter of up to 300 mm is at least 0.4 meters, for a diameter of more than 300 mm it is half a meter.

- The bottom surface of the pipe (route or entry into the house) from the surface of the bedding should be separated:

- With a diameter of 400 mm - 25 centimeters;

- With a diameter of 500-600 mm - 30 centimeters;

- With a diameter of more than 600 mm - 0.35 meters.

- To descend into the well of its wall, it is recommended to equip it with corrugated steel or cast iron brackets. However, it is permissible to use a portable ladder - a side or folding one.

- The use of a double insulated cover for the well is not mandatory and is used if there is a technical justification (if in a region with strong frosts the construction of the water supply well provides for its depth not much lower than the level of soil freezing).

Materials and construction features

What can be the walls of the well?

Reinforced concrete

It is from it that the walls of wells are most often made for servicing apartment buildings. However, private owners concrete wells are also built; but if rectangular or square monolithic structures (they require simpler formwork) are often constructed to enter water in a private house, organizations follow a more technological scheme using ready-made rings.

It is curious: in the annexes to the normative documents, it is possible to find the estimated norms for basic materials and works. For example, the estimate table of water wells for number 22-04-003, attached to HESN-2001-22, contains a complete list of works and materials for the device of a prefabricated monolithic well with a volume of 10 cubic meters.

What does independent construction look like? In the same way as in the construction of a concrete septic tank or cellar.

The only difficulty is that the design of the formwork must provide holes for the trays of the route and entry.

- The foundation pit comes off, the size of which slightly exceeds the future size of the well.

- The bottom is filled with about 20 centimeters of rubble or sand. The bedding will become the basis for the walls and perform the function of drainage.

- The walls of the pit overlap waterproofing material - roofing material or polyethylene. He, among other things, will not give cement jelly uselessly filtered into the soil, thereby reducing the strength of the structure.

- Armor frame is being constructed. Ideally, corrugated fittings are knitted with annealed wire, however, finished mesh or metal trimming can be used.

- Formwork is being built. Material - boards, OSB, DSP or plywood.

- Formwork is poured in layers with M200 concrete or independently prepared solution. Composition - 1 part of cement, 3 parts of sand and 3 parts of crushed stone. Every 20-25 centimeters concrete is spun with rebar.

- From above the finished slab is laid with the well cap.

Brick

The construction of brick walls is not much more complicated; however, the size of the pit in this case will be somewhat larger. The reason is that exterior waterproofing is highly desirable for brickwork. It is performed by bitumen mastic in several layers..

Attention: for laying only red clay brick is used. Silicate is rapidly destroyed in a humid environment.

The masonry itself is quite traditional: half-brick, with horizontal rows of dressing at least a quarter of the brick's length. Cement-sand mortar is used as a binder in a ratio of 1: 3; sand is pre-screened. The thickness of the seam - the standard 12 millimeters.

Plastic

Plastic sewage and water-ready wells are beneficial in that they can save a lot of time. Their walls are, as a rule, a thick corrugated pipe made of polyethylene or polypropylene with taps under the trays and sealing rings.

The price of these products, however, is slightly higher than the cost of building materials in the case of self-construction of concrete or brick. A well two meters high and with a diameter of 70 cm will cost approximately 15-17 thousand rubles.

How is the installation of a plumbing well made of plastic?

- The ditch comes off is somewhat larger compared to the well size. The stock in size should be approximately 20 centimeters in all directions.

- A sand bedding is formed.

- Plastic construction falls to the bottom of the pit.

- In the presence of the priming chamber (weighting agent, capacity, preventing the ascent of plastic in wet soil), it is filled with concrete.

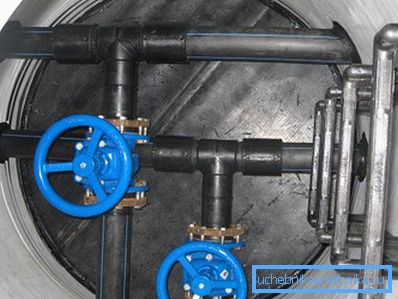

- All communications are mounted: stop valves, a well prefilter filter and a water meter are connected to the pipeline outlet.

- Backfilling is performed. For wells of increased rigidity (with a corrugated surface), previously excavated soil with tamper every 20 centimeters is used. For structures with smooth walls, backfilling is performed with a cement-sand mixture in a ratio of 1: 5.

Conclusion

The video in this article will traditionally offer the reader additional materials. Successes in construction!