Watering can for a country shower: features of plastic,

In the warm season, many owners of summer cottages and country houses of seasonal residence need to build a summer shower on their own plot. In itself, the design of the summer shower is extremely simple, and is available for self-construction to any home craftsman, besides, our website has step-by-step instructions with a detailed description of the manufacturing technology of this device.

Despite this, during the construction process after the installation of the storage tank, many owners of the dacha plots are wondering about choosing the most suitable watering can for the dacha shower with a crane, which would be distinguished by high reliability and fully correspond to their functional purpose.

Overview of watering cans for the dacha shower

Currently, in the building and gardening stores, you can find a large number of various water-dispersing nozzles, which can differ from each other in the production material, the outer diameter of the head and the number of outlets, the docking size and method of connection to the storage tank, the type of stop valve valve, as well as many other parameters.

In order to help the reader make the right choice, this article will provide a brief comparative overview of the various models of this type of product, and indicate the main advantages and disadvantages of a particular model.

Plastic shower heads

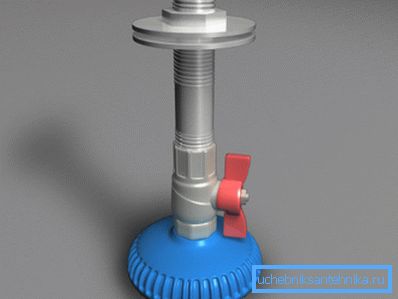

The most common commercially available plastic shower for a summer shower to the country, is a hollow tube with an outer diameter of 25-32 mm, made of polypropylene or low-pressure polyethylene, on one side of which a thread is cut to attach to the storage tank, and on the other hand The water diffusing head is located with a diameter of 80 to 120 mm.

In the lower plane of the head, a plate with a large number of small holes is fastened with a threaded connection, due to which a continuous stream of water is dispersed into a multitude of thin streams.

A plastic tap is installed in the middle of the tube to adjust the water pressure, which, as a rule, has a ball locking mechanism. The diameter of the connecting thread is made according to certain standards, and depending on the model, it can have dimensions of 1/2 "; 3 \ 4 "or 1", therefore, suitable for connection to most types of sanitary valves.

Among the main advantages and disadvantages of such models, one can single out their main consumer qualities.

- Polymeric materials have a significantly lower cost compared to metal., therefore, the price of plastic models compares favorably downwards.

- Plastic products are absolutely not subject to corrosion., and less susceptible to the deposition of lime salts from the water, so the service life of plastic watering cans, with proper use, can last tens of years.

- Polypropylene does not lose elasticity, even at low temperatures, therefore, a shower watering can made from this material will not collapse when water freezes in winter.

- Polyethylene and polypropylene have low friction, Therefore, plastic pipes have a high capacity, and ball valves made of these materials do not need additional lubrication throughout the entire period of operation.

- Of the negative qualities of plastic models, it should be noted their lower mechanical strength, compared to metal products, as a result, they do not tolerate sharp shock loads.

Note! Some models of plastic watering cans, in the original configuration, instead of connecting thread in the end end, can be equipped with a universal herringbone, which is used to connect to the garden hose.

Metal shower heads

A metal shower head with a water supply button, or with a ball shut-off valve, has a similar design, but is most often made of stainless steel or brass coated with a decorative protective layer of nickel-chromium spraying.

In order to give an objective assessment of such metal products, their main positive and negative properties should be considered, compared with the consumer qualities of plastic models.

- Metal shower head for giving has a more expensive and noble appearance, therefore, it looks more solid, but its cost, respectively, is significantly higher than that of plastic models.

- Stainless steel and brass resist corrosion well, and besides, they have high mechanical strength, therefore, the service life of such products is also quite high.

- All metals and alloys have high rigidity., therefore, in the event of freezing of water inside this device, the walls of the tube or shower head may break due to the expansion of ice. For this reason, in the winter time it is necessary to completely drain the water from the tank for the shower, or to clean the shower head for storage in a heated room.

Note! In addition to metal and plastic watering cans, there are also combo models on sale that can have a spray head, a plastic tube, and a metal ball valve, or vice versa.

Installation of a shower water dispersing head

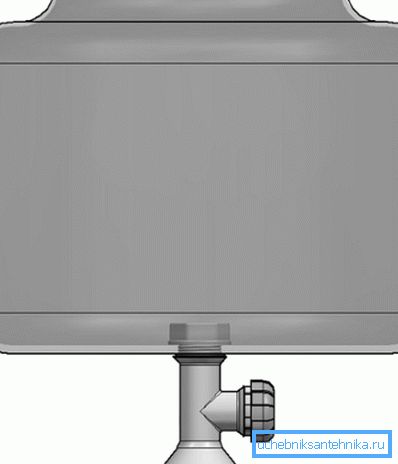

Most types of modern cumulative water tanks, in the bottom of the bottom have a drain hole with threaded threads of a certain diameter. In order to install a standard watering can in such a tank with your own hands, it is enough to wrap its tube in the hole along the thread, having previously installed a rubber gasket.

In the case of using a non-standard storage tank, in order to install the shower head, you need to proceed as follows:

- At the bottom of the bottom of the water tank, drill a hole equal to the diameter of the threaded nipple and, after drilling, process a hole with a round file to remove the burrs.

- Put a rubber or silicone gasket on the threaded fitting of the shower head and install it in the hole outside the storage tank.

- From the inside of the tank, through the filler hole, install a second gasket on the threaded nipple and screw the clamping nut on top.

- Fill the tank to the maximum level, and make sure that the installed shower head does not allow water to pass when the valve is in the closed position.

Conclusion

During the long-term operation of a summer shower, the small holes of a water-diffusing plate may eventually become clogged with sand, rust, or other solid particles, therefore, from time to time, it must be disassembled and cleaned.

To get more detailed information about this device, you can also watch the video in this article or read other materials of similar subjects on our website.