Watering can for a shower with his own hands - how to

Very often, when constructing summer shower structures, the question arises of acquiring a watering can with the necessary parameters, since the standard options have approximately the same configuration and may not fit these or other structures at all times. At the same time, it is important to carry out work with high quality, so that a self-made shower can not be inferior to ready-made factory options and serve as long as possible, this is what we will consider in this article.

What may be required for the work

To begin with, we will look at what products will be needed for assembling the structure in certain conditions, the list may vary depending on the system configuration, we will touch on the most popular nodes:

| Spray | For these purposes, suitable and the old design, which was replaced during the repair and lay in the pantry or basement. If it is not available, then the simplest solution would be to purchase a plastic sprayer, its main advantages are low price and excellent performance properties, because polymeric materials are not subject to corrosion, which is very important when used outdoors |

| Crane | Again, you can choose a variety of available constructions: from the old ball systems to any other options. The most important thing is the operability of the system, so everything you can find is suitable. If there is nothing, then buy a faucet in the plumbing shop, the cost of this type of product is low, so you will not incur any big expenses in any case. |

| Trumpet | Most often, either pieces of a metal pipe are used, or ready bevels are purchased (wagon, this is a pipe of a certain length, on both sides of which a thread is cut). It is worth noting that finding the finished length is not always obtained, but below we will look at how to get out of this situation. |

| Flexible hose | You can use either a ready-made version, which can be purchased separately in a specialty store, or you can adapt any suitable hose for this purpose, its service life is much less, but as a temporary option it is quite suitable and will last at least one season. Do not forget that for mounting the hose will need special clamping clamps |

| Sealing elements | To ensure that all the connections are reliable, you should seal them with special rubber gaskets of a certain diameter, you can buy them, and you can make them out of rubber. In addition, you can use additional sealing materials - fum-tape, Unipak composition and other similar materials. |

Note! It is not recommended to purchase a ready-made version intended for use in bathrooms, as the coating on such products is poorly resistant to adverse conditions of use in the open air. Most often, the decorative coating begins to peel off after a few months of use.

Designs

We will analyze two versions of the systems - rigid and with flexible hose, they differ in the method of assembly, so a separate chapter will be devoted to each of the solutions. You just need to choose a mixer that is better suited for your operating conditions.

Fixed watering can

The order of work is as follows:

- First of all, you need to calculate what the total length of the system should be from the attachment point to the barrel to the edge of the watering can, and it is very important not to forget to take into account the fact that when fastening a part of the pipe goes inside the tank. Too large size will cause the rain to be low, and tall people will wash, bent over and constantly hitting their heads, which of course is undesirable, as comfort is significantly reduced.

Tip! If the height is not enough to position the watering can or the outlet in the tank is located on the side, then you can use one trick: weld a small ledge on the surface and position the system at an angle, this saves height and allows you to direct the flow to the middle of the shower platform.

- Next, you need to make a pipe or buy ready sgon. The production variant is relevant when the length of the element must be large and it is unlikely that it will be possible to acquire the finished structure. The works are carried out as follows: first, a pipe of the required diameter is selected, after which a piece of the required length is cut and a thread is cut from its both sides, the pitch of which must correspond to all other elements.

- The assembly is carried out in the following order: first, a sprayer is screwed in through the connecting nut or directly into the faucet, do not forget to wrap the thread with sealing material. Further, the crane joins the required length, it can be both small and very long, it all depends on the design features.

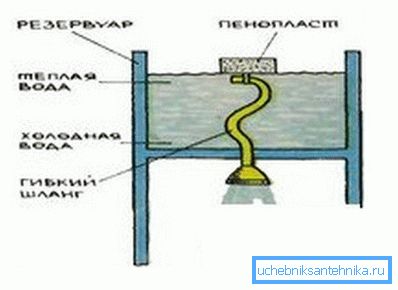

Flexible hose system

Now consider how to make a shower for yourself, if it is necessary to ensure its mobility and mobility, the work is carried out as follows:

- First of all, you need to prepare a flexible element, the length of which must be calculated in such a way that it is convenient for you to use the system. For these purposes, suitable as a ready-made version, and other improvised elements of PVC or other polymeric materials.

- For mounting, you will need special threaded adapters, but for reliability, the hose must be additionally secured with stainless steel or galvanized steel clamps.

- Next you need to make a sidebar in the tank, it can be both in the design with a hose, and rigidly fixed to the barrel. It is important that the water intake is 20-30 millimeters above the bottom level in order to prevent sediment from entering the watering can, as this is not very hygienic and causes clogging of the holes.

- Further, all the elements are interconnected, pay special attention to threaded connections, they must be well sealed to prevent any leakage.

- After assembly, be sure to check the system for leaks to know that all the nodes are securely attached. As you can see, the instruction is quite simple, and the work is almost for everyone.

Naturally, if there are any problems, then you will not have a question about how to disassemble the shower watering can for cleaning or troubleshooting. In general, if all the work was carried out carefully and from quality materials, then the durability of the system is very high - the design serves for many years without any maintenance.

Conclusion

Of course, if you do not want to engage in such work, then you can purchase a ready-made solution. But if it comes to custom designs, then there is simply no other option than assembling with your own hands.

The video in this article will help to understand the topic even better, especially if you still have any questions.