Waterproofing the pool itself

Waterproofing the pool is crucial to preserve the integrity of the structure. The material from which the design of the bowl is made is subjected to a daily load, in case of leakage, it will quickly crack. If the protective layer is destroyed, substances hazardous to human health can penetrate the water, so waterproofing the pool with your own hands should be done carefully using suitable materials.

Types of waterproofing materials

Protection of the pool structure against water is performed from the outside and the inside. External waterproofing is performed to block groundwater washing, and internal waterproofing is necessary to preserve water in the bowl. The market of waterproofing materials offers a whole list of products designed to create a protective coating for the pool and protect it from leakage. When performing work apply:

- penetrating waterproofing;

- PVC membrane;

- liquid rubber;

- polymerizing impregnations;

- liquid glass;

- roll glue waterproofing.

All materials are subject to the same requirements: water resistance, elasticity, good adhesion to the surface of the structure, safety for health, resistance to dynamic loads.

Exterior waterproofing technology

To increase the strength of the bowl during the construction phase, plasticizing components are added to the concrete. Work on the protection of the external part from moisture is performed in the following sequence:

- A trench is being dug near the walls, the outer part of the structure is being cleaned and inspected.

- In the places of concrete destruction, the jointing of cracks is performed, followed by processing with a special composition for waterproofing.

- The walls are treated with penetrating insulation, which gets into the pores of the concrete and clogs them. It is applied with a roller or spray.

- Coating and elastic insulation, such as water glass, are used. For reliability, a layer of heated bitumen-based roll material or liquid rubber is applied on top, forming a durable and elastic coating.

- Filling with clay and careful tamping is carried out.

Ways of internal waterproofing

As an internal protection of the design, film polymeric materials are used. Excellent performance, for example, has a PVC membrane. This material is environmentally friendly, serves up to 50 years, is subject to repair.

PVC waterproofing performs not only its main functions, but also serves as a decorative design of an artificial reservoir. PVC film can be with different patterns and different colors.

Using a geotextile canvas as a substrate, you can achieve smoothing irregularities and comfortable use of the pool:

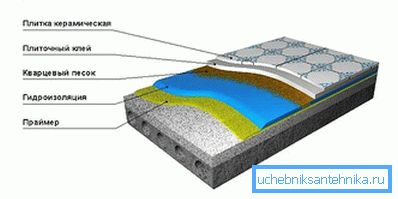

- Before making a waterproofing, the floor is poured with a concrete screed, which contains liquid glass. The walls are leveled and plastered.

- At the first stage of waterproofing the bowl, the inside is processed and sealed at the junction and entry of communications. For this, a penetrating mixture diluted with water is used. Popular mixture brand "Penetron", which is known for good quality and long service life.

- To seal the joints, it is better to use special materials - sealing tapes, cords or harnesses.

- After applying the composition, the surface is subjected to treatment with hydrochloric acid, washing and applying soda ash.

- Next, turn the coating polymer mastic. It is applied in several layers, after the first surface sprinkled with sand to enhance adhesion. Special pigments are added to the top third layer to add color. The composition applied to the walls and floor is rolled with a needle roller to remove air bubbles. The interval between applying the next layer is 6-7 hours.

- After 1–3 days, the container is filled with water for testing. In the absence of leakage, the internal surface is ready for use or finished with tiles. After its laying, the seams are rubbed with special compositions based on epoxy resin or polymer. Its excess immediately removed from the surface of the tile, because after hardening it will be impossible to do.

Waterproofing of the pool can be done with liquid rubber. This material combines the best qualities of PVC and liquid insulation:

- First, glue the reinforcing fabric on the joints, seams, the junction of the bottom to the walls. After that strips are processed by mastic.

- Then liquid rubber cover the walls and bottom of the pool. Reinforcing fabric is laid on top and liquid mastic is applied again.

- After drying, the surface is decorated with mosaic, and if color rubber was used, then finishing is not required.

Swimming pool waterproofing with its own forces is a complex of sequential processes; it is impossible to neglect the technology of applying compositions. Only careful treatment will make the bowl sealed and eliminate leakage.

Video

How to consistently equip the pool can be found by viewing the video: