Ways of drilling water wells: a review of existing variants

A person feels the need for water as much as he exists. It has long been one of the main sources of its production, albeit primitive, but wells that are now being formed using the latest technologies. Consequently, the methods of drilling wells are now much different from previous methods.

Until today, the wells have not lost their relevance, and to this day they remain indispensable attributes of private land ownership.

This is explained by the fact that in a certain plan wells are much more profitable to use on their own section, since, unlike the central water supply, they have such advantages as:

- The ability not to depend on a centralized water supply system, therefore, on its accidents.

- With the help of the well you can get to the deepest depths where the artesian water is located, which is considered to be perfectly clean and useful. In other words, the quality of drinking water is many times higher than in the water supply.

- The well allows, by choosing a certain depth, as well as selecting pumping equipment, to regulate the amount of water supplied to the house and the site as a whole.

Even before the creation of this source of water in your area, it is very important to choose the method of drilling wells. At the same time, there are a lot of factors influencing the preference of one or another method. These include various geological conditions, an indicator of the depth of the aquifers, and the choice of resource for water intake.

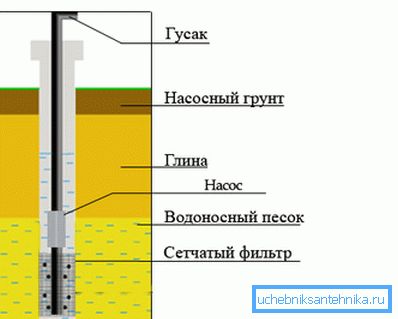

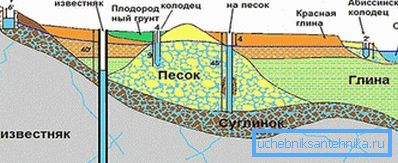

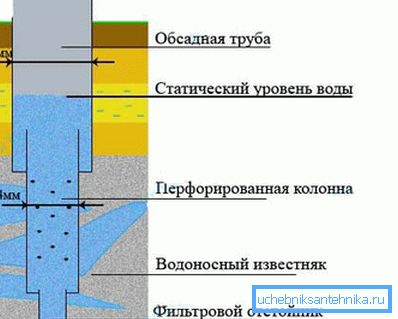

Note! The choice of the method of drilling a source for extracting water will also depend on its type and on its immediate purpose. There are two main types: filter or sandy (depth is up to 35 m, and flow rate is up to 1 cubic m / hour), deep on “limestone” or artesian (depth can reach more than 100 m, and debit makes up to 100 cubic m /hour).

The formation of wells can occur both mechanically and manually. Also, these methods are divided by their focus.

In a word, thanks to the emergence of new technologies, there is something to choose from, and now every owner of a site can easily choose for himself the best option both in terms of cost, production time, purpose, and other necessary parameters.

Note! Manual drilling method, which does not need expensive equipment, is mainly used to create wells with shallow depth. The mechanical method of drilling requires the involvement of expensive heavy equipment and special equipment. This method is used to slaughter artesian sources, as it allows you to reach the recessed aquifers.

In order not to run into a dishonest contractor, even before contacting a company that provides services for the bottom of a well, one should independently study both the methods of drilling and their features. After all, having such information, the likelihood that any unfair company will deceive the land owner by offering an inappropriate method, the price of which, by the way, will still be overstated, is practically reduced to zero.

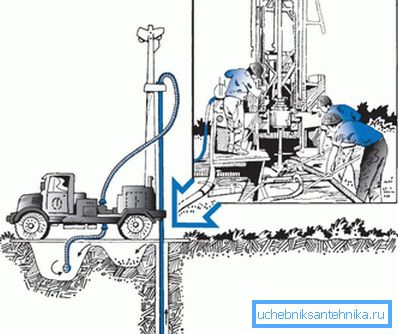

Mechanical methods for drilling aquifers

Mechanical drilling is done by using nozzles made of hard alloys. They are placed on the drill. You will also need heavy equipment.

The wells produced by this path are characterized by high productivity and excellent water quality. This category of method of drilling sources for the extraction of water in turn is divided into subtypes.

So, to mechanical methods include the following 3 main types that are used in modern engineering hydrogeology:

- mechanical rotor subtype;

- colon subtype;

- screw subtype

Features of the column method

Core drilling is considered to be a good effective option from the category of the mechanical method, in which the produced soil is an integral core called “core”. It is advisable to use this method for bottomhole drilling with a large depth indicator (up to 1000 m) in areas where the rocks predominate.

The technology of core drilling is performed by rotating a drill, which has a high-strength nozzle that looks like a diamond crown.

In addition to these advantages, this method has several important advantages:

- excellent speed of the drill;

- compactness and good maneuverability are peculiar to core drilling rigs;

- due to the fact that the destruction of the rock is not a continuous method of slaughter, and the ring method, increases the efficiency of drilling.

Note! Basically column type is used with washing. For this, the destroyed rock, located outside the core pipe, is brought to the surface either by water or by mud, which is fed under high pressure. Rinsing with the solution allows to strengthen the walls of the well in unstable soils.

The disadvantages of this method include the fact that with the help of it it is possible to make wells with only a small diameter (up to 15-16 cm). Also, when they are formed in this way, the wear of the drill bits occurs fairly quickly.

Note! The cost of the well, which is planned to be created using the core method (the cost of penetration of 1 mc varies in the range of 400 to 600 rubles), will directly depend on the bottomhole depth and complexity of the rock in the area.

Features of the mechanical rotary method

The technology of rotary drilling of wells includes the use of a bit, which is attached to a drilling rig capable of performing rotation. He, in turn, is driven by a specially built device called the "rotor".

This method of drilling is considered to be one of the most productive, as it allows to reach deep aquifers, where the purest water is located without various compounds, including iron. Also, drilling in a rotary way allows to achieve a high stable flow rate of the source on virtually any soil.

Perhaps the disadvantages of this method include the high consumption of clay and water, which are necessary for the manufacture of the washing mixture, as well as the fact that with the very washing of the trunk itself, clay elements enter the aquifer. All this, of course, makes this method of forming a well more laborious.

In addition, in winter there are certain difficulties when choosing this method. This is explained by the fact that in this case it will be necessary to heat the washing mixture, what to do in such volumes is not at all easy.

Note! When wells are formed by a mechanical rotor method, the price of penetration of 1 m will be approximately 2 thousand rubles.

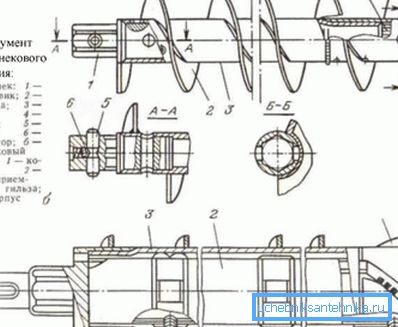

Features auger method

Such a method is considered to be the most optimal for creating shallow sources in areas where loose soils are located. With the use of auger drilling option, work on the formation of a well for the production of drinking water are carried out fairly quickly.

Moreover, this method does not require hiring highly skilled workers and the use of heavy special equipment. That is why it is often chosen to create aquifers in private land ownership.

All work with this type of drilling is performed using a screw. This device is a rod with blades and cutters. With the help of these elements, the rocks are removed from the well channel.

The screw method has the following additional advantages:

- ensuring high mechanical speed;

- in the process of work, the cleaning of the bottom of a well occurs continuously, that is, parallel to the process of rock destruction

- it is possible, simultaneously with drilling, to make and lay the walls of a well from concrete or steel, which are necessary to hold the rock in order to prevent its collapse.

Manual Aquifer Drilling Techniques

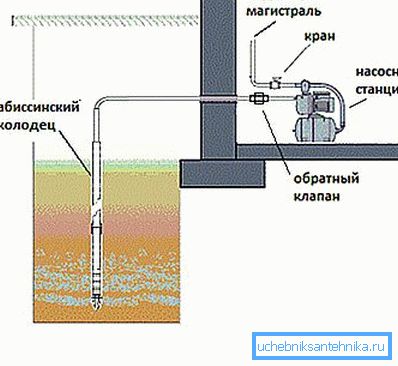

Features of the Abyssinian method

This method of forming a water source is the simplest of all. Its technology consists in the sinking into the ground of a rod of steel with a sharply sharpened tip. The diameter of this device, as a rule, does not exceed 3-4 cm, so this method is popularly called “needle drilling”.

Along with such advantages as the possibility of drilling this type of well with your own hands, as well as the use of holes in the core as a casing, the Abyssinian method has many of the following disadvantages:

- Limited well depth. This indicator should not exceed 7-8 m.

- In the case when it is not known exactly where in the area the water is located, it is possible to “riddle” its entire area with the holes, while still not achieving the desired result.

- The small diameter of such a well does not allow the use of a submersible pump, which is why the only option is to use a surface device that is not able to provide good pressure in the water supply system at home.

Features of the shock-cable method

Shock-rope method is quite popular both among small companies involved in the bottom of wells, and among private landowners, since it is possible to carry out this measure with the help of the simplest technology. To do this, you need a winch, tripod, and a drive-in "glass" with a sharp edge, which should look like a hollow tube.

The technology of creating a well by this method consists in suspending the pipe (cup) by means of a cable to the tripod and in sharply lowering it and raising it with a winch. In this case, the pipe will be clogged with earth from the canal, therefore, the “glass” will periodically need to be cleaned.

Such drilling is effective in the case when the site is soft and viscous soil. If it is dry and free-flowing, the soil will not be able to linger in the “glass”, therefore, instead of it, it is more expedient to use a shell that can capture the earth from the wellhead, and then deliver it to the surface.

As it became clear, this type of drilling is time consuming and protracted. However, with the help of it, it is possible to create a fairly high-quality channel for a well, of course, provided that the process instruction is followed.

Features of the manual rotary method

Manual rotary drilling of wells also refers to simple methods, since in this case a normal auger in the form of a huge drill is used to form a channel. Unlike the mechanical rotary method, the auger in this case is driven not by a special mechanism, but by human effort. This type of drilling is effective in creating wells in areas with loamy and gravel soils.

When a loose soil is present on it, the well is blocked by this method with the use of a drill-spoon. This device consists of a cylinder with spiral holes. It should be noted that this method is a time consuming and lengthy exercise.

Aquifer Drilling Techniques

Well drilling methods differ not only in the nature of soil destruction and in the use of various devices. They are also subdivided by orientation.

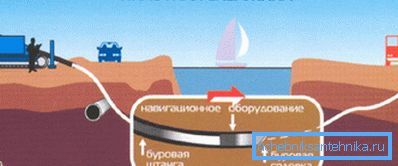

So, there is a drilling of horizontal and directional wells (HDD and BF). Such methods include all options for the formation of wells, the trunks of which have, even if small, deviations from the vertical.

Moreover, in some cases, oblique drilling is the only way to achieve the task.

For example, such methods for creating wells will be relevant in the following conditions:

- on the pools;

- in rocks;

- in the forest park zone;

- in densely built up areas;

- in areas where drilling is required under the road;

- in places where high-voltage power lines and other highways are laid.

In addition, such methods allow you to create additional channels in an existing well, as well as to lay underground communications without using trenches. The most popular method of trenchless construction are pilot wells, the formation of which is carried out using a drilling head with a built-in radiator, with the existing bevel in the front.

Since horizontal and directional wells are formed with the use of special equipment only by qualified specialists, therefore, these methods are very expensive, therefore, in private land tenure, HDD and TFA are used quite rarely. The exceptions are cases when it is impossible to do without these methods.

Note! HDD and NCB require accurate calculations, so if downhole is required by just one of these options, you should contact only verified contractors.

Conclusion

Of course, manual methods of well formation are the most economical, however, it should be noted that, using modern methods of mechanization, it is possible to drill deep sources, which will allow to obtain higher quality water and achieve a good flow rate for several decades. The video in this article will help you to understand in more detail this important question for many landowners.