We choose and install the valve mom-mom, mom-dad and other

In this article we will talk about what a mom-dad crane is and how it differs from similar devices with other types of connecting elements. In addition, we consider the classification of cranes in accordance with the type of connection, as well as learn about the features of operation of these devices.

Classification of quick-fitting threaded connections

You do not know how the tap 1 2 dad dad differs from the similar device mom-mom? In order to give an exhaustive answer to this question, we consider the features of threaded connections used in the assembly of pipeline systems.

In order to connect the pipe to the fitting, it is necessary that, on the one hand, the fitting be the connecting element and, on the other hand, the coupling. Thus, the fitting is screwed into the coupling, as a result of which the required fixing strength is achieved.

Of course, in order for the described method of fastening to be applied in real conditions, the coupling element in the form of a coupling must be equipped with an internal thread, and the fitting must be external.

Traditionally, "mom" is called the connecting element, made in the form of a union coupling. Thus, the "father" is a connecting element, made in the form of a choke.

Important: Wiring diagrams that work with the use of “mom” and “dad” are commonly used in the construction of pipelines of small and medium cross-sectional diameters. Installation of large pipeline systems with a cross-section diameter of more than 50 mm is usually performed using a stronger flange or welded joint.

So, we decided on the main types of threaded connections used in the construction of pipelines, back to the consideration of valves.

Threaded connectors on valves

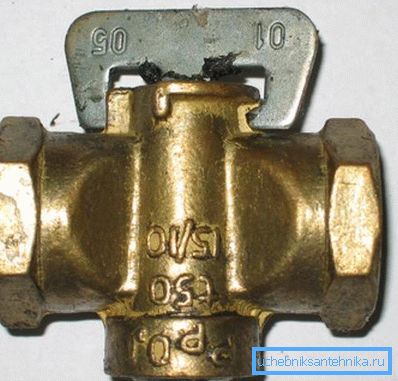

- Crane 1 2 mom dad, what characterizes its design?

On the device body, in addition to the rod with the flywheel, we can see two nozzles located on the same axis. On the one hand, the nozzle ends with a female threaded coupling, the diameter of which is 1/2 (12.7 mm).

On the other hand, the pipe ends with a male threaded nozzle.

- The mother-mother valves on both sides are equipped with nozzles that terminate in couplings. Such devices are the best solution for the installation of a crane in the pipeline rupture.

- Devices with a connecting element of the "father-father" type are sanitary fittings, on both sides of which there are fittings with external threads.

Important: In all the listed devices, the case and the connecting elements are made of brass or stainless steel AISI 316L. Acquisition of valves from ferrous metals or light alloys with the addition of aluminum is not recommended.

Application features

A modern ball valve is used to build pipelines designed for transporting liquid and gaseous media. That is why it is possible to find devices for sale, with coupling-type connecting elements, designed for working with gas or for working with water.

So, how do gas modifications differ from water ones, except in the color of pens?

- Gas stop valves are manufactured taking into account the security requirements of gas supply. Compliance with these requirements affects the quality of the materials used and the accuracy of assembly of all structural elements.

Again, all officially manufactured valves for gas distribution networks are subject to mandatory quality control and then certified for use in the territory of the Russian Federation and the CIS countries.

Valves for gas are distinguished by the following characteristics:

- All structural components, including the stem, are assembled inside the case, as a result of which the device is absolutely leak-proof and non-separable.

- The presence of an anti-explosion rod makes operation safe in both domestic and industrial environments.

- The presence of technological devices designed to block and seal the flywheel.

- The ability to operate devices in a wide range of temperatures (from -40 ° C to + 60 ° C), which is more than relevant when operating in domestic climatic conditions.

- The ability to use devices in a wide range of pressure indicators (taps are designed for a nominal pressure of up to 5 Bar and a maximum of up to 20 Bar).

- Ball valves for water are made with a smaller number of requirements for the quality of the finished result.

The only essential requirement that the finished product must meet is a combination of tightness and high corrosion resistance.

Externally, ball valves for water do not differ much from similar devices designed to work with natural gas. But there is one important point: if the gas faucet can be put on the water supply system, then water shut-off valves can not be used to work with gas!

Features of the installation of gas valves

Until recently, natural gas supply to homes or apartments was controlled by mother-to-mother cork taps. Such devices were wound on external threads in the pipeline rupture.

To ensure the required tightness, the threaded joint was rolled through with tow, and later with a fum tape. In order to prolong the life of the connection, the gap along the contour of the fittings in the coupling was painted over with oil paint, which, after drying, eliminated the possibility of leaks.

Today, primitive and non-durable cork cranes have been replaced by more advanced ball modifications with a large resource.

New devices, like the old versions, are equipped with connecting elements of the "mother-mother" type. This is done for ease of installation in the pipeline rupture without the need for additional transition fittings, which can adversely affect the degree of tightness of the structure.

Important: At construction of gas distribution networks only special certified locking equipment is used. That is, buying a valve for gas, do not forget to make sure the certificate is available.

Replacement of the locking equipment is carried out by specialists with special tolerances. Independent installation is, first of all, potentially dangerous, and in addition, it may result in penalties.

Features of the installation of plumbing valves

The installation of a ball valve on metal pipes can be done by hand without the need to hire specialists.

Instruction of work is as follows:

- If you need to install a device such as "mother-mother", we cut the pipeline, having previously turned off the water supply. Cut a piece of pipe the size of the body of the crane, not counting the side pipes.

- We process the ends of the pipes with a grinder, cleaning burrs. Then we remove the outer chamfer, which will simplify the process of threading.

- Next, prepare the cutter (die) and insert a cutter into it, corresponding to the size of the tap thread.

- The end of the pipe is lubricated with a thin layer of grease, for example, you can use lithol. Apply the same lubricant to the cutter.

- We apply the cutter to the end of the pipe and with a certain effort we begin to cut the threads strictly clockwise. Cut about 6-7 turns.

The crane on the iron pipe must be wound for at least 5 turns. Today on the market you can buy devices with a cap nut, designed for 3 turns, you should not buy such reinforcement, as it is designed for brass and copper pipes.

Important: If after several turns the plate goes tight, we go back one turn and thus cut the chips. After that, you can move forward again.

- We clean metal sawdust from the finished thread and wind flax or fum tape.

Winding is performed in the direction of winding the crane. If you shake in the opposite direction, the twisted coupling will assemble the seal into a clump.

- We harvest the crane on the prepared ends of the pipes previously removed from the brackets. Grabbing with a spanner wrench, we wind the valves, until 4-4.5 turns are made from each end. Make sure that the flywheel of the device gets into the thawed position, where it will just turn.

Polymer varieties of valves of the type "mother-mother"

In addition to the previously listed metal devices with coupling connectors on the nozzles, stop valves made of polymeric materials are commonly used. A typical example is polypropylene taps intended for installation in plumbing systems.

Such devices are equipped at both ends with couplings into which the ends of the pipes are inserted during the soldering process. Water fittings made of polypropylene, as well as analogs made of metal, are selected in accordance with the diameter of the inlets, measured in inches. However, the price of polymer products is more affordable than the cost of metal products.

Almost all polypropylene cranes on the market are ball-type devices with mother-to-mother connecting elements.

Conclusion

Now that we have learned what types of connections are used on valves and how some types of valves differ from others, it’s time to put this knowledge into practice.

Do you have any questions for which you did not receive any interesting answers? More useful information can be found by watching the video in this article.