We do plumbing in a private house

If you decide to make plumbing in a private house with or without a storage tank, it means that you have the opportunity to use a well or a well (artesian or sand) for this purpose. For pumping water in such cases, surface (hydrophores) and submersible (deep) pumps are used, but the second option is more advantageous in terms of technical parameters.

Therefore, we will deal with the installation of the submersible pump and the wiring of polypropylene pipes, and in addition, we will show you the video in this article.

Autonomous water supply

Recommendation. Submersible pumps are vibratory and centrifugal, but the water supply system in a private house will be better with a centrifugal unit. The fact is that vibration pumps are cheaper, but their technical characteristics are also lower. In addition, vibratory water intake causes well-inflating, which leads to a decrease in flow rate.

Well flow rate

- In order for you to know that your water source (well or well) will be sufficient for the needs of the farm, you need to determine its flow rate, which is measured in m3/ sec, m3/ min, m3/ hour and m3/day. That is, you need to determine how fast the source will be replenished at the water intake.

- For this, it is necessary to pump out all the water from the well (well) and measure the time spent on it (it is good to use the pump for these purposes). Now calculate the volume of pumped water - this can be done using a long tape measure or cord - measure the distance from the static level to the surface of the earth, and the distance from the surface to the bottom - the difference between them will be the height of the water column.

- In addition to the static, you need to determine the static level - it is determined when the water intake is made, the static level is lowered and, finally, installed in one place - this will be the dynamic level (for pumps of different power, this figure will differ).

- The debit is determined by the formula: Dt = V / (Hdin-Hstat) * Hw. Here Dt is the desired flow rate in m.3/ hour, V is the pumping speed in m3/ hour, Hdin - dynamic level, Hstat - static level, Hw - height of the water column from the bottom to the static label.

- The power of the submersible pump should not exceed the flow rate of the source, and you can get the figure you need if you sum up all water intake nodes in the house and on the site. For simplicity, you can focus on the table below, through which you can make a project of water supply in a private house.

| Bathroom name | Water flow |

| Washbasin taps | 0.4m3/hour |

| Bidet | 0.4m3/hour |

| Toilet | 0.4m3/hour |

| Sink taps | 0.7m3/hour |

| Dishwasher | 0.7m3/hour |

| Washing machine | 0.7m3/hour |

| Shower cabin | 0.7m3/hour |

| Hydrant for watering the garden (garden) | 0.7m3/hour |

| Bath | 1.1m3/hour |

Approximate water consumption for different bathrooms

Excavation

To figure out how to get a water supply system in a private house, you need to know the depth of soil freezing in your area - the trench depth will depend on this indicator - it is best to do it 50 cm below this critical point.

In addition, the bottom of the trenches must be filled with a layer of sand at least 2-3 cm high - this measure serves as protection for the polyethylene pipe from its damage with various sharp objects that may be in the ground (glass, stones, wire). When filling the pipe and cable, they also first pour sand, and then throw in the ground.

Recommendation. In order to tamp sand poured into a trench, it is not at all necessary to use a tamper. It is plentiful enough to be poured with water, and it will immediately drain

In addition to the trench, you will have to dig pits against the wall from the inside and outside in order to be able to start a polyethylene pipe through or under the foundation.

If you have a monolithic foundation, then in the ribbon there is necessarily an armature that will not allow you to use a diamond or pokite cutter - the hole will have to be hollowed out with a chisel and drill and the armature to be cut with a grinder. However, you might as well pass under the foundation, but for this, the outer and inner pit must be made sufficiently deep.

If you have a well, then you will need to drill a hole in the well ring, but the instruction provides for their manufacture with a wire or reinforcing cage, therefore, you cannot use a core mill.

The most convenient way to do this is with a drill - draw a circle of the desired diameter and drill a hole along the perimeter with the minimum distance between the holes, as in the top photo. After that, a piece of concrete can be knocked out with a hammer or a chisel and a hammer drill can be used for this.

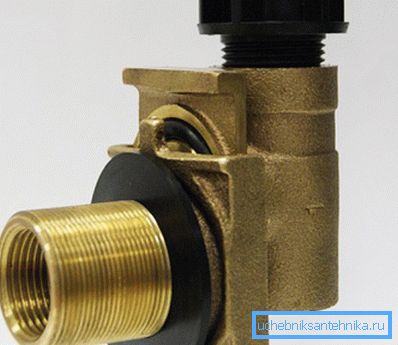

Adapter use

In those cases, if the wiring in the private house is done from the well, then a borehole adapter can be used - this device performs the same role as the compression corner fitting, although its price is somewhat higher. It is mounted below the ground freezing level, and we will now tell you how to do this.

As a rule, the production and casing pipe when drilling a well is obtained higher than required, therefore, the excess part is simply cut off by the grinder, after which the tip is set. But we will still have an adapter - a hole for it is drilled with a diamond crown cutter of a suitable diameter.

To install and fix a part of the adapter with a pipe on the pipe, you will need to screw the rod into its other half - there is a special threaded hole for this. A polyethylene pipe (HDPE) with a direct compression fitting at the end can be used as a rod - the thread just fits. Just be careful that the adapter is not arbitrarily disconnected and does not fall into the well.

Lower the adapter to the level of the hole and, helping with your fingers from the outside, pull the nozzle and twist the nut on it to fix it - after that the parts can be separated.

Now the check valve is screwed onto the submersible pump so that the water does not flow down under pressure, and we screw the HDPE pipe (low-pressure polyethylene) of the desired length using a compression fitting - the pump should dive below the dynamic level by at least 30 cm. On the other The side of the HDPE is also wound on a fitting that connects the 32mm pipe with the removable part of the adapter.

Now you have to do it yourself, with the help of a rod, lower the pump into the well and put the removable part on the previously fixed part - a special lubricant will not allow water to seep at the joint. It will not be possible to use the well adapter for the well, since the concrete rings are too thick walls and there is not enough length of the pipe for installation.

Pipe laying and pumping station assembly

As mentioned earlier, the supply of water to a private house, we will make a 32-mm low-pressure polyethylene pipe. To do this, fasten a straight fitting to the adapter or, if there is no one, make the connection with a compression corner - you can see it in the upper photo.

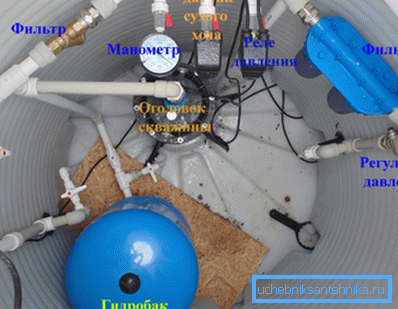

The pipe must be pulled from the well to the house - to the place where the pumping station will be installed - most often for this purpose they dig a hole in the floor, lay it over with brick masonry and concrete.

We now turn to the assembly of the pumping station - if you doubt the depth of the gasket, you should think about how to warm the water supply if it froze. In such cases, right after the polyethylene pipe, a metal tee is inserted into it to enter the heating cable, as shown in the top photo. In front of the tee, you can install a ball valve - with it you can drain all the water from the system.

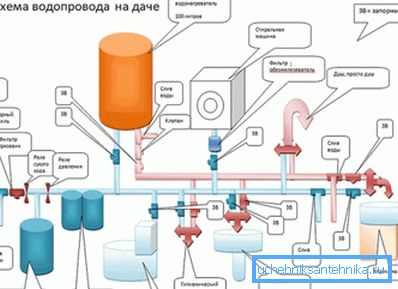

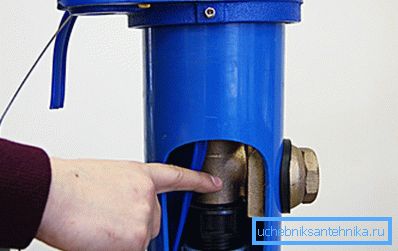

After the tee is mounted trunk valve, and then the coarse filter. After the filter, a block is installed with a pressure switch and a dry-running sensor, but it would be better if you purchase these devices separately from each other — then if you fail any of them, you will no longer need to change the entire unit.

At the same site, you will need to install a membrane tank - with its help, the system creates pressure and water supply, and after all this, do not forget to put a fine filter in front of the water-folding unit (usually such devices are made with cartridges).

The pump is connected to the network using a cable - if it is a well, then there are special connecting terminals on the tip, as well as a special bolt for fastening the cable on which the pump is suspended. If you have a well, then the cable is passed through a hole in the concrete ring, and the cable is spliced to another piece with the help of twists and thermal nozzles.

Note. After assembling the pumping station, you need to make a test start of the pump and check all connections. If you find no leakage anywhere, then cement the cement mortar or tile glue into the passages in the foundation or in the ring of the well, at the point of the pipe passage. Fill the pipe and cable with sand, fill it with water for shrinkage, and throw a trench in the soil.

Polypropylene wiring

The joints of polypropylene pipes, which are now most often used for wiring, are carried out with the help of a special soldering iron and nozzles, which are selected to their diameter. Polypropylene fittings such as tees, couplings, angles of 32 ?, 45? and 90 ?, as well as fittings with external or internal thread on one side and PPR taps.

In addition, the cost of plumbing in a private house, made of polypropylene pipes, is much lower than a similar device made of metal or metal-based laminate.

| Diameter in mm | Solder depth in mm | Heating time in seconds. | Cooling time in min. |

| 20 | 14–17 | 6 | 2 |

| 25 | 15–19 | 7 | 2 |

| 32 | 16–22 | eight | four |

| 40 | 18-24 | 12 | four |

| 50 | 20–27 | 18 | four |

| 63 | 24–30 | 24 | 6 |

| 75 | 26–32 | thirty | 6 |

| 90 | 29–35 | 40 | eight |

Table of welding parameters of SPR pipes

When welding pipes for plumbing in a private house, do not overheat or push the fitting hole further than necessary, as this will lead to blockages - polypropylene will flatten out and block the channel. In order for the soldering to turn out to be correct, as in photo No. 4, you need to withstand the time of heating and cooling of the flow tube, and also observe the dimensions of the pipe entry into the fitting — you can see these parameters in the table above.

For ease of installation, it will be much easier for you if the soldering work will be performed in blocks, but for this you need an assistant, otherwise, how to lay the assembled block or long pipe. Your partner will only have to hold the pipe or the welded section in the desired position so that the fixation will be even. PPR pipes are attached with brackets or plastered with strobes.

Conclusion

In conclusion, I would like to say that the autonomous water supply system in a private house directly depends on the operation of the pump and this is influenced by the number of cycles of its starts and stops. By factory default, it stops at a pressure of 3 atmospheres, and starts at 2 atmospheres. But you can change the settings on the pressure switch by setting them to 5 and 1.5 atmospheres, respectively.