We equip the filter for the well independently

If you dug a well, and having reached the aquifer, you found that the quality of the water leaves much to be desired, do not worry. And you certainly shouldn't be in a hurry with installing expensive, superficial filter systems. In the overwhelming majority of cases, the bottom filter for a well - made with your own hands, radically changes the situation. Instructions for the arrangement is available for almost any person, we will talk about it now.

When you need a filter

The system of water purification in a natural source is not always necessary. It all depends on the type and condition of the rock in the aquifer at the bottom of the well. Also important is the location and power of the aquifer.

It is determined in the process of digging a well or drilling a well. In older designs, during the cleaning of the barrel.

Filters for a well can be equipped differently.

- If the springs beat from a sufficiently dense clay layer, the bottom of the well does not dissolve and the water column in it is more than 1 m. So in this case, you can do without filtering at all.

- With a height of water column of 50 - 70 cm on dense clay, you can, at most, make dumping with large rubble or pebbles in a layer of 100 - 150 mm. The fine fraction of the dumping in this case is not recommended because it is possible to cut off the aquifer. Also, water carriers, pierced in solid shale or rock, do not need filters at all.

- If the aquifer is in a non-greasy, soft clay and at the same time the power of the spring is large enough, in the near-bottom area the water will be constantly turbid. With a large amount of water, you can of course do without a filter, but still it is better to make dumping with large rubble 150-200 mm so that the bottom of the well is less eroded.

- If the trunk is on a false swimmill, that is, the bottom consists of sand dust and there are no powerful springs as such, plus water comes slowly and evenly, then such a bottom necessarily requires the equipment of a full-fledged filter.

- Otherwise, any attempt to get water, the suspension from the bottom will rise. Moreover, the pump, especially the vibration type, will be impossible to use, as it will constantly be clogged and, eventually, will fail.

Important: to improve the quality of water and as an antiseptic it is recommended to put silver in water. It is not at all necessary to use expensive rocks containing silver, it is enough to put a few small silver things, coins or dishes.

What to look for

Material selection

- Quartz sand with coarse grain, fraction with a section up to 1 mm. As a rule, there is a lot of it along the banks of rivers. Light translucent material with small dark patches. Since the grain fraction is small, it is difficult to rinse it under running water. It is better to collect at the bottom of the tank, fill with water and shake. After 20 - 30 seconds to drain the water, so until such time as the water is clear.

- River pebbles - fine natural material of a mixed fraction, having a rounded shape which is also found along the banks of reservoirs. It is much easier to wash it, it can be done with the help of a tray in the same reservoir or with the pressure of water.

- Gravel, is a loose sedimentary material having a porous structure. The fraction of gravel ranges from very small, a few millimeters, to a rather large 2 to 3 cm. It is widely used in filtering systems, but it is absolutely impossible to fall asleep in your well gravel, as it accumulates pollution.

- Rubble - rock, as a rule, a large fraction.

But when choosing rubble one should be very careful, not every type of rubble is suitable for such use.

- Limestone crushed stone common in construction gives a lot of dust and will pollute the water. Plus, with a long stay in the water, it can dissolve.

- Crushed granite is not suitable, as it has an increased radioactive background.

- We are suitable crushed stone from neutral minerals, for example, from jadeite. If you are not a geologist, we do not advise you to look for it in nature, the simplest and most reasonable is to buy it in a specialized store of bath products. It is used in the steam room stove.

- Shungite, This mineral is also called petrified oil. It is widely used in industrial filters for water purification from heavy metals, organics and petrochemicals. If your well is in the city or not far from the busy highway, then filters for wells with schungite will significantly reduce the likelihood of water pollution.

Tip: we do not recommend to use for dumping minerals that have passed through industrial crushing, as they may be contaminated from crushing machines. If there is no way out, the longer you rinse the stone before laying, the better.

Types of filters

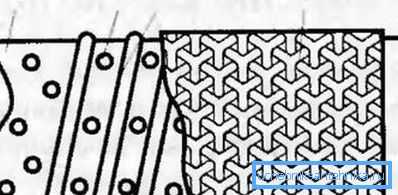

- The direct filter is placed from the bottom up, from the large fraction to the smaller one. Apply when the bottom consists of loose, not greasy clay or to protect against quicksand.

- Reverse filter - here the system is opposite, a smaller fraction initially fits to the bottom and then there is a tendency to increase the grain. Used on a sandy aquifer, with a calm flow of water.

- Shield for the well - used on quicksand to filter and strengthen the bottom.

The shield on the filter in the well is made according to the diameter of the well and can be wooden or stainless steel.

- A wooden shield is made of oak, beech or ash. The boards are knocked down with a gap of about 5 mm and then holes are cut to 10 mm in a checkerboard pattern on the area of the shield. After that, it turns into geotextile and sinks to the bottom. In order for the shield not to pop up, heavy stones are placed on it and a direct filter is mounted in the well.

- Metal membranes can be made of solid stainless steel sheet with a thickness of 3 mm and having a perforation of 10 mm in cross section. Or 2 - 3 mesh membranes, with a section of a link in 2 mm, also from stainless steel.

Important: Oak shield is most durable, it can last up to 50 years, but only oak oak is suitable. To do this, it must be soaked in running water for 1–3 years. Otherwise, the water at the source will be bitter for several years.

Straight filter for loose clay bottom

- The purpose of the design in this case is not so much to purify the water, as to strengthen the bottom of the barrel. Originally removed silt. After that, crushed stone of large size is laid.

- The second layer is crushed stone or pebbles with a section of 5 - 7 times less than in the first layer. From above the small river pebble or shungit is laid out. On average, each layer has a thickness of about 150 mm.

Sand bottom filter

This design not only blocks the raising of sand dust up, but also protects the bottom from large debris. Initially, a layer of quartz sand is laid, shungite, gravel or river pebbles are poured onto it.

From above lay rubble section of the order of 50 mm. Since making a filter in a well with a design height of about half a meter does not always allow the height of the water column, make sure that it is at least 35 cm.

Abyssinian well

- In most regions of our vast country, a simpler method of extracting water from the subsoil is used. The fact is that to dig and equip a full-fledged well costs decent money. The price of the Abyssinian well is negligible compared to its mine counterpart.

- The design of such a well is extremely simple, and there is enough water in it to meet the needs of a summer house or a small house. Initially, a well is drilled to a depth of 20 m using a conventional auger or fishing ice ax.

- When the drill opens the roof of the aquifer, it is pulled out and the column is started, at the end of which there is a steel, sharp tip “needle”, immediately followed by a tubular, perforated filter and the casing itself. It is possible to drill and equip the whole structure in 1 - 2 days.

- The most important component parts are the filter and the pump. Making a filter for the Abyssinian well is simply elementary. To do this, take a stainless pipe, of suitable diameter and a length of from 0.5 to 1.5 m, perforation is applied to it in a staggered manner using a grinder. The perforation area must be longer than 25% of the total pipe area.

- Then it turns into a fine stainless steel mesh and is soldered with tin or welded by spot welding. It is possible to use stainless wire instead of a net by winding it with a gap of 1 mm around the pipe, the ends of the wire soldered or fastened with clamps.

- For these purposes, you can also use a PVC-U pipe, but in this case, so that the plastic is not deformed when the column is driven, a steel rod is started from inside. Which connects the tip of the needle to the casing, and he takes the main load when diving.

- In the video in this article, you can observe the process of drilling the Abyssinian well.

Pump selection

- This part of the system is selected depending on the volume of water and purpose. Household submersible devices such as "trickle" or "baby" are suitable only for short-term watering of the garden. Since they are of vibratory type, they can lift sludge from the bottom and can become clogged from it.

- The most commonly used self-priming pump for a well with a filter. The price for it, of course, is somewhat higher than the “kid”, but it is more reliable and able to work in the autonomous water supply system at home.

- A well pump for a well with a filter can also be used, but it is designed to lift water from great depths, so the price is the highest. If you have great financial opportunities, you can install it.

Conclusion

In conclusion, I would like to note that even if you completely correctly and correctly equipped the filter for the well with your own hands, putting a new well into operation can last from 3 to 6 months. This is due to the shrinking process of the filter and the exchange of water.

The video in this article shows the nuances of filtering and arranging the well.