We install submersible pumping stations for the well

In terms of their design, a pumping station with a submersible pump for a well is no different from a similar installation for a well, but here there is one important advantage - the diameter of the unit does not matter! Although water sources do not differ much from each other (unless by section and sometimes - depth), special attention should be paid to this arrangement - there are some nuances.

Below we will talk about this in more detail, and also see the thematic video in this article as a supplement.

Arrangement and installation

Types of pumps

Note. According to the principle of internal device, all submersible pumps can be divided into centrifugal and vibration. And if we talk about types, here we can say about well, well, drainage and faecal aggregates, but, in fact, everything can be used for water intake from the well.

- The simplest option for water supply from a well at home is the Vibrating Pump - its power is quite enough for a family of 3-4 people and even watering the kitchen garden, besides, it has a small price and an excellent operating resource. But such a unit does not have an automatic time switch for starting and stopping, therefore a tank in the attic is needed, which is filled and then consumed until the next refill.

- In cases when the well is being drilled on sand, it may happen that the filter zone weakens (the mesh filter simply wears out) or it does not exist at all, then there are many abrasive elements in the water, that is, sand. For such situations, auger aggregates are ideal, for which grains of sand are not a hindrance.

- Drainage units can also serve as submersible pumping stations for wells, the fact is that their main purpose is pumping dirty water from different tanks, so it can be done not only water intake, but also cleaning. Such devices can be divided into three categories - with 1) multichannel, 2) single-channel and 3) open impeller:

- The multichannel wheel is used for ordinary, clean or dirty water with small debris;

- Single-channel can already be used in the presence of larger debris and even faeces;

- An open wheel type can recycle large debris, and even fallen leaves, as there is a chopper in the pump.

- Fecal pumps, in fact, also belong to the drainage, only they usually come with an open wheel type and a grinder. But these units without any problems, you can pump the water from their well.

- Most often, centrifugal borehole pumps of small diameter are used for wells, perhaps because they are more accustomed to them, but their performance is also at altitude, and the power can always be chosen sufficiently. A clear advantage here is their small diameter - the pump will not have to be pulled out while cleaning the well - it will not interfere.

- Hydrophore belongs to the surface pumping stations and is designed to supply water for domestic needs of a family of 4-5 people. If you have a watering hydrant, then the power of such a unit may not be enough, moreover, the instruction allows it to be used only up to 9 m of immersion of the water intake hose, below the station level. This means that up to the water mirror in the well should be no more than 8m at a dynamic level.

| Bathroom name | Water flow |

| Washbasin taps | 0.4m3/hour |

| Bidet | 0.4m3/hour |

| Toilet | 0.4m3/hour |

| Sink taps | 0.7m3/hour |

| Dishwasher | 0.7m3/hour |

| Washing machine | 0.7m3/hour |

| Shower cabin | 0.7m3/hour |

| Hydrant for watering the garden (garden) | 0.7m3/hour |

| Bath | 1.1m3/hour |

Table of average water consumption

Note. Pump selection should be made in accordance with the water consumption. So, you need to take into account its ratio to the power per hour consumption, and you need to take into account all the bathrooms at the same time.

Assembly work

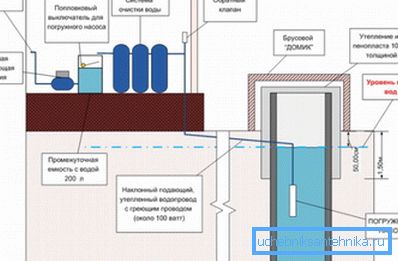

As a rule, installation begins with digging a trench from the well to the house, as in the photo above, and its depth should be greater than the freezing point of the soil of this region, at least 10-15 cm, but even better. You should also make an inlet in the foundation of the building or dig under it (this is rare) for driving the water main and electrical connection cable.

It is best to dig a trench at home from a well, but it should be noted that violation of this principle will not be a critical error for the installation of a submersible pump (but not a hydrophore).

In the wall of the well, that is, in the concrete circle, you need to make a hole through which the hose with a diameter of 32 mm and an electrical cable will freely pass. But here it should be borne in mind that not the hose itself will pass through the ring, but the corner connecting fitting, which has 50 mm. So you need to make a hole about 70 mm or 100 mm in diameter.

At a depth below the freezing point of the soil, it is very often possible to stumble upon groundwater that will penetrate through the holes made in the foundation and the wall of the well. Therefore, after laying the pipe and the electrical cable, the holes must be tightly sealed with a cement-sand mortar or tile glue of any brand.

Recommendation. The soil with which you will fill up the trench will not immediately settle into its original position, besides, there may be sharp stones that will damage the walls of the hose. Therefore, a sand cushion is poured at the bottom of the trench, a pipe and a cable are laid on it, and then another 10-15 cm of sand is poured from above. To quickly settle the sand, it must be poured abundantly with water.

It is very important to pay attention to the depth of immersion of the pump, taking into account the dynamic (not statistical!) Level of the water column. This suggests that the upper part of the unit should be lowered to a depth of one meter, and its lower part should not reach the bottom, at least half a meter.

Otherwise (if these conditions are not feasible) such equipment cannot be installed, but here you can get by using a vibration pump like the Kid or a hydrophore - the performance is not the same, but still water intake will be provided.

As a rule, a submersible pumping station for a well has a short electrical cable, which is never enough to reach the power source, that is, to bring it into the house. Therefore, you will definitely have to build it up, and if there is a terminal block on the wellhead where the connection can be made, then you will not have such an opportunity.

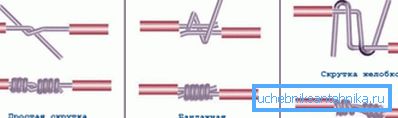

Select the missing cable with double insulation over the cross section that coincides with the pumping piece, and make one of the types of twists indicated in the figure above.

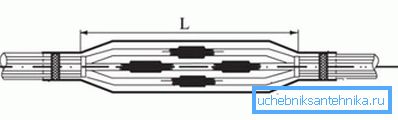

Each twist separately, and then the entire cable, in general, is closed with shrink polyolefin (POF) couplings. Such heat shrinkage when heated to 120? shrinks in size 2-4 times and after cooling forms excellent insulation, which is not afraid of water and has high mechanical strength. To heat the coupling, you can use any torch or even use a torch (a newspaper rolled into a tube).

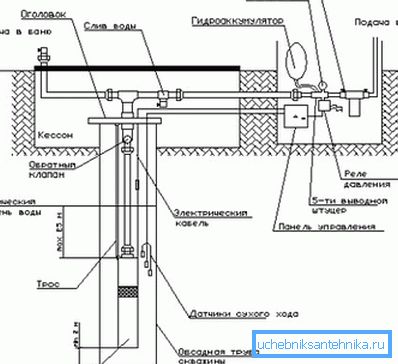

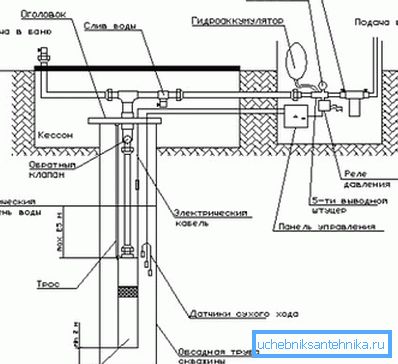

Now we come to the most basic - the assembly of the wiring diagram, which you see in the image above, and in the set of documents of the unit it is usually also supplied. But besides the order of assembly, there are still some nuances that need to be paid attention to in order to increase the lifetime of the entire station.

Let's start with the immersion and fixation of the pump - the level of burial is known to you and the hose should go without much tension, but also not to dangle. This condition is regulated by a steel cable, which is fixed at one end on the body with an eyebolt, and at the other end upwards, either to the box or to the outer ring of the production and casing pipe.

Now let's turn our attention to automation - when assembling a station, you will encounter devices such as a pressure switch and a dry-running sensor, which can be sold separately, but can be combined as one device. There is no particular difference here, but most of the masters prefer a separate version, as the more reliable one, and at a price it turns out more profitable.

Note. The reserve water tank creates a certain pressure in the system, and the larger this reservoir, the less often the engine will be started and stopped, which will increase its service life. For a residential house, a tank of 80-100 l will be enough.

The factory settings of the pressure switch are usually adjusted so that the start of the pumping engine is carried out at 2 atmospheres, and the stop at 3 atmospheres. This is quite a normal break and with a large tank of water, the start and stop modes will be made fairly moderately, but you can reduce their number.

To do this (if you don’t have to maintain high pressure in the system), the engine start mode can be adjusted to 1.5 atmospheres, and the stop to 5 atmospheres, all this is done with an adjusting bolt (compression or weakening of the spring occurs).

Conclusion

In conclusion, we can say that the submersible automatic pumping station for the well is not only mounted by specialists, but independently, but with all the requirements. The ground part of the station (automatics) is most often settled in a house or in the back room, where a caisson is sometimes made (a small cellar).