We make the well hatch independently

Installing the manhole to the well is an obligatory stage of water intake arrangement. The lid prevents precipitation, debris, dust from entering the source, protects against the penetration of animals and birds. And if earlier, whole designs with visors and a collar were more common, now the pump most often pumps water, so there is no need for a device of a complex structure.

Immediately, we note that it is quite simple to make the cover yourself; this will not require any special skills and complex adaptations. Following our recommendations, you can easily cope with this task, and your well will be reliably protected from adverse effects.

Variants of the manufacture of covers of wood

Before proceeding to manufacture, it is necessary to determine what will be the main material of manufacture. We consider the most popular options and the specifics of the work in each of the cases.

Flat covers

Hatches for wells are most often made of wood due to a number of advantages that the material has. In addition, the wood is very easy to process, which is important for those who have no experience with this kind of work.

Before you start manufacturing, you should stock up with a certain set of materials and tools:

- A few wooden bars, they should not be too big, but strong enough.

- Cut edged board, ideal when the material with the grooves - so the joints will be protected as reliably as possible.

- If there is an opening area on the lid, do not forget to stock up on the curtains of the desired size and closing system. This may be a latch or a bolt.

- From the tool, first of all, should be a hacksaw for wood or jigsaw. If self-tapping screws are used to assemble the structure, it is also necessary to have a screwdriver available.

- Do not forget about the measuring tool: roulette, square and construction pencil.

Depending on the chosen configuration, the list of works may differ, but the main stages are performed in the same way:

- First, the diameter of the manhole is determined, and, on this basis, the design is planned.

- The first step is to assemble the frame of the future cover. To do this, use the bars, cut into pieces of the desired length.

- On the upper side, the structure is sheathed with a plank; on the lower side, it is reinforced with one or several transverse bars.

- The top also fastens two cross-beams from the bars, to which one or two handles are attached.

- Installing a manhole on the well requires that it be securely fixed using dowels or anchors. So you protect the design from moving by anyone.

Sometimes manhole cover covers are made with special doors through which you can check the status of structures and equipment. This is especially true in cases where a well ring is used as a caisson for a well.

The size of the door depends on what it will be used for. Sometimes the easiest way to do so is to open one half of a circle. In this case, powerful curtains for gates are used to provide the necessary rigidity of the structure.

If a small hatch is enough, it is placed in the middle of the lid and is equipped with snaps. Remember that the presence of the door requires a significant strengthening of the whole structure.

Tip! If the lid is very heavy, then you can not additionally attach it, the main thing is that from the lower part of it the bars should not be allowed to move and stop movement.

Table covers

Another interesting option that deserves attention. Tools and materials do not differ from the list in the previous chapter, but the type of construction differs.

First, a wooden frame is made, most often it is square in shape. And the upper part is a tabletop, which rises if necessary. The curtains for the construction need to be lifted very strong, as the cover is rather heavy.

Some do not frame, just the size of the manhole cover is made larger than the diameter of concrete rings.

Bench structures

It is much more difficult to make such a construction, but your well will be used as efficiently as possible - both as a table and as a bench.

Doors can be made from above, and if you need to check the shaft of a well occasionally, you can attach the tabletop with latches, then there will be no curtains and handles on the table. Remember that the frame under the bench should be strong enough, the angle stops should be installed every 30-40 centimeters.

Covers-houses

It can be said that such covers were most common in times when water from wells was carried in buckets. The design is very convenient and functional. It reliably protects the well, and at the same time it is convenient to open it often and take out buckets of water.

Works on its device are quite simple:

- First, the size of the manhole cover is determined, and the materials for the frame are cut. Remember that the rings are round, and the base of the house is square, so it must stand thoroughly.

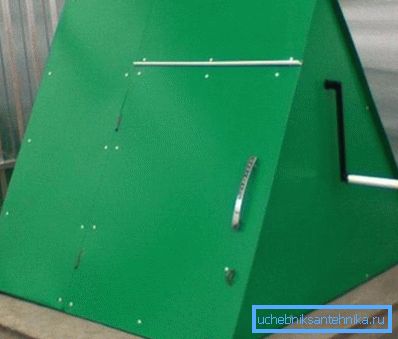

- Further, with the help of screws and perforated corners, a frame in the form of a house is assembled, it should look like this:

- Next, the house is sheathed trim board, and on the one hand the door is made, it is better to attach it to the stiffener and a specially arranged frame. A handle and a latch or bolt are attached on the outside.

- In order for you to ask how to install the hatch on the well did not become an impossible task, it is better to invite 1-2 assistants (their number depends on the weight of the structure).

General rules for working with wood

Remember that any of the constructions you have made serves for a long time, it must be protected with paints or special impregnating compositions. Their price is low, and the benefits are huge, because they protect the wood from moisture and pests.

You should not save on fixing materials, and it is better to use screws - their coating protects against corrosion, and nails begin to rust very quickly.

Metal hatches

This option is used much less frequently due to the higher cost of the material and its low resistance to high humidity and dampness. All metal parts must be treated at least once a year with paints with anti-corrosion additives.

There are several basic manufacturing options:

- The first and easiest is to manufacture a flat, square-shaped cover. The base is brewed from the corner, the design is strengthened with crossbeams. If a sheet with a thickness of 1-2 mm is used for plating, two crossbars will suffice, if tin is needed, it should be strengthened more carefully.

- Another option is a house cover.. The works are performed in the following order: first, the base is cooked, then the house frame is boiled with struts to increase strength. After that, the frame is brewed in which the door will be located.

- The door should be attached to the frame; for this, a hole is drilled in it and the curtains are attached with small bolts.

- The last stage is the construction lining with tin or profiled sheeting., These materials are well protected from moisture and look quite attractive. In addition, you can easily select the desired color option, the most suitable for your site.

This Pay attention! It is better to fasten either with metal screws or with aluminum rivets. The choice depends on your capabilities and preferences. The rivets are easier to work with, but you can unscrew the screws and replace the fragment if it is damaged.

Other types of well covers

It is worth noting that you can buy ready-made options, they can be both wood and metal, and polymer. This material is great for wells due to the fact that it is not exposed to dampness, does not rot and does not emit any harmful substances.

Marking of plastic manhole hatches shows what diameter of well rings they are intended for. They are easy to use, and they do not need instructions - just put the design on the well.

It is possible to combine various materials: sheathe the metal frame with wood, or vice versa, sheathe the frame of wood. It all depends on what kind of material you have in stock.

In addition, for covers often used material such as textolite. It is characterized by high strength and moisture resistance. Most often they sheathe metal frame.

Currently, there are many types of coatings that can be used for covering the lids: moisture-resistant plywood, oriented strand board and much more. The main thing is that the material does not emit any harmful substances and is resistant to moisture.

Conclusion

Do not neglect safety - a good cover for the well not only protects it from garbage and animals, but also protects you and your children from unforeseen situations (also learn how to overlay the well).

The video in this article will help to understand some of the features of the assembly of hatches even better.