We manufacture shower partitions using polycarbonate sheets

In the premises for the adoption of water procedures are usually arranged special compartments to protect the rest of the space from splashing. The main structures are often used shower walls made of polycarbonate, the price of which is not very high.

Yes, and the process of their manufacture is not too complicated.

Positive and negative points

Before directly considering the installation work, it is necessary to become familiar with the positive and negative aspects of this option. After studying the advantages and disadvantages of each developer will be able to decide on the use of polycarbonate (see also the article Use a sealant for showers).

Familiarization with the benefits

- The relatively low cost of sheets makes it possible to create low-cost protective structures.

- The basis is polymer plastic, so this product is resistant to moisture.

- Working with the material is not complicated, which means that the side walls can be erected directly with your own hands.

- Sheets can have different colors, so there is a lot of variations for design decisions.

- The flexibility of finished products makes it easy to abandon the construction of rectilinear structures.

- In the course of operation, various impurities are easily removed from the material surface.

Some shortcomings

- Products can not boast a high resistance to mechanical stress, so it is often covered with scratches and chips.

- When the temperature rises, the material expands, which can lead to deformation if improperly mounted.

- During long-term operation, the sheets somewhat dull, especially if a low-quality product was purchased.

Note! At the present time, shower partitions with a tray can be supplied, the service life of which, when applied with care, is measured in years. The lower part is usually made of acrylic.

Varieties of material

The base material refers to thermoplastic polymers, which tend to restore their characteristics during solidification, regardless of the number of melts. Depending on the production technology, two types of products are obtained, which can be found below.

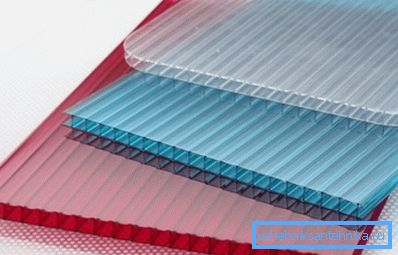

Cellular Polycarbonate

The material is made in the form of large sheets having a cellular structure. This explains the ease of finished products. The popularity is primarily due to the relative cheapness, thanks to which it is possible to create not very expensive partitions for sanitary facilities and showers.

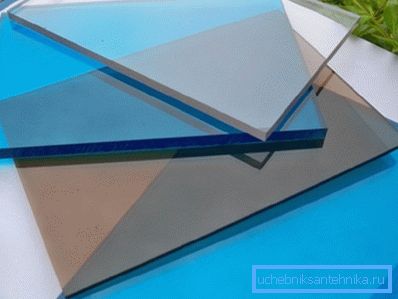

Monolithic analog

Such products are solid sheets that do not contain internal voids. The cost of production is quite high, but with its help it is possible to create structures with increased strength characteristics. In fact, this type of polycarbonate is the most durable of all transparent materials.

A partition in the bathroom for a shower, made using such products, can last for many years. However, for operation under normal conditions, there is no special need to acquire this type of material in order to avoid extra construction costs.

Assembly work

To understand how partitions are made in a polycarbonate shower, you need to fully consider the installation technology of the base material. If during the work the instructions were not followed, or any inaccuracies and errors were made, the design may lose not only in terms of aesthetic parameters, but also strength indicators.

General provisions

- Transportation of products should be carried out in a body having a flat floor without protruding elements. In this case, panels with a thickness of more than 8 mm may protrude no more than 1 m.

- Sheet products must be stored in their original packaging.. They should be placed on a flat surface, but not on the ground. The sun's rays should not penetrate the room, since the effect of ultraviolet radiation affects negatively.

- Cutting elements made using a circular saw or electric jigsaw. It is allowed to use hand tools if it is equipped with a blade with a fine tooth.

| Options | Band-saw | Disk tool |

| Teeth slope | 25-30 degrees | 25-30 degrees |

| Cutting thickness | 1.6-2.5 mm | 3-6 mm |

| Speed | 200-250 m / min | 150 m / min |

Attention! The table shows the main parameters to which the cutting tool should correspond, otherwise it will be problematic to carry out a high-quality cutting of the material.

Component parts

To install plastic partitions for a shower, it is necessary to choose additional elements, without which no installation can do.

For convenience, a number of specialized systems and special parts have been developed, which allow to simplify the work.

- The end profile is intended for decorative framing and protection of the inside against condensation.

- The connecting element is installed on the prepared base so that it is possible to dock two sheets.

- The corner profile is used for the installation of extreme panels in the manufacture of various designs.

- The self-tapping screw is the main fastener that allows you to compensate for thermal expansion.

- Sealing tape is used to close the butt to protect the inner space from the penetration of insects, dust particles and water.

Note! Usually, aluminum tape has a very small perforation, so that condensate that has accumulated inside can flow freely. At the same time insects and foreign particles can not penetrate inside.

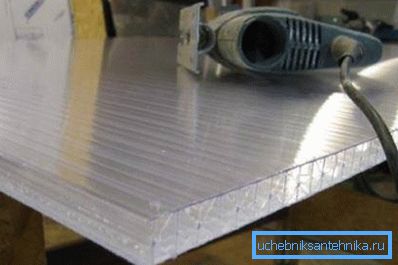

Preparatory work

Before the shower partition for the bathroom is made, it is necessary to carry out preliminary activities, consisting in the preparation of sheets of material for work. Immediately before the installation process, the packaging is completely removed and the temporary adhesive tape is removed.

Immediately, all ends are glued with aluminum tape. In the profiles, fixed to the bottom edge, drainage holes are drilled.

Their diameter should be approximately 2-3 mm. The pitch between them should not exceed 300 mm.

Fastening sheets

When doing a shower partition with your own hands, special attention should be paid to fixing the elements, otherwise the period of operation of the structure will not be very high. As the base fasteners are used screws, equipped with special washers.

The sheet is attached to the supporting structure every 40-60 cm. For each fastener a hole is drilled, the diameter of which should be 2-3 mm larger than that of the threaded foot. When tightening the screw, it is necessary to avoid excessive pressure, so that the integrity of the panel is not compromised.

When attaching, do not release sheets more than 10 cm apart from the support part. Protrusion less than 3 cm is also not recommended. If the panels are not bolted, then you should not leave them in a vertical position, as they may simply break when falling.

The final part

In conclusion, I would like to note that shower partitions can be made with the use of other materials, but polycarbonate has fully proven its effectiveness in such operating conditions. Unlike the same glass, polycarbonate sheets do not crumble into small pieces, therefore they cannot bear direct health hazards (see also the article What are these different sliding shower curtains).

Read more about this material in the video in this article.