Well buildup or two in one

Working with a well is a whole science with its own strict principles and terminology. As in any science, there are also problems with terminology. For example, such an action is not always unambiguously understood, as “buildup”.

On the one hand, it is a process, sometimes quite lengthy, to remove dirty water after the completion of drilling and well equipment. Swinging, on the other hand, is understood to mean an increase in the diameter of an already existing well.

When no definition is needed

In the first case, a submersible or surface pump is used to pump the well. Such a buildup lasts until clean water comes from the well.

The results of this work should be reflected in the well protocol. Moreover, the buildup, like the removal of dirty water, should be carried out every time after a long well shutdown and during its planned technical maintenance work.

Pump connection

Usually for pumping the pump uses a cheaper submersible pump. When the result is achieved, and there is pure water, with regular, daily work a more powerful surface pump is used..

This approach is associated with several significant circumstances:

- Firstly, the use of a submersible pump is much cheaper - it is cheaper by itself, and, moreover, work in the permanent environment of the sludge will lead to permanent stops of the pump - it is cleaned and work continues; Often, with prolonged pumping of the well, the pump simply fails and has to be replaced;

- Secondly, submersible pumps, as a rule, already have built-in filter systems to protect against suspended particles of soil.

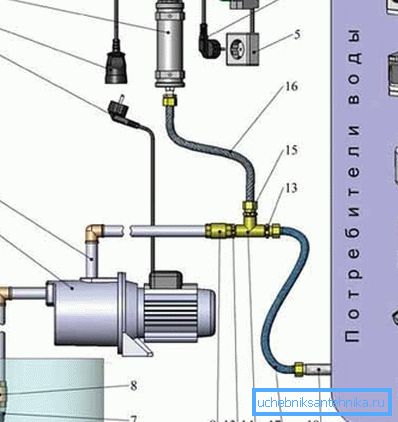

On the diagram below we present the connection of the surface pump to the water pumping system:

- 1 - the entire system is specially equipped with a control unit;

- 2 and 3 - power is supplied from a standard network of 220 V and 50 Hz;

- 4 - operation of the pump in such a polluted environment often leads to overloads, to protect against them, a special circuit breaker is used, which allows emergency shutdown of all work, leaving the entire system, however, in a healthy state;

- 5 - power outlet;

- 6 - well; note that a similar scheme can be applied when pumping the well, and this is the advantage of surface pumps;

- 7 - strainer on the input of the entire system at the very bottom of the water intake;

- 8 - check valve;

- 9 - pipeline of primary, but already filtered water;

- 10 - surface pump;

- 11 - power supply;

- 12 - injection pipe;

- 13 and 15 - nipple;

- 14 - tee;

- 16 and 17 - flexible pipelines;

- 18 - outlet to water consumption systems.

The execution of the pumping-pumping water

Thus, pumping is as follows:

- selection and immersion of a pump or pipeline with a filter;

Helpful advice! If your choice falls on a submersible pump, then we recommend using such centrifugal pumps, they will be better able to cope with long-term loads than vibration ones.

- the exit of the bottom at the bottom must be located at a height of 70-80 cm from the upper level of the lower waterproof layer, if the well is perfect, or from the lower exit of the well, if it is imperfect;

- periodically a pump or filter will need to be removed from the well for maintenance — cleaning and flushing with clean water; it is constantly necessary to be ready for the equipment to fail and replace it with a new one.

Buildup, as the increase in diameter

But often, the buildup is understood to mean an increase in diameter, which is usually done after a long period of inactivity, when you also have to punch. This work is done with the help of the so-called raskatchikov.

Raskatchik examples

The photo shows the three most common types of unroller:

- A - pilot reamer with a diameter of 80 mm, marking "RP-80" with the characteristics:

- diameter of the extended well upon completion of work (mm) - 80;

- diameter of the pilot well, which is intended for future work (mm) - 0;

- length (mm) - 1093;

- the maximum torque on the shaft (kgf / m) - 50;

- nominal - 6;

- maximum axial load on the shaft (t) - 2;

- nominal - 0.5;

- maximum frequency of rotation of the shaft (rpm) - 190;

- nominal - 120.

- B - 200 mm expander reamer, “РР-200”;

- C - section expander-rammer section in 370 mm, "РР-370";

Note:

- marking determines the resulting diameter of the well;

- therefore, the diameter of the roller itself is slightly smaller;

- Roller "RP-80" can be used for drilling from scratch, when there are no wells yet;

- Despite the fact that the model "PP-370" gives a larger diameter compared to the "PP-200", its maximum speed during operation is much smaller.

Types of buildup

The buildup is also called “progling”, which already speaks for itself..

There are three methods for cleaning the well from clay:

- Hydromechanical - the main method of dealing with clay. This method uses the force of a water stream supplied under pressure to the inside.

- Chemical - destruction of silt residues on the walls with hydrochloric acid.

- Physical - impact on silt by vibration.

Helpful advice! None of the buildup methods provides definitive, satisfactory and reliable results for the long term. Therefore, we advise you to use them together and in this sequence: first, we soften the clay with chemistry, then remove it from the walls with vibration, and finally, finally wash everything with clean water.

In addition, there is a buildup:

- internal - it can still be called essentially finishing when a powerful jet of water is used to penetrate the pores of the inner wall;

- and, external - or primary, removal of clay by a vibration mechanical method and bringing it out.

Internal swing

Internal buildup takes place on a fairly simple scheme:

- drill pipes with a rubber piston are lowered into the well below the filter;

- then under pressure, water is supplied, which finally washes away all the clay and brings it to the surface;

- the drill pipes gradually rise to the top so that the pressure will process the wall to the uppermost cut of the soil.

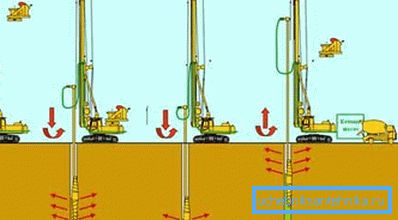

When vibrations are used for the buildup, one cannot do without special equipment:

- A - on the drilling rig is preparing and hanging the roll;

- B - drilling is performed, the process is noticeably simplified if the well is just silted;

- C - vibration, both vertically and horizontally, helps to significantly increase the diameter;

- D - vibration in the horizontal plane is very important and continues when the drill is lifted upwards; at the same time concrete is fed into the well, which is distributed along the walls;

- E - when the drill is brought to the surface, before the concrete hardens, a reinforced frame is lowered inside, which allows you to create very strong concrete walls.

Unconventional approaches

Both of the above actions called “buildup” are found in practice and other useful methods of use:

- First, the technology of vibrational buildup for installation of ramming piles has been developed. In this case, the soil from the well is not removed and moved apart and compacted. The technology allows to increase by 2 times the bearing capacity of the created structure. In addition, the vibration buildup allows pipe laying without digging trenches.

- Secondly, very good results on solid soils give the buildup, as the removal of dirty water, with the help of clean pressure supplied under strong pressure. One of the notable advantages of this method is the high rate of achievement of the result.

findings

And in fact, and in another case, it’s very difficult to build a swing yourself - you will need to use special equipment with photo examples of work. The detailed instruction with the description of each stage of the performed actions will be obligatory.

All this you will find in the additional video in this article, so it will be especially useful in the future. The most important thing - do not forget this duplicity of the term “buildup”.