Well by the rock-do it yourself way: simple and inexpensive

The percussion method of drilling wells is the easiest. However, it is feasible in almost all types of soil. Work can be done without the use of heavy machinery, using a relatively compact installation.

Almost all of its elements can be made in the home.

Features of the method

Based on the foregoing, this drilling technology is the best option for self-development of a water well in your area, the price of which is low.

Drilling rig device

Equipment for impact type of work is assembled from such elements.

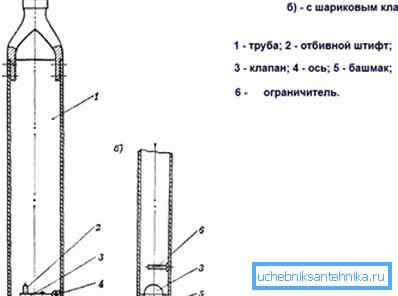

- Drill shell. Depending on the characteristics of the soil, it can be a driving glass, small bowl or chisel.

- Shock rod.

- Rope or cable.

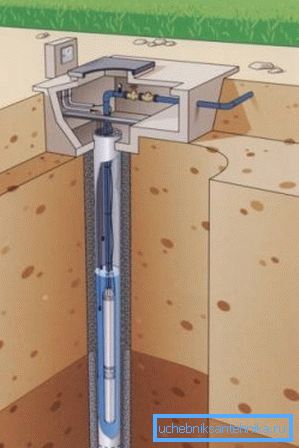

- Tower with a block and a winch.

Padded glasses are the main tool for installation.

- This is a pipe section, in its bottom a cutting edge (fangs or teeth) of highly durable metal, which has a bevel inside the projectile, is welded.

- The edge allows the projectile to enter deeper into the soil layer when stressed.

- An anvil is formed at the top of the drive glass. A barbell hits it.

The technology of percussion wire drilling requires the construction of a tower.

The best option is to make it in the form of a tripod.

- It can be welded from pipes. If you do not have a welding unit, the pipes can be replaced with wooden beams.

- In height, the rig must be longer than the drill. So it can be raised completely above ground level.

- A block is mounted at the top of the tripod. A rope or cable is passed through it.

- The simplest device for lifting a projectile with a cable is a gate similar to a well.

Application of a design with a drop glass

The drilling of wells by the percussion method is carried out as follows.

- The winch rises above the face by the winch, then it is released sharply.

- The glass hits the ground layer and part of it captures.

- Due to the friction force, the soil is held when lifting in the cavity of the container.

- To make the projectile go deeper, a shock bar is used. To do this, it must be raised and released. At the same time she hits the anvil of the drill projectile.

- When several blows are made, the filled container is lifted and emptied of its contents.

- Further, drilling operations are resumed.

Note! Shock-wire drilling with their own hands with the help of driven glasses can be carried out only when working on relatively soft and non-flowing soils. Sand particles are almost not interconnected. Therefore, the friction force can not hold them in the cavity of the driving glass. For the arrangement of water supply facilities on hard and sandy soils, other drill shells are used.

Use of technology on loose soils

For work on sandy soils, yolks are used.

- At the bottom of such a projectile has a valve. It opens when the container hits the rock, thereby allowing part of it to get inside.

- When lifting the yellowfish, under the pressure of trapped soil, the valve closes itself, which prevents the contents from waking up.

- On the surface the container is released, further drilling continues.

When the percussion drilling of wells with his hands is carried out on a homogeneous bulk soil or with layers thereof, he begins to fall asleep bottom.

- To avoid this, it is necessary in the course of work to strengthen the wellbore casing.

- On the first pipe you need to make an expansion (conical) shoe.

- In the process of increasing the length of the face, the segments of protection under the action of its own weight or due to accurate shocks, descend from top to bottom.

- The casing section must be slightly larger than the diameter of the drill projectile. So he will move freely in the trunk. In other words, the diameter of the bottomhole itself will be smaller than the cross section of the pipes, therefore, part of the soil from its walls will be cut by them.

Hard Ground Option

For work on solid or stony soils, the instruction prescribes the use of a drill bit.

- Its powerful blows split and crush hard ground.

- The resulting small particles rise from the bottom of the face of the scab.

Note! When working on solid soils, the casing will not be able to cut the rock from the walls of the face. Therefore, together with them you need to additionally use the extender. Such a device has movable cutters.

- To bring the expander to the bottom of the borehole, the cutters fold it up so that the device fits in the casing.

- When it is below the end of the column, the spring puts the cutters in working condition. They cut the soil from the walls of the trunk, increasing its cross section.

- In order to pass intermediate aquifer lenses in the drilling process without any problems, casing strings should be installed on solid soil types. Otherwise, the groundwater will flood the face and interfere with the work.

- To block the aquifer, it is necessary that the bottom edge of the column rests against the soil layer located below the water. Next, the fluid is pumped out. Then, particles of the rock are removed from the face with the help of a little gelon.

Important points

- Before drilling a well, you first need to dig a hole that is 1.5 × 5 meters in size. Its depth can be up to two meters. This pit is needed so that the loose surface layer of the soil does not collapse into the face. The walls of the hole are strengthened with boards from boards. Further above the place of works the tower is mounted.

- When manual or pneumatic impact drilling is carried out, it is necessary to control the flatness of the face.. Its curvature will cause difficulty installing the casing or its installation will be completely impossible.

Note! The longer the drill string, the easier it is to maintain the evenness of the wellbore. Therefore, its optimal length should be about two meters.

- The cable used in the described method of drilling a well should have a large safety margin. It must withstand the mass of the drill string and the shock bar. In addition, the cable must hold a strong strain on the gap when raising the glass or chisel hammered into the rock.

- In addition, with the shock method of drilling, there is a likelihood that the projectile will jam at the bottomhole, as a result of solid ground between it and the casing wall.. On this basis, the cable cross-section must be at least 1 centimeter.

Conclusion

When using drum-type drilling, there is no need to use complex and expensive equipment, as well as special equipment. If you wish, any site owner who has skillful hands, together with one or two assistants, can cope with the work. Watch the video in this article, in it you will find many more useful things on this topic.