Well cementing - key features of the process

If the well operator at your site has concluded that the source needs additional reinforcement, you should not ignore the recommendation, since your water intake may collapse in a few years. Well cementing is a rather complicated technological process, which makes it possible to strengthen the source column and make it practically non-susceptible to damage.

The process consists in filling the peri-tubular cavity with a special cement mortar, which is also called cement slurry. After its solidification and a set of strength characteristics, a material is obtained that is almost as hard as a stone.

The main types of work carried out in the framework of the process

We note right away that it is practically impossible to do the work with your own hands without special equipment; high quality of work is achieved only with strict observance of all stages of the process. The price of this service is quite high, but these costs are fully justified.

The whole workflow can be divided into several main stages, let's consider each of them in more detail:

- Preparation of a special solution for filling the cavity. Since the highest requirements are imposed on the composition, it is best to use special grouting Portland cement, which provides the solution with the highest strength.

- The finished grouting composition must be delivered to the well, as it freezes quickly enough, the easiest way is to use special equipment on the vehicle platform, in this case all the necessary operations will be carried out right on the spot.

- Next is the injection of the annular space of the cement composition. This operation can be performed in two ways, each of which we will consider below.

- After that, it is necessary to let the solution harden and gain certain strength characteristics. The time required depends on several factors: the grade of the solution, the depth of the well, and the specifics of the work.

- It is also necessary to check the quality of work and identify all factors: layer thickness, filling uniformity and other factors.

Note! Before starting work, it is necessary to carry out numerous calculations that should take into account all the features of the cemented well. On their basis, a detailed work plan is drawn up.

The main methods of pumping solution

Methods of cementing wells are divided into types depending on how the plugging solution is fed into the annulus and which devices are used for this. Several main methods are widely used, which we will consider.

Cementing solid type or single stage

This method has the following features:

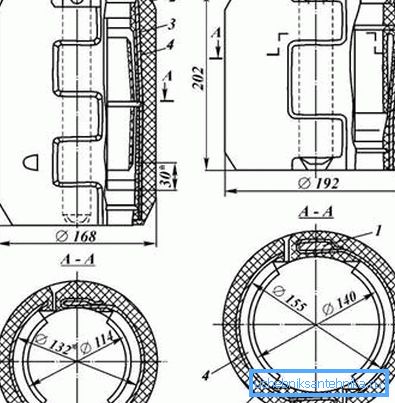

- The composition is pumped directly into the casing with a special device.

- The solution moves through the entire column up to its base - the shoe.

- Next, the mixture fills all the annular cavities, moving from the bottom up - from the base to the surface.

Industrial organizations often use this method, as it can be used to achieve a much better result. Most often, the work is done in one cycle, with this option it is important that the entire required volume of cement composition is pumped into the well and pushed immediately into the annulus.

Consider the features of the process:

- Initially, all cavities are usually cleaned. The well is filled with flushing fluid.

- Work begins with the entry into the well of a special device - the lower tube, which will serve as a limiter.

- Then begins the injection of the required volume of solution, in the process of which the tube gradually goes down.

- When the entire solution is loaded into the well, the upper plug is put in and the mixture begins to be pushed down the well column until the lower plug stops against the restrictive ring at the bottom of the system.

- The punching continues until the upper stop stops against the bottom and the entire solution goes into the annular space, rising from the bottom upwards as it is filled.

Two-stage system

This method has its own characteristics, which we will consider:

- All work is done as follows: the lower level is separately sealed, and the upper one separately. This is necessary in cases where the temperature indicators of the levels vary considerably or the amount of solution required for the work is too large.

- Even before the start of work, a special device is put in place to distinguish the layers: a separating ring.

- There are two ways to work. At the first stage, the lower layer is first poured, and after it hardens, the upper layer is pumped into the cavity. The second method involves the simultaneous injection of a mixture of both the bottom and top.

This method is most often used with a large depth of the object, for its implementation requires the presence of sufficiently serious industrial equipment.

Lip-type cementing

This method is used in cases when it is necessary to isolate only the upper part of the well. The required level is determined to which the filling will be made. At this mark on the casing pipe is fixed a special cuff.

To fill the solution in the column should be provided perforation.

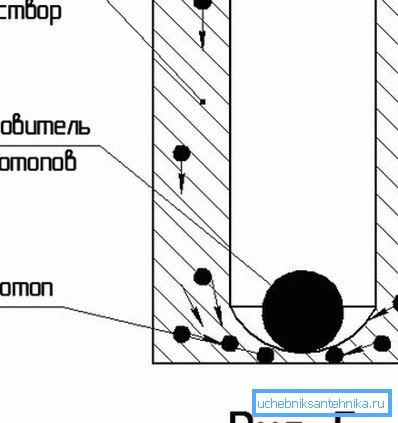

Reverse cementing

This method differs from the above:

- The solution is not pumped through the casing, and through the cavity enters the annulus.

- The solution pushes fluid through the casing as it enters.

This method was not widely used as it is very difficult to control when the solution reaches the bottom of the column. In addition, with this method it is impossible to control that the solution below has all the necessary strength properties.

Comment. Typically, the customer does not choose a specific method of work, it is determined by the contractor, depending on the characteristics of the well and its own equipment fleet.

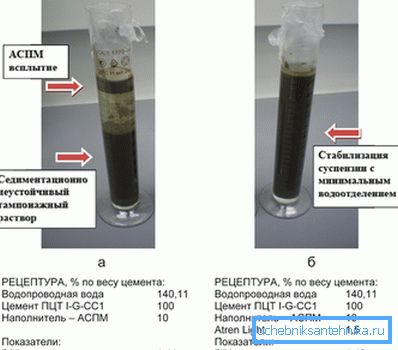

Factors on which the composition of the cementing solution depends

The solution prepared to fill the near-wellbore space may differ in composition depending on the conditions in which it is used:

- The higher the temperature, the faster the solution will set - this factor should always be taken into account.

- The higher the water content in the solution, the better it fills all the cavities. But at the same time, the composition dries much longer and, when cured, gains lower strength indices.

- Types of cements and additives to them. Various types of cement are used for work: from special grouting varieties to quartz, fibrous and self-expanding compositions. And additives can give the composition a truly unique properties, but their cost is quite high.

What equipment is used in the production of works

The set of necessary units is quite extensive, they have considerable weight and impressive dimensions, so most often they are placed on the platform of powerful vehicles, both domestic and foreign production.

The source of energy for these complexes of equipment is the car engine, so they do not depend on the laying of energy lines.

Automotive installation independently conducts the entire technological cycle:

- First, a precisely metered amount of cement is added to the tank, after which a certain volume of water is supplied.

- The mixture is thoroughly mixed and ready to use.

- Next, special pumping equipment under high pressure delivers the composition to the casing.

Aspects of quality control work

After completion of work and hardening of the solution, the quality of cementing is assessed.

There are many methods of verification, we will discuss in more detail the main three:

- Radiological method - in this case, a special device with gamma-radiation is placed in the well; it is fixed by sensors spaced radially across the entire surface. The method is simple: if during the descent the diagrams are uniform and do not differ over the entire height of the well - the work was carried out at a high level, if there are jumps - the concreting was performed with a marriage.

- Acoustic method - its essence consists in passing acoustic waves through the casing walls. If there is a cement cover around - the waves die out very quickly, if it does not exist, they spread unhindered. The method is quite convenient: all data is received and analyzed by the computer and outputs the finished result.

- Thermal method based on the property of cement mortar to release heat during solidification. Instructions for its use are simple: you should measure the temperature of the walls at different levels of the casing, so you can easily determine the level to which the mixture has risen.

It is worth noting that in cases where the cement bridge is poured into the well, i.e. layer, separating the levels or layers of soil from each other, to determine its thickness and strength is impossible using the above methods.

Conclusion

Despite the high cost and complexity of such works, they are highly popular for several reasons:

- As it is known, there are not one but several aquifers in the soil. Cementing allows you to combine them and significantly increase the flow rate of the well.

- Filling the cavity with a solution serves as reliable protection of steel pipes against corrosion and significantly increases the life of the structure. Excess costs are paid off with high durability and extended service life.

- The strength of the system is greatly increased - it becomes almost invulnerable to the movements of the ground and its thermal deformations.

The video in this article will help you better understand how well cementing should be carried out.