Well cementing

Well cementing is the last step in its construction. The main purpose of well cementation is to isolate the exploited aquifer from the overlying non-exploited ones, to fasten the walls of the well in loose and unstable rocks, as well as to protect the surface of casing metal pipes from corrosion. Depending on the hydrogeological conditions, cementation is performed to the full depth to the wellhead or in a certain interval.

Some people confuse cementing with a liquidation plugging of wells, the purpose of which is to protect artesian water from contamination. This process is called cementing, or tamponage, which implies the elimination of a well by filling it with a solution (usually under pressure).

Types of cement slurries

For cementing wells using a special solution based on cement oil cement. Cement grouting cement differs from ordinary ones with improved mechanical properties after hardening by slower setting times. The composition of the solution is selected depending on the geological and natural conditions.

- Sandy cement is a mixture of 80% cement oil and 20% quartz sand. Such a solution has good adhesion with rocks, is used for cementation of areas and conductors.

- Fiber cement. This cement is used to reduce the depth of penetration into the cracks of rocks that have a small reservoir pressure, or if it is necessary to eliminate the absorption of the washing solution. This solution is prepared from cement cement with fiber additives in an amount of from 1 to 3%, used as additives (asbestos, paper).

- Expansion cements - used to create durable impermeable cement stone. Such cements during hardening increase in volume to 2%. Expanding cement is obtained when used as an additive diatomite, ruffled.

Each solution has certain setting times, which are regulated by special additives. In order to slow down the process of setting, surfactants (surfactants) are used, it is necessary to slow down the setting if you need to cement deep wells, when pumps with low productivity are used or if the wells are heated with thermal waters. For cementation of shallow wells, accelerators are added to reduce the setting time: sodium chloride or calcium chloride in the amount of 1–2% by weight of dry cement.

One of the main indicators of cement mortar is the water-cement ratio, that is, the ratio of the mass of water to the mass of dry cement, and it is 0.4–0.5. If you increase the amount of water, then the tensile strength of the cement stone will decrease and it will set longer. With an increase in the amount of cement, the fluidity of the cement slurry decreases.

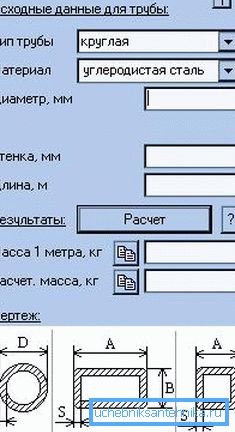

Calculating the amount of mortar and cement

Cementing methods

Well cementing is usually performed in a single-stage scheme with one or two plugs. In practice, these methods are used to supply cement slurry into the well:

- Direct injection of cement slurry into the annulus, the solution with this method moves from top to bottom. Differs in speed of performance of work, but the quality of cementing is low, this method is used in shallow wells.

- Reverse cementing is considered more difficult to perform; according to this technology, the solution is pumped directly into the inside of the casing, and the solution is squeezed into the annulus using water or clay under pressure. The solution moves upwards. To avoid mixing the solution with squeezing liquid, lay a separating tube, one or two.

For deep wells, cementation is carried out in several stages in separate sections.

If the well design has a telescopic structure, cementation is performed at each stage of the pipe section installation, drilling continues only after the complete solidification of the solution.

Mounting cementing is used if tamping of the annular space located above the bottom is necessary, for example, when the water-opening column is simultaneously operational, and the filter is at the bottom. Installation cementing is also used in the repair of wells and to eliminate leaks in the pipe columns.

In all cases, cementing after pouring the solution into the well is left alone for curing. For conductors at 12 o'clock, and for production columns at 16–24 hours, under pressure, which was at pushing.

Units and mechanisms for grouting

The mixing of cement and the injection of the solution into the well should be done in the shortest possible time, this necessitates their maximum mechanization. The solution is mixed with hydraulic cement mixers. To supply the solution to the wells, cementing units are used, which are mounted on the chassis of the car and which include a water pump for pumping the solution, a tank. The main parameters of the cementing unit are the capacity and pressure that it creates. Cementing heads are used for cementing.

Quality check of tamponage

After hardening of the cement mortar, the casting head is removed and the drills and cement are drilled. This part of the cement is called the cement cup. When checking the quality of the cementing, they first test the tightness of the column, and then the tightness of the annular space. The leak test technology is based on the differential pressure of the fluid in the annulus and casing. Pressure testing is carried out with clean water, for this purpose, the filling head is screwed onto the column and using a pump to create pressure in the column up to 60-120 atm and leave it under this pressure for 30 minutes. If after a time the pressure drops by no more than 5 atm, the column is considered hermetic.

The life of the well depends on the quality of the cementation of the well, so much attention is paid to cementation, cementation cannot be carried out qualitatively without the involvement of drilling organizations with special equipment.

Video

This video describes a cementing unit for wells with a piston pump: