Well construction: what you need to know

Water well construction is one of the main and most important sections of the technical part of the project for the construction of a structure. To competently draw up such a project, it is necessary to understand the components of this design and their purpose.

We will talk about what the well consists of and how its parts interact.

Device wells

General provisions

As is known, any construction begins with design, and one of the most important questions that must be answered as a result of design work is a concrete look that the artesian well design will take..

Develop and refine the design of the future structure in accordance with one or another specific drilling conditions characteristic of the area.

The ultimate goal is to complete the task, that is:

- Achieving the design depth of the bottom, which will allow to produce the planned volume of water per unit of time throughout the predicted useful life;

- Successful discovery of the aquifer. This is a necessary condition for the correct operation of the structure, because not only the flow rate, but also the quality of the produced water will depend on how well the opening and development of the aquifer is carried out;

- Achievement of the possibility of carrying out the entire complex of the planned works, including research, exploration, mining operations, etc.

At the same time, the following factors will influence the configuration and design parameters of any well:

- Selected in accordance with the data of geological exploration method of drilling and the passage of problem sections of the section. The equipment used and the complexity of the fortification of the trunk by casing strings, cuffs, glands and other devices will depend on the method of rock development used;

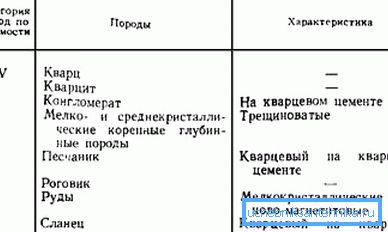

- The complexity and features of the structure of the geological section. It is important to take into account all possible complications associated with problem areas and features of the breed in them. It is necessary to immediately select the drilling equipment and methods of isolation of unexploited productive formations, as well as methods for protecting the shaft from collapses, landslides and overflows;

- The purpose of the well. Depending on the extracted mineral, the construction device can vary greatly, including the depth, diameter, materials used, equipment, etc. A separate group consists of research, intelligence, parametric and other special objects;

- The method of opening the aquifer. An important factor that determines the structure and design of the production and filter pipes, sump, submachine grouting and many other parts of the well.

Note! The design of the facility must comply with the rules and regulations adopted in the decrees of the Gosgortekhnadzor of the Russian Federation, as well as the requirements for the protection of the subsoil and the environment. The project of the future facility is subject to mandatory approval by the controlling authorities, primarily in the district office of the Gosgortekhnadzor of the Russian Federation and the SES.

For the interval of the productive formation, the choice and justification of the structure are reduced to ensuring the best conditions for the flow of water.

This particular part of the well should be capable of solving such problems:

- Providing and implementing the best conditions for the development and drainage of the productive (aquifer) reservoir;

- Setting the parameters of the burial of the object in the aquifer of the rock, which can provide the most productive long-term production of drinking water;

- High-quality effective isolation of the productive layer from adjacent and nearby aquifers in order to avoid overflows and water mixing;

- Protection of the productive aquifer from the harmful effects of the cement slurry used in cementation, or the full reduction of the effects of this influence on the permeability of the water reservoir rock.

To determine the basic parameters of the structure and the necessary measures during the construction of the well, a study of the geological section is made, according to the results of which conclusions are made regarding the location and characteristics of the main intervals that need isolation by casing strings.

These may include intervals of catastrophic acquisitions, highly plastic clays, salt-bearing layers, aquifers, loose rocks, and intervals with incompatible drilling conditions.

Casing Column

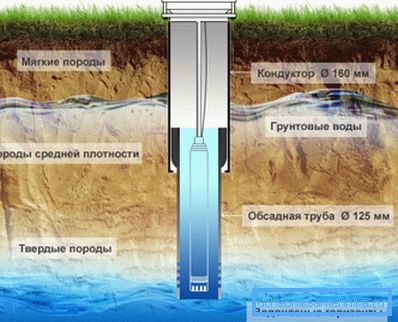

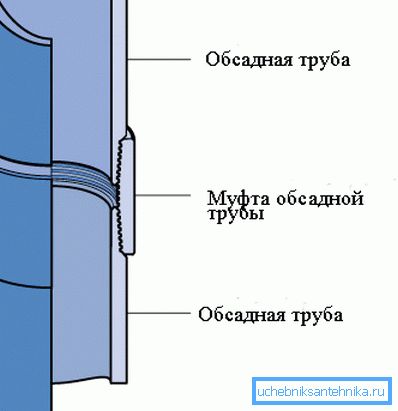

A casing string is a system of pipes that are lowered into the wellbore to strengthen it, as well as to isolate dangerous layers and layers with incompatible drilling conditions. This is one of the main systems for the design of mining and not just wells.

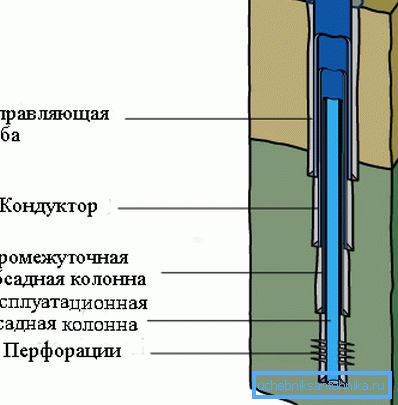

By appointment and device there are four main types of casing:

- Direction. This is the name of the uppermost pipe, which is installed primarily to protect the structure's mouth from erosion and landslides;

- Conductor. It may begin construction, playing the role of direction, and may continue it. It is used to protect the upper loose layers of the section from collapse, to isolate groundwater aquifers, and also to install blowout equipment at the wellhead (if necessary);

- Intermediate. It is used when complications arise in the process of drilling deeper layers for fixing and isolating overlying intervals, the drilling conditions of which are incompatible with the drilling conditions of subsequent layers of the rock. With the passage of the same type, durable and stable layers is not used;

- Operational. The lower part of the column, which serves to extract water and isolate unwanted horizons.

At the device of the directing site the concrete glass from ZhB of rings or casting can be used. The use of steel casing of large diameter is also allowed.

To install them, a hole is drilled with a depth of 4–8 meters to the level of occurrence of resistant soil rocks, which are most often a waterproof sole for the groundwater horizon.

A pipe of the required length and diameter is installed in the hole, after which the space between the pipe walls and the hole is filled with rubble stone and cement mortar to eliminate the possibility of overflowing of the water pipe and the groundwater of the sandy formation.

Next, a plot is developed to a depth of 50 to 400 meters, and the next column is installed in a drilled well shaft - a conductor - consisting of welded steel pipes. The annulus is also cemented to better isolate problem areas.

Then attempt to drill the mine to the design depth. If this fails, the auger rests against the complicating horizons and it becomes necessary to overlap unforeseen or not planned for exploitation productive strata, then an intermediate column is mounted into the barrel.

Then the process can be repeated several times, and the number of intermediate columns in this case increases.

Finally, upon reaching the design bottomhole depth, a production string is installed in the well, which is designed directly for the extraction and extraction of fossil water onto the surface.

At the very bottom, at the shoe, there is a zone with perforation of the pipe (filter column) and cement stone, which serves to collect and filter water from the well from large particles of rock.

Note! The casing gap is also cemented with cement slurry, for which a cement cuff is made at the lower end of the pipe, which prevents the solution from penetrating into the aquifer. For the cementation of the upper pipes, special seals are used for these purposes.

Pipe joints in the columns are produced using threaded couplings with multidirectional threads. Various adapters with a conic section can be used for the articulation of the columns; in this case, the use of stuffing boxes is optional.

Permits

If you decide to build a well on your own site with your own hands or with the involvement of a professional organization, you will need permission.

It can be said otherwise: you will hardly succeed in drilling an artesian well yourself, and the drilling company will not even discuss the possibility of starting work in the absence of permissive documents.

To obtain them you should contact the local authority - the geodesic center. The geocenter of your area will consider the appropriateness of drilling, and if you do not have alternative sources of water supply, then you will most likely be given prior authorization.

Next, you will take all kinds of inspection bodies that will study the terrain and assess the water reserves in this aquifer, taking into account the already constructed and used wells.

You will need information about upcoming work and activities: the design and depth of the well, its exact location on the site, the estimated amount of pumped water and drilling technology.

Based on the information you provide, the team of experts decides whether there is enough residual flow rate of the source to meet your water needs without adversely affecting the functioning of the region's ecosystem.

Also, the instruction involves testing your ability to provide the necessary sanitary and technical safety of the territory (the possibility of creating an exclusion zone around the wellhead, moving septic tanks, sewage, compost pits and parking lots) outside this zone.

As a result, with the successful completion of all stages of registration, you will be granted a permit and a license for the well. The license indicates the owner's name, address and characteristics of the well, because it is a capital object, the price of which may exceed the cost of residential real estate. Upon completion of construction, you will be issued a technical passport to the well.

Conclusion

The design of the well and its design are interrelated and fundamental stages of preparation for the construction of a deep water production structure (more than 30 meters). When working, all the nuances of the geological cross-section and the possible danger of contamination and overflow of water should be taken into account, and measures should be developed to eliminate this danger. The video in this article will help to understand the topic in more detail.