Well cover: functional models and their production

A durable well cover can be made of any materials available on the farm: wood, plywood, metal, or modern plastic. In addition, this part of the hatch, made independently, is not inferior to the practical in its practicality - the protection of the mine.

Reliable shutter solves the following tasks:

- protects the mine from debris, dust, precipitation, birds and animals;

- protects children and adults from falling;

- provides adequate ventilation of the well;

- prevents freezing of water.

Types of covers for wells

Materials for covers are various:

- tree;

- metal;

- plastic;

- concrete.

Of wood

Traditional wooden covers for wells harmoniously complement the rural landscape. Of course, we will make them ourselves from wood, since this material is easy to process (also learn how to make a lid on the well yourself).

The size of the structure and shape will be determined by ourselves, taking into account the style of other structures in our suburban area and the diameter of the well.

Tip! The simplest cover on the hatch will double to protect the source from frost. By the way, folding option is more convenient than removable.

The instructions of the experts for the manufacture of a solid bar cover advise the use of the following materials:

- 6 bars 20x30 cm;

- boards with hewn grooves;

- roofing material;

- hinges or rubber strap;

- comfortable pens.

We work in a certain sequence.

- We measure exactly the external size of the well.

- We will make with our own hands a crate of bars, commensurate with the creation itself.

- Obeshem tesom finished crate.

- Fasten the lid inside the center of the additional beam.

- Similarly, we will make the second door.

- We install the handle in the door.

- Now we will fix one with the help of hinges or a rubber strap on the lower section created, and the other on the upper one.

- Lacquered or painted the finished cover.

Of course, the price of such a homemade product is minimal.

Note! The well door must be very firmly attached to the work using a sheathing of bars or metal corners.

From PCB

The double cover for wells with a heater will serve decades.

For this design, in addition to sheet textolite are also needed:

- concrete or cement;

- metal corners;

- sealant;

- shaped tubes;

- hinges, handles.

From tools besides the welding machine we need:

- roulettes;

- hammer;

- screwdrivers;

- Bulgarian;

- the bolts.

Manufacturing:

- According to the measurements, we cut at a 45-degree angle metal corners;

- Welding connect them into a quad;

- The corners of the frame are also welded;

- Traces of welding we clean the grinder;

- We will cut the profile pipes 1 cm shorter than the corners, insert them around the perimeter into the finished frame and weld all with a welding machine;

- Welds will be removed grinder.

Installation:

- Cut out from PCB 2 plates on the frame;

- Install insulation between these sheets;

- We fasten the construction together with screws;

- We seal all the seams on it;

- Loop the cover with the frame by welding, but it can be bolted.

Now the lid for the well is ready, but to install, we will make formwork from boards and we will cement it. Painting, installing a lock and pens will not be difficult for us.

Covers for sewer well

This component of the manhole is installed in the hatch body.

Lid Features

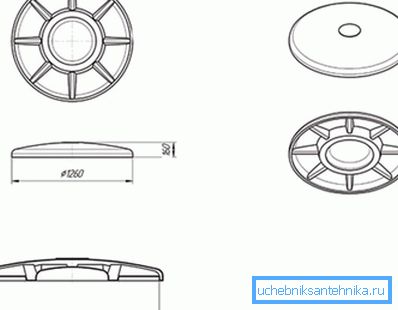

The disk will never fall into the mine, as its diameter is larger. Therefore, it is round covers for sewer manholes that save both material and space. In addition, we can easily roll them, because the weight of 1 standard sewer is 50 kilograms (so that it is impossible to accidentally move it).

Note! It is faster to open the round lid - just pry it off from any side, and the mouths of such wells are also round.

Material for production

For any material, we still need a metal rim with welded hinges.

- The cast-iron monolithic cover for the sewer well is very heavy even with a small thickness.

- Concrete slabs are also heavy, but less durable, however, they are an acceptable option for autonomous sewage, especially since we can make them ourselves.

- Now popular covers made of durable plastic.

Dressing

- An artificial boulder, as a decorative detail, will hide an unsightly object. These elements keep their novelty and attractiveness for a long time, without losing color and shape from the scorching summer sun or from precipitation and frost. With the inevitable regular revision of the well, we will easily remove the artificial boulder and leave it behind.

- At the top of the lid there is a cavity for fertile land and flowers - it means that we can make a blooming fragrant flower bed from a simple unsightly lid for sewage. They are made of very durable polyethylene, which, of course, is not susceptible to corrosion.

Note! Installing such a decorative cover on a septic tank will provide us with many creative ideas for the landscape, because there we can put flowers, make a picturesque pattern of stones or sand, and even arrange a mini pond.

Conclusion

The manufacturing process is divided into stages:

- specification of the sizes created;

- production of reliable crates for these indicators;

- fixation in the center of the hatch of the reinforcing bar (bottom side);

- attaching a hinge or high-quality rubber strap for convenient lifting of the cover;

- installation of handles to the lid;

- coloring and dressing.

The closures closing the wells and sewer manholes are multifunctional. A beautiful decorative cover for the well is a winning element of the landscape, its original decoration.

The video in this article contains additional information about this element of the well.