Well do it yourself: the necessary information

A well is sometimes the only source of drinking water outside the city. The construction of a well construction is difficult, but a task that is feasible for a man, and more often this procedure is simply necessary. We will tell how to lay out a well from a brick the hands, and also we will concern many other useful subjects.

Well device

General information

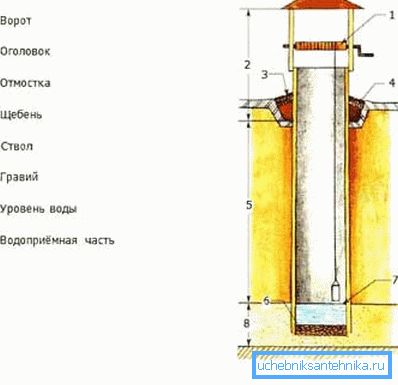

In general, well construction consists of the following parts:

- Gateway. It is a lifting mechanism in the form of a rotating log, on which is wound a chain or cable with a bucket at the end. Instead of the gate, you can use a “crane”, but it takes a lot of space and is somewhat more difficult to manufacture, and the technology itself is considered obsolete;

- Cap. This is the above-ground part of the casing shaft, which usually has a roof, cladding and other means of protecting the mouth from foreign interference. It can also be equipped with benches, table, lid with lock and other amenities;

- Blind area. It is made around the tip after a complete subsidence of the soil (1-2 years) for the discharge of sedimentary water from the mine;

- Clay castle. It is made around the upper part of the shaft to protect the structure from the penetration of surface water into the well;

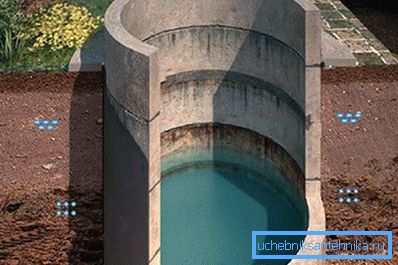

- Mine shaft. It is a cylindrical pit, lined from the inside with a column of concrete, stone, brick, wood or plastic. It serves to keep walls from collapsing, and also does not allow undesirable water to penetrate inside;

- Gravel bottom filter. The bedding is at the bottom of the well, through which water flows into it (with an imperfect construction). In the buildings of the perfect form or with a sump bottom filter is not needed;

- Water intake part. Segment of the mine from the bottom to the static water level (mirror).

Thus, it turns out that the well consists of three main parts:

- Tip;

- Stem;

- The water intake.

The head is the mouth and allows you to easily get to the water, as well as lift it from the depth and without problems pour into the desired container. In addition, the top of the well with your own hands can be turned into a real decoration of your site. There are real gazebos and houses around the mouth, as well as mini-options, hidden in a box with a roof for a well.

The barrel keeps the mine from collapsing and insulates the tank from unwanted rock strata, which can carry not quite clean water.

The water intake allows water to accumulate to the natural level and save its supply to users. In addition, in this part the final filtration of the liquid from the suspension of sand and other particles takes place.

Note! Depending on the specific tasks of the device structures may vary, but the main parts remain unchanged.

Varieties of water intake structures

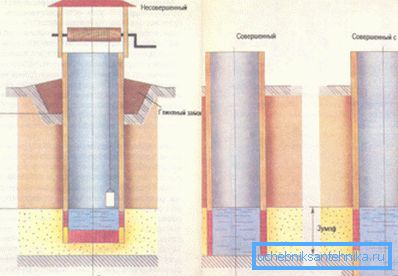

According to the design and depth of the receiving part, there are three types of wells:

- Imperfect or incomplete. This species is distinguished by a shorter mine, which does not reach the impermeable bed. Water is taken in through the bottom by infiltrating the fluid contained in the aquifer, by volume it is the most filled type;

- Perfect. In this species, the mine reaches the bottom of the aquifer and abuts against an impermeable layer of rock. At the same time, the total volume of the liquid increases due to the depth of the water intake, as well as a more active inflow;

- Perfect with a sump. Here, the mine does not end at the aquifer and has a recess of one and a half meters in the rock to increase the volume of water intake. Sometimes the sump is completed in case of a decrease in the performance of the core or an increase in water consumption.

Note! For the needs of one average family with a standard household and home farm, the productivity of an incomplete structure is usually enough. Its construction is most suitable for independent execution due to simplicity.

Building

Casing Varieties

You can build a well in various ways.

Regardless of the structure and design of the structure, its shaft can be strengthened in several ways:

- Log of logs or boards. This method is considered the most environmentally friendly and traditional, but the price of high-quality wood and work on its assembly and installation is very high, which makes this method unpopular in our time;

- Brick or masonry. It is a strong and reliable method of casing, but here you should also remember about the cost of materials and the complexity of the work, since laying out a brick or stone shaft without experience and skills of such masonry will be problematic;

- Concrete rings. The most economical, safe and easy way to build a trunk, since the work takes place simultaneously with the casing, which protects the worker from damming with earth. You can build a monolithic barrel, but it requires the skills to build complex floating formwork and knowledge of the basics of concrete work, rebar and other subtleties of the construction craft;

- Improvised materials. Here the field for activity is unlimited: use metal pipes, plastic pipes and barrels, all kinds of products in the form of rings. Some craftsmen build a well of tires with their own hands, but we do not recommend using such materials for storing drinking water.

Note! The well service life will depend on the quality and strength of the casing design, and the quality and taste of water in it will depend on the materials used.

Brick well

For those who have not yet decided on the material of the casing of the mine, we will tell about the construction of a brick column.

This method requires the skills of laying and certain construction skills, so it is not suitable for everyone:

- In the previously found place we begin to dig a hole with a diameter of 1.2 - 1.5 meters. Depth - to the level of the chest;

- We put a tripod with a lifting block or a winch above the pit to raise buckets and stones from the depth;

- We dig the earth before the appearance of the aquifer, when the water has gone - we pump it out with a surface pump;

- The bottom is filled with a layer of oily waterproof clay, which is thoroughly rammed. If water oozes out of the walls, then we enclose this area with a piece of plastic barrel without a bottom or a piece of pipe (diameter - 1.15 - 1.4 m), and fill the space between the walls of the pipe and the shaft with clay (we make a lock);

- The surface of the clay bottom is leveled, and on it we fill in a concrete ring for a well with an internal diameter of 90 cm.

- When the concrete froze, we start laying the walls. We use brick exclusively clay, well burnt, without cracks and flaws. Putting masonry, shifting the rows by a quarter, filling the cracks on the outside of the masonry with rubble and mortar;

- If the well is perfect, then on the entire aquifer of the soil we leave small gaps between the buttings - 1–2 cm, but not in each row, but through the row, or we place them in a staggered pattern;

- We lay out the whole mine and build a cap above the ground;

- When the solution has grabbed, we descend to the bottom and dig out the clay, and also remove the casing of the aquiferous zone of the soil;

- At the bottom of the structure we make a gravel bed, if the structure is incomplete;

- We are waiting for the reservoir to be filled with water, then (after 2–3 days) we pump out the water until it becomes transparent;

- Around the walls of the tip we make a clay castle;

- We build a roof or a shed from rain and debris above the tip, we plaster the head itself, revet it with stone or wood, and between the racks of the shed we install a lifting gate with a handle and a chain;

- The mouth is closed with a tight lid.

Note! If the depth of the aquifer exceeds seven meters, then it is better to abandon self-laying according to this scheme, since there is a great danger of collapse and accidents.

Safety at work

Excavation work falls into a particularly dangerous category, especially with regard to digging narrow and deep mines. There is a high risk of soil collapse from the walls of the trunk, as well as the constant threat of falling dangerous objects down.

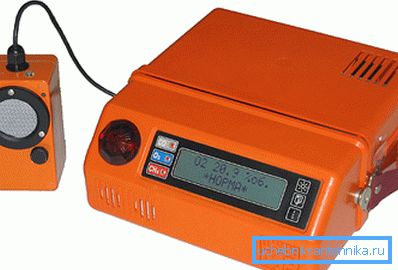

In addition, you will raise the buckets with earth on the rope, and this adds extreme to the process, as the bucket can fall off or tip over. But the most serious danger is natural gas, which can accumulate in the mine and poison workers to death.

Portable gas analyzers are used to control the gas level; if they are not there, a candle can be lit at the bottom: a fading wick speaks of danger. To remove the gas, you can use a vacuum cleaner, a fan, various webs, which are lowered repeatedly on a rope downwards and upwards.

While working in the mine shaft, the ladder should be constantly lowered, and the worker should be tied up with a safety belt with a cable for which it can be lifted. He always has a helmet on his head, glasses on his eyes, gloves on his hands. Working at depth without an assistant, which is located above, is strictly prohibited.

Note! When the first signs of indisposition appear (dizziness, loss of orientation, drowsiness, nausea, deterioration of health, general weakness, depersonalization, lack of oxygen, breathing problems, other unusual symptoms), you should immediately inform your assistant and leave the mine as soon as possible on your own or with the help of a partner. If the malaise is serious - you should immediately call an ambulance.

Neglecting at least one of these rules can lead to serious injuries, even fatal injuries. If you are afraid of heights or experiencing symptoms of panic, claustrophobia, taking potent drugs, being drunk, feeling weak or feeling not ready to go, then you need to postpone work and find yourself a replacement.

Conclusion

Construction of a well is a difficult and dangerous job, but sometimes such construction is simply necessary. Our instructions will help you cope with this task, and the video in this article will show the process most clearly.