Well drilling rig

The number of people wishing to live in a country house is only growing every year, but one of the main problems that the owners face is the lack of a central water supply. Drilling a water well can solve the problem of water supply, but not all can afford the cost of a brigade’s service for setting up a well. An alternative to the services of specialists may be a custom-made drilling rig for a well with their own hands, which at a price will be several times cheaper, and in the future may be a good additional income.

The choice of installation for drilling

The design of the installation depends on the chosen method of drilling. Small-sized drilling rigs are divided into the following types:

- cable drill;

- auger drilling;

- rotary or hydroburning with a drill.

Depending on the chosen method of drilling, the design and equipment will be completely different.

Shock Drilling Rig

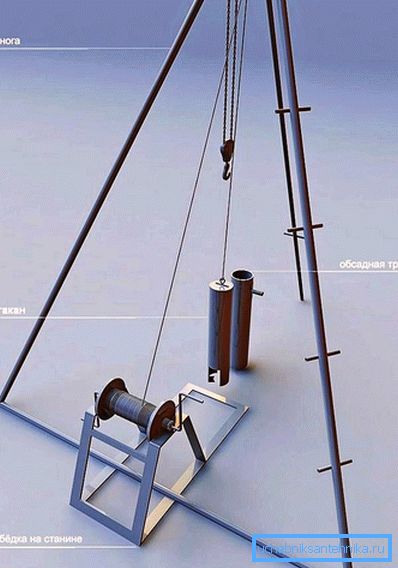

In the implementation of this type of installation is very simple and probably the most inexpensive. The principle of operation of the shock-wire drilling unit is the destruction of the rock with the help of a chisel or a glass, which is discharged into the well. Removal of the destroyed rock from the bottom of the well is carried out with the help of a tin. The design of this installation includes the following elements:

- collapsible metal frame in the form of a tripod with side and winch;

- chisel or driving glass;

- gear motor;

- metal cable or rope;

- shock bar.

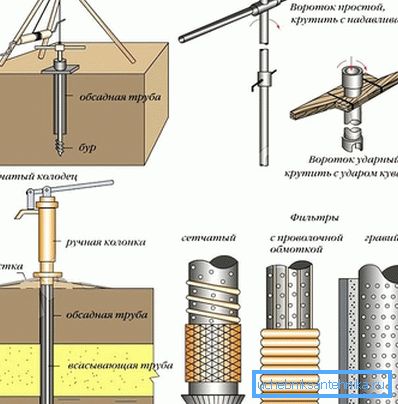

The working tool of the installation is a glass, which is a segment of a thick-walled metal pipe with a length of 1 to 2 m (the longer the projectile, the smoother the borehole) and 8–12 cm in diameter, at the bottom of which the cutting edge of a harder metal is welded.

The cutting edge should have a bevel inside the glass. On top of the glass, an anvil is arranged, which is hit by a drill rod. The weight of the glass for more efficient operation is approximately 80 kg.

The tripod is made of metal pipes. The tower must have a height that will exceed the length of the drill. On top of a tripod, a block is mounted through which a cable or rope is pulled. The cable must have a large margin of safety, and its diameter must be at least 10 mm. A gearmotor is used to raise and lower a drill element. A simpler way is to use a manual gate, such as in a well.

With the help of a winch, the glass rises above the bottom and sharply lowers, since it is during the impact of the glass on the layer of rock that part of it is captured. Inside the glass, the rock is held due to the frictional force.

For the passage of the drilling tool, a drill rod is used deeper, which strikes the anvil of the glass. After several such blows, the glass rises to extract the soil from it, and the operation is repeated.

You can use the glass on dense soils, which include clay particles. For drilling wells in loose rocks are used yolk. At the bottom of the shell there is a valve that opens upon impact, and closes during lifting, thereby keeping the rock in the middle. For the passage of rocks, special bits are used, and the destroyed rock is removed with the help of a yolk.

With the help of percussion drilling on simple soils, it is possible to drill a well up to 100 m, as practice shows, a device of a 40-meter well takes approximately 7 days.

Compact rotary drill

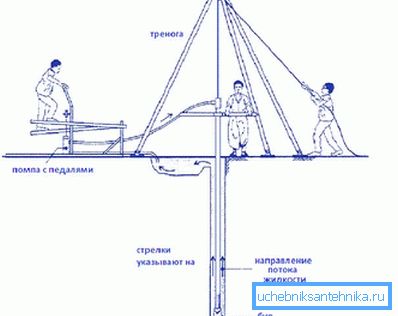

Rotary drilling is one of the most popular methods for well construction. The well is drilled using a special drill pipe, at the end of which a bit is located, the rotation of the pipe can be provided by an electric or gasoline engine.

Removal of the destroyed rock from the bottom is most often carried out with the help of a mud that is fed by a motor-pump through drill pipes to the bottom of a well — it is carried to the surface through the annulus.

The main elements of the design:

- folding frame;

- gear motor;

- swivel;

- motor pump;

- drill rods;

- chisels;

- winch.

The rig is designed for heavy loads, so it must be made of strong steel and be stable. The frame is the part of the design that can be made independently. The swivel is one of the most difficult elements of the installation; the drill rods, the engine reducer and the hose for supplying the flushing fluid are connected to it. It will be very difficult to make independently, it is easier to order at the enterprise or to buy ready.

As drill rods, pipes with a wall thickness of at least 5 mm should be used; the rod length should be approximately 1.5 m. The rods are connected to each other using a tapered thread with rectangular or trapezoidal cutting. This type of thread prevents breaks, and the force is distributed throughout the thickness of the metal.

The electric motor is attached to a special carriage that moves freely along vertical guides. This method of installation allows you to increase the force on the bit and to achieve vertical movement of the drill.

The electric motor must necessarily have a reverse and a warm protection relay, as it will be very warm during the drilling of hard rocks.

The winch can be both manual and electric, the latter option is much easier and accelerates the process of lifting rods.

For drilling wells it is better to use industrial bits, they are more reliable, albeit expensive, but they will be enough for not one hundred meters of drilling. With the help of this installation it is possible to drill wells to a depth of more than 100 m in any rocks.

Auger drill

Installation for auger drilling is one of the simplest and can be performed even from a fishing drill. The drilling process is not labor intensive and consists in removing the soil with the help of a screw. In this way, wells with a depth of up to 10 m and a diameter of up to 100 mm can be obtained.

For the manufacture of such an installation will need a steel pipe with a diameter of 100 mm. On the upper part of the pipe, an external thread is arranged, and at the opposite end of the screw with a diameter of about 20 cm, the number of turns is no more than two. By the end of the auger, cutting knives made of hard steel are welded (on the principle of a fishing drill).

For more convenient rotation of the auger, you need to weld another piece of pipe about 1.5 m and a tee with internal thread. The tee is screwed onto a collapsible bar, which is made 1–1.5 m long. The drilling process can be performed either manually or with an electric motor. If manually drilled, then after every three revolutions of the screw, it must be removed to clean the rock. Repeat the operation until the depth is equal to the length of the rod, after which it needs to be lengthened. The connection of the rods is performed using threaded couplings or studs. If the depth of the well is more than 8 m, the structures need to be mounted on the frame. A winch is used to extract the drill rods and auger.

Video

In this video you can see the work of improvised drilling rigs for the well: