Well drilling technology: a description of the main methods

The technology of drilling wells used to equip the sources of autonomous water supply may be very different. And although most of the techniques can be implemented only by the forces of a professional team equipped with high-tech equipment, they are worth studying.

After reviewing the nuances, you will be able to control the process of performing the work, ensuring the proper quality. Yes, and to save the knowledge of the details will help: at a minimum, imposing on you unnecessary services from an unscrupulous executor will fail.

Basic techniques

Auger drilling

Types of drilling wells are divided depending on how it is destructive effect on the rock. The most important factor in the choice of methods are the properties of the soil, as well as the purpose of the well.

Due to its simplicity, auger technology is considered the most popular:

- The screw is a rod, on one of the ends of which are fixed cutters of high-strength material. Along the length of the rod are screw blades, fixed at a certain angle.

- The penetration of the screw into the rock is done by rotating the axial rod. At the same time, the rock is cut through by the head part without destruction, and rises upward along the blades.

- The use of a screw screw facilitates the extraction of rock repeatedly. At the same time, at depths of up to 10 meters, it is possible to equip wells in a single pass, without removing the drill and flushing the cavity with water.

Note! Screw caps can also be used when drilling horizontal wells. However, in everyday life such a need arises quite rarely.

- Also the advantage of this technique is its availability. Most semi-professional drilling rigs are designed specifically for the auger, and therefore it is very easy to find a brigade.

- The main disadvantage is the difficulty in penetrating dense soils. If the rock lies at the depth, then another principle of drilling must be used.

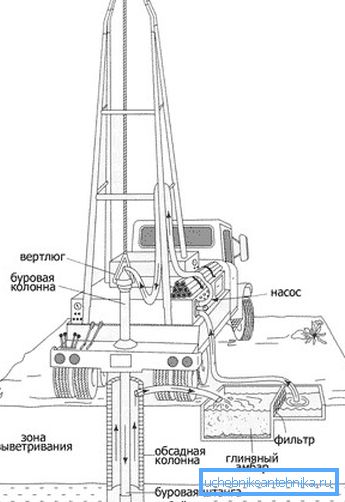

Rotary technique

The process of drilling wells using rotary technology is the most popular in dense substrates:

- The penetration is carried out using a special drill pipe. Inside the tubular part of the shaft is located with a chisel, which provides grinding rocks.

- Since the chisel under the influence of hydraulic loads can develop a sufficiently large force, the rotary method is widely used for the destruction of dense rocks and rock formations.

- There is also practically no depth limit for this principle: even the deepest artesian wells, when there are a sufficient number of rods and casing pipes, are equipped with no effort.

It should be noted that the rotor technique necessarily involves drilling wells by washing with water:

- Inside the drill pipe is placed a hose through which the mud is fed. In this case, the destroyed rock under pressure rises through the annulus to the outside.

- Hydraulic drilling of wells can also be performed by backwashing. When this water is fed into the gap between the casing and the edge of the well, and the pumping of suspended particles of soil through a drill pipe.

Note! The second method is more laborious, however, it allows for better cleaning of the cavity and to get a well with a large flow rate.

Shock technology

Another quite popular technique is the shock.

It belongs to the oldest and most labor-intensive methods of penetration, but the quality in this case is the maximum:

- The basis of the technology is the destruction of the ground mass under the impact.

- Heavy projectile rises to a certain height, and then - dumped on the ground. To lift the slug of the projectile is usually erected tripods up to 3.5 m high, assembled from durable metal pipes.

Note! At the initial stage, the so-called leader drilling of wells is sometimes carried out: a hole is made in the ground by the auger, which plays the role of a guiding chute to discharge the projectile.

- Under the blows of the projectile ground masses are destroyed. The excavation of the crushed rock is carried out with the help of a sheath - a hollow tube with sharpened edges.

- When working on soft and sandy substrates, the projectile is combined with a shell, which can significantly reduce labor costs.

- At the same time, in the process of deepening, water does not enter the cavity of the well, which allows for more accurate opening of aquifers.

- In addition, penetration using the impact method contributes to the compaction of the walls of the well, which has a positive effect on its durability.

The main disadvantage of the shock-rope technique is the high price. Not only does the drilling turn out to be very slow and labor-intensive, so also the casing strings need to be built separately for each aquifer passed.

Independent well development

Choosing a place and time

As we noted above, the described techniques are suitable mainly for industrial implementation. However, with certain skills, you can cope with the task and your own hands. Below we describe what needs to be done in this situation.

First of all, you should decide on the principle possibility of independent drilling:

- Works can be started only when the aquifer lies not deeper than 10-15 meters from the surface.

- This can be determined either by geological surveys (precisely, but rather expensively), or by inspection of existing wells and wells.

- In any case, it is most convenient to choose places for arranging a water source in depressions of the relief. Even a difference of several tens of centimeters can be noticeable.

What shakes time, the best choice is the autumn-winter period, starting in November:

- In the spring and autumn thaw because of the high humidity of the soil is very difficult to ensure the access of equipment to the work site.

- It is also quite a serious problem to determine the exact water level in the well: a large amount of precipitation contributes to the wetting of the entire soil profile.

- Drilling wells in the winter is somewhat complicated by the need to pass the frozen surface layer, but its thickness rarely exceeds 1 m even in the most severe frosts. On the other hand, below is a substrate with quite acceptable performance.

Note! In addition, during winter works, we will have time to pump and equip the source to the beginning of the irrigation season.

Hand drill

A detailed description of the drilling process is as follows:

- On the chosen place we dig a hole in which then we will install a caisson tank or arrange a covered pit.

- Around the drilling site we set up a tripod, which we will use as a support for guide rods.

Note! When the well is being drilled by a motor drill, the tripod is not erected.

- Install auger drill at a selected point and begin to deepen it. Periodically remove the tool and clean the blade from the adhered rock. The removed soil is removed in order to eliminate its shedding into the well bore.

- The deepening is carried out using the rotation of the handles of the drill. It is more convenient to do this together, attaching to the handles extending the “furnace” of a steel pipe 1.5–2 m long.

- After deepening per meter, we begin installation of casing. The diameter is chosen so that the drill freely passes through the lumen of the pipe. Usually it is not difficult, since during the rotation the auger destroys the walls, leaving a sufficiently large gap.

- The connection of parts of the casing is carried out either by using a thread or by welding. To simplify the process, it is best to use polyethylene pipes, then an inexpensive plastic soldering iron can be used for welding.

- Drilling is carried out until the aquifer is completely crossed. If you stop at the first signs of the appearance of water - the flow rate will be understated very much.

- After completion of drilling, remove the auger part from the cavity. The instruction recommends that before starting operation, clean the lower part of the well, either using the wire on the cable or by washing with a submersible pump.

Conclusion

As you can see, the drilling of wells for heat and water can be carried out using a variety of methods. However, some of them can be implemented on their own, while others require the use of heavy construction equipment and professional equipment. For more information about the nuances of the technologies used will help the video in this article.