Well drilling tool - variations and usage patterns

If you decide to break your own well, then for these purposes you will need certain equipment and tools. Of course, the easiest way is to hire professional drillers who have everything you need. But you can cope with the task yourself.

In this article, illustrated photo, we will discuss the tools that should be used if you drill a hole with your own hands.

Basic drilling accessories

Note that some tools can be made independently, if their price in the store does not suit you. Detailed instructions on how to make some equipment, as well as how to use it, are available on our website..

Today, drilling rigs are often used for drilling wells, but their use is justified only if you need to break through to a greater depth.

Among other tools, it is worth noting the cones for drilling wells, which not only make their way to a certain depth, but also carry out the flushing of the well in parallel. This type of tool is recommended for use on rocky soils.

Expanders for drilling wells are used in case you need to make not only deep, but also a large diameter barrel under the pipe.

Now let's consider some parts of the equipment and tools that are in demand when drilling wells.

Drilling spoon

This tool is used when working on certain soils:

- clayey;

- sandy wet;

- loamy;

- sands, which include pebbles, gravel.

The peculiarity of the spoon is that it is characterized by two types of movement:

- progressive;

- rotational.

A drilling spoon is a special cylinder consisting of the following parts:

- threaded head;

- the diameter of the thread corresponds to the diameter of the rod on which it is screwed;

- cutting edge;

- case - with a longitudinal incision;

- one edge is curved inward;

- the second is sharpened and serves as a blade.

The soil during drilling gets inside the cylinder and accumulates there before removing it from the barrel.

Council Spoons have a different diameter and are selected depending on what kind of pipe diameter you plan to install - 70, 140 or 198 millimeters. Choosing a particular spoon, remember that the diameter should be 10 millimeters smaller than the diameter of the casing.

Spiral Bore and Coils

This type of equipment is used if it is necessary to punch a well in soils of the following type:

- clayey;

- loamy;

- sand with gravel or slag.

The essence of the coil device is as follows:

- threaded head for connecting with a rod;

- spiral coil;

- a special blade is provided at the end of the coil.

During rotation, the coil slowly bites into the soil, the blade begins to cut off the ground, which rises up the coils. The soil accumulates on the coils and withdrawn from them after the coil is removed.

Known to many women

The purpose of this equipment is to raise the ground to the surface.

It is recommended to apply on soils of two types:

- loose;

- loose.

Council You can make tools such as a shell or a bore yourself, having the necessary strong metal. Or order the production in the metal workshop, which in any case will cost you less than buying tools in the store.

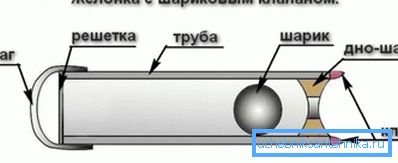

The wellbore is a device of the following type:

- a piece of steel pipe;

- pipe diameter depends on the estimated size of the well;

- the cutting shoe is provided below - a ring made of hardened steel and a blade that cuts the ground;

- there is also a valve at the bottom that ensures the fixation of the soil inside the pipe;

- after raising the zhelonka to the surface, the valve opens and the ground is poured out.

Council When working on quicksand it is best to use a hip or disc-shaped flat valve.

Rods for rotation or shock

This type of tool is a special sucker rod tube, which can tolerate even increased loads, including:

- compression;

- bend;

- stretching;

- twisting.

Also instead of pipes can be used such products as:

- square steel bars;

- steel rods of circular cross section;

- water pipes with a reinforced wall.

Rotary drilling tools

Let us consider some more tools that are used in the rotational method of drilling wells, which implies:

- rotational motion;

- necessary pressure on the ground.

For this type of drilling, a special swivel is used, to which are also connected:

- rotor;

- mud pump;

- hose.

Council If you want to ensure the rotation of the bit in the mine, then in this case, you will need a screw downhole motors for drilling wells.

In such equipment, a large role is assigned to the rotors - it is they who transmit the rotation to the entire column. For this, a winch is used, and the rotational speed directly depends on the transmission mechanisms. Although there are rotors that can work individually, that is, without using a winch.

The essence of the swivel is that it provides the connection:

- drill string;

- talevy system.

As a result of such a connection, the column is rotated and the supply of the so-called washing solution is carried out.

A special adapter is mounted below, which ensures a reliable connection of the entire device with other tools that perform drilling.

For supplying the washing solution, a conventional flexible hose is used, by means of which the fluid is pumped into the pipes. The fluid supply is carried out under pressure, for which a special pump is used.

Council To prevent pressure fluctuations during the supply of liquid or at least to minimize its probability, it is recommended to use compensators. They are mounted directly on the pump and soften hydraulic shocks.

In conclusion

This is the main set of tools through which you can drill a well. Large installations are equipped with diesel, electric and gas turbine type drives.

In the presented video in this article you will find additional information on this topic.