Well equipment required - useful information

So, the well on your site has been successfully drilled in the most suitable place for this, in compliance with all the conditions and requirements for such structures. The necessary measures for pumping the well have also been completed, the next step is the determination of the necessary equipment so that not only water flows, but a cleaning system is also provided. We will tell you about this in our article.

Purpose of well equipment

To begin with, how well equipment is divided according to its functional purpose, or rather, how many fundamental elements are included in its composition.

Cleaning system

Filtering water in the so-called sand wells is an absolutely necessary measure, since it not only improves the quality of the water taken from the depth, but also allows the pump to work without breakdowns and deterioration.

Filtering occurs:

- At a primitive level, at the bottom of the well, through the filter which is equipped with the first casing, lowered to the very depth.

- A more subtle purification of water is carried out on the surface, while passing through special filters.

The selection of filters is carried out individually, according to the initial analysis of water from a particular well and the wishes of the owner regarding its quality.

In any case, the water filtration system should provide the following tasks:

- Removal of impurities dissolved in water (manganese and iron are dangerous in large volumes for humans) and gases (hydrogen sulfide).

- Water softening (stiffening stabilization).

- Fine micro - and ultrafiltration.

Note! Sandy are wells drilled to a depth of 15 to 80 m in the region of the first three sandy aquifers: upper water, groundwater and interbedded waters.

The filtering equipment for the artesian well, unlike the sand one, is practically not used. Artesian water is usually crystal clear and can be used even for drinking without additional purification. Of course, a thorough preliminary analysis of water from an artesian well, after complete pumping, will not be superfluous.

Water supply to the surface

For lifting water using a variety of pumping equipment for wells.

- If we are dealing with wells with a depth of 8 meters or more, in such cases deep-well submersible pumps are used. Such units operate in conditions of partial or complete immersion in water. In this regard, the material of which the pump casing is made is of paramount importance; ideally, it is stainless steel.

- If the distance to the water level in the well is up to 8 meters, it is possible to use self-priming surface pumps. Such pumps are afraid of moisture ingress, so they should be protected from precipitation under sheds and also insulated in the cold period of the year. The most convenient will be the location of the surface pump in a warm technical room of the house or caisson (pit) near the well.

Tip! Experts do not recommend the use of vibration pumps in wells, as they provoke silting or zapocheochivanie bottom of the well.

The choice of the type of pump and its technical characteristics determine:

- Well productivity (volume of water inflow over time).

- Maximum water consumption in the house.

Note! The diameter of the purchased submersible pump should correspond to the dimensions of the well casing. The pump must be immersed in the well without difficulty.

For uninterrupted water supply to all points of parsing in the home and in the territory, the autonomous water supply system is equipped with a storage tank. Since we need potable quality water, storage tanks are made of food grade plastic or stainless steel.

Despite the fact that the price of the latter material is much higher, the device of the stainless tank is more preferable. The larger the storage tank in terms of volume, the greater the supply of water in case of power outages, but its weight and overall dimensions are also greater.

The storage tank is placed, as a rule, in the attic or in the basement, so you should not forget about its good insulation. To regulate the water level in the tank and automatically turn on and off, use the end float switch.

Pumping stations

In order to avoid the location of a huge, heavy storage tank, and even fiddle with its insulation, modern homeowners prefer to equip the water system with a pump station.

Her work automatically maintain and, if necessary, adjust the pressure in the system.

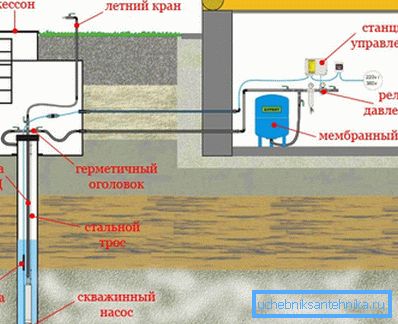

The well pumping station includes an automation system that manages:

- Turn on the pump when the pressure in the system.

- Turning off the unit when dialing a user-defined maximum.

In addition, the system "well - pumping station" includes:

- Directly deep well pump.

- Power supply network (cables, circuit breakers, etc.).

- Borehole pipeline.

- Internal wiring of pipelines with connection of locking and dismounting devices.

- Device for lowering - lifting the pump.

- Stainless steel cable attached to a special mounting ear on the pump body.

- Pressure gauge.

- Pressure switch.

- A check valve is installed above the pump to avoid returning water to the well.

- The hydroaccumulative tank, absolutely small, with a volume from 25 to 50 liters. It is easy to place in a convenient place for you.

- Caisson - pit, located near the wellhead.

From the wall of the caisson to the premises of the pumping station (in the house) it is necessary to dig a trench for laying the conduit and electrical cables. The depth of the trench should exceed the depth of soil freezing in the area.

Communications necessarily warmed. Entering the house through a special window in the foundation left during construction, followed by a thorough sealing.

Wellhead

Simple, but very important is the third group - wellhead equipment. The wellhead is the place where the well intersects the ground. By wellhead equipment is meant a device, the so-called tip, for the hermetic closure of a well exit to the surface.

The top of the casing must be protected from contact with:

- Foreign objects.

- Water from the soil surface.

- Dirt and sand.

At the same time, on the tip, passing through its structure, a cable supporting the pump and transitional fittings for the conduit are mounted. In principle, the caisson also relates to the equipment of the wellhead. These are usually fairly simple designs, often self-made.

Now more specific instructions on the equipment well with their own hands.

Perform, for example, simple equipment wells in the country for seasonal use.

- First, we attach a pipe, a cable holder and an electrical cable to the pump. All three tracks are fastened together with tape or plastic clamps in increments of a meter.

- Then very carefully lower the pump into the well.

- Now the wellhead equipment. The usual option for giving is to install a metal box over the well, well secured, no matter what the pump is pulled off and so on.

Note! For the cold period of the year, remove the pump from the well or lift it up, be sure to warm the top of the well.

More difficult and serious is the equipment of injection wells for oil production, but read about it in our other articles.

Conclusion

Now you know what equipment you need for a well and how many groups it is divided into. In the assembly, such a construction can occupy 2-3 square meters, with ease of use - keep this in mind at the time of planning your residential house, so that in the future there will be no questions, but where to put the water tank.

In the presented video in this article you will find additional information on this topic.