Well filter - selection features

The design and quality of the filter play a crucial role in the durability of the well, as well as in the quality and quantity of water entering the water supply several years after the construction of the system. Therefore, the choice of this element must be approached very responsibly. Next, we consider in which cases, and which filters for wells are used most often.

First of all, it is necessary to understand that the water filtration zone, as well as the production pipe, are usually non-replaceable structural elements. Accordingly, the service life of this device determines the service life of the system as a whole. However, often the materials from which the filter is made and the quality of its manufacture are used as a certain reserve of competitive price reduction of the cost of services of some organizations involved in drilling.

The fact is that even the cheapest product will be able to work for several years, but what will happen to the system in the future, such companies are not interested. Therefore, before using the services of an organization, it is necessary to understand what the filters for a well are.

Why do you need a filter

As a rule, wells allow to extract water from horizons containing loose or unstable rocks, which include:

- Pebbles;

- Sands;

- Fractured rocks.

As a result, the water entering the production string contains various mechanical impurities. The number and size of these inclusions are unstable and it is almost impossible to predict them. If these inclusions are not delayed at the entrance to the pipe, then with time the trunk will be filled with them so that water will no longer flow into it.

In addition, most submersible pumps are simply not designed for pumping water with mechanical impurities. Therefore, if you do not use the filter on the well, then very quickly the devices fail.

It is to prevent any mechanical impurities from entering the wells that the filter column is performed in the well.

Tip! For sand wells, it is desirable to surround the filter with fine gravel, which will hold up most of the mechanical impurities on the approach to the perforated pipe.

Types of filters

For artesian wells

It is necessary to choose the design of the filter in accordance with the geological characteristics of the aquifer from which it is planned to extract water (see also the article The Filter Screen for Wells — Features of the Site).

In artesian wells, the trunk is generally left open. This is due to the fact that such wells, as a rule, give a good pressure, as a result of which the water rises to a considerable height.

Therefore, the submersible pump is also located at a decent distance from the water intake. In addition, fine-grained mechanical impurities in the limestone almost never occur.

In wells with unstable pebble and limestone aquifer, in which there is not too high pressure, the pump is installed close enough to the water intake. Therefore, the use of a filter in the well is necessary.

Note! The downhole filter performs a fairly coarse water treatment to protect the equipment. For more thorough cleaning, you need to use additional devices, for example, you can install a main filter for wells.

In such cases, too thin purification of water is not required, since small impurities are also absent. Therefore, as the filter is used simply a segment of a perforated pipe. This is a common service pipe with a lot of holes of small diameter.

If there is no sand in the aquifer, then this design is enough for the well to last a very long time.

For wells on sand

It is much more difficult to find a filter for a hole in the sand. Aquifer sandy horizons pose a lot of problems for drillers and well owners. However, such wells are the most common, as they are much easier and cheaper to equip than artesian wells.

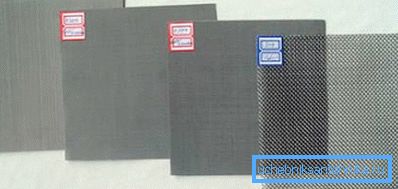

For water purification, special mesh cleaning systems are made. The life of the well depends on their quality as well as on the quality of their installation.

How does the filter

Filters on the well in most cases have a fairly simple device, so the defining moment of their durability is the quality of the device, as well as the quality of materials.

So, the design includes the following elements:

- Perforated base;

- Frame;

- Filter layer

By the type of filtering layer, devices are of several types:

- Mesh is the most common type;

- Wire or frame-rod;

- Combined, including with gravel packing.

Perforation Types

At the heart of any filter is a perforated tube.

By the type of holes, it can be:

- Perforated - holes can be staggered or in rows. The diameter of the holes is 10-20 mm.

- Slit - such a base has a better bandwidth, but it is less durable in bending. Therefore, when applying gaps, it is necessary to provide stiffeners, i.e. plots without gaps.

Tip! If the filter is selected for a well with a flow rate of up to 5 cubic meters per hour, the type of perforation does not matter. The main thing is that the perforation is performed according to the rules and does not violate the resistance of the pipe to mechanical loads.

Pipe material

In terms of strength and durability, the best option would be a stainless filter base. However, it is advisable to use a metal pipe only if the production string is also made of steel. If the column is plastic, then, accordingly, the base should be plastic.

This is due to the fact that pipes of different materials are almost impossible to hermetically connect with each other. A loss of tightness of the pipe, it is, in fact, the loss of the entire well.

Frame

Regardless of the type and material of the base, the downhole filter should not fit tightly to it. Otherwise, only those areas that are located opposite the holes will function.

Poet between the grid and the base perform the frame, which is of two types:

- Wire wrapped on the base with a step of 1.5 - 2 cm. This option is relevant for mesh products.

- Vertically located rods - usually used for filters made in the form of a spiral of a wedge-shaped wire.

Filtering surface

There are two main types of filter surfaces:

- Grid - the diameter of the cells is selected in accordance with the characteristics of the soil;

- Special wedge-shaped wire, spiral wound on a frame.

Each type of construction has certain advantages and disadvantages, however, it does not make sense to list them, since for the most part they are related to the production technology.

Gravel filter

There is another type of water treatment system, which should be mentioned separately - this is a gravel filter. This design is the simplest, however, its quality is no worse than the above-described structures. However, such a filter can be used only in clay and shallow wells.

Instructions for the manufacture of such a filter is as follows:

- If it is decided to use this type of treatment, then the well must be drilled larger than the casing.

- Then you need to carefully calibrate the gravel. Its fractions should have approximately one size, 5-10 times the size of the rock particles.

- Next, a casing pipe is installed and gravel is poured. The thickness of the dusting should be at least 50 mm.

As a rule, such a filter is carried out by drillers with their own hands in the process of producing a well.

Conclusion

Having understood the features of well filters for water, it will not be difficult to determine the choice of its type. It is necessary to ensure that the product is made of high quality, in accordance with the above technology. In addition, the quality indicator in some measure is the price of the device, so you should not “chase” for cheapness.

Additional information on this topic can be obtained from the video in this article.