Well mouth. arrangement

To understand what is, for example, the neck of the well k06, we need to understand what the whole structure consists of, and only then can we isolate its upper part. Although such devices can be made of brick and even plastic, we still pay attention to the concrete products - they are most common and, moreover, more convenient and simple during installation.

This is what the conversation below will go on, and in addition, as a supplement, we will show you a thematic video in this article.

More about wells

Note. In our case, we will focus on manholes, which are designed for water intake (not water intake), sewage, power supply and communications, as well as for gas pipelines.

What is a neck

- According to GOST 8020-90, the wells' necks are made of heavy (reinforced) concrete, with a grade not lower than B22.5 (M300), the permeability of which is W2, and frost resistance F. Also, for mounting the metal frame, fittings of type AI, A- III or Bp-I. However, according to the same GOST, other concrete elements must be made from similar materials.

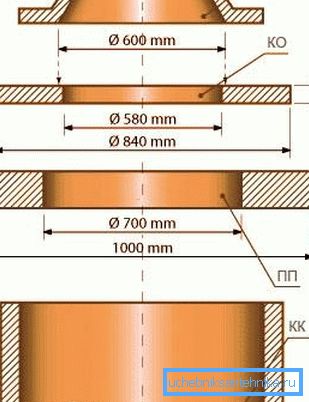

- In some cases, wells are installed without a neck, then the shaft rings (QC) rise to the surface, where they are installed on the floor plate (PP), the casing ring, which, in fact, will be the neck (KO) and the metal (concrete) hatch (LC ). In these cases, all requirements of GOST 8020-90 should be fulfilled, since sometimes utilities, wanting to save money on materials, force the builder to make casing rings of cement-sand mortar or brick with their own hands, as a result of which the structure as a whole suffers.

- The fact is that factory KOs reduce the load on the structure by about 10 times, when motor transport passes over it, evenly distributing the total mass over all points. But in situations where the casing ring is self-made, it does not have the necessary strength and begins to collapse under the influence of moisture and mechanical loads. As a result, in the absence of a uniform distribution, the floor slab suffers, then the neck or concrete casing ring and passing vehicles can simply fall into the mine.

- In addition, the neck can be made of brick (so its price will be less), but in such cases it is better not to do this on busy roads and loading and unloading platforms, that is, in those places where there is a possibility of a large mechanical load. As a rule, such constructions are placed in places where the movement of vehicles is reduced, or it is not there at all. However, the floor slab, the casing ring and the hatch must comply with Gosstandart, otherwise the arrangement will be at risk of destruction.

| Marking | Outer diameter in mm | Internal diameter in mm | Wall thickness in mm | Height in mm | Mass in t | Volume in m3 | Landmarks. The cost in rubles |

| COP 7-3 | 840 | 700 | 70 | 200 | 0.13 | 0.05 | 873 |

| COP 7-6 | 840 | 700 | 70 | 590 | 0.25 | 0.1 | 1215 |

| COP 7-9 | 840 | 700 | 70 | 890 | 0.38 | 0.15 | 1560 |

| COP 10-3 | 1160 | 1000 | 80 | 290 | 0.2 | 0.1 | 1260 |

| COP 10-6 | 1160 | 1000 | 80 | 590 | 0.4 | 0.16 | 1485 |

| KS 10-9 p / g | 1160 | 1000 | 80 | 890 | 0.6 | 0.23 | 1770 |

| COP 10-9 | 1160 | 1000 | 80 | 890 | 0.55 | 0.23 | 1640 |

| COP 15-3 | 1680 | 1500 | 90 | 290 | 0.32 | 0.14 | 2485 |

| COP 15-6 | 1680 | 1500 | 90 | 590 | 0.67 | 0.26 | 2860 |

| COP 15-9 | 1680 | 1000 | 90 | 890 | 0.96 | 0.4 | 3040 |

| COP 20-6 | 2200 | 2000 | 200 | 590 | 0.98 | 0.39 | 4680 |

| COP 20-9 | 2200 | 2000 | 100 | 890 | 1.47 | 0.59 | 5540 |

Table of some of the types of through concrete rings

How to make a sewer well

So, as you understand, the part of the well, called the throat, is the same through concrete ring, only of a smaller diameter than the mine production rings. Only more often they have a small height and can serve as the same casing ring and on top of them you no longer need to install floor slabs, but immediately install the hatch. A slab with a side or center hole is installed, as a rule, on top of a shaft.

If we talk about the sequence of work, the whole process begins with the digging of the mine, where the well will be settled. In these cases, the trunk is almost never very deep, on average, it can be from one and a half to three meters, although in urban environments the storage and filtration devices can be much deeper.

To install QC, a cushion is needed, which is usually made of sand or rubble, but if the device is supposed to be equipped as an observation device, then it is necessary to concrete the bottom for it or put an RC slab there.

After that, KK is lowered into the mine, but they should be planted on a cement-sand mortar in order to exclude the penetration of groundwater or, in any case, make it minimal. After that, again, a cement slab is placed on the cement mortar, which should correspond to the size of the main QC. And now, depending on the need, you will choose the height of the neck or KO.

Although, taking into account the situation that this is done on your site and the movement of vehicles, and therefore loads, is not expected there, KOs can be made of any height from brickwork - this can hardly be regarded as a violation of safety precautions.

After that, you will only have to install a hatch, which you can also make yourself from wood or concrete, although it is much better to take a factory metal product.

In addition, when planning the sewage system, one should not forget that the nearest well should be no more than 12 meters from the house, but no closer than 3 meters, so as not to have a destructive effect on the foundation of the building. When inserting pipes into the rings of the entrance (the distance between the walls of the pipe and QC) should be sealed with cement mortar or tile adhesive for sealing.

Note. All sewage wells can be divided into categories and it is filtration, inspection, differential, rotary and accumulative, where each is of no small importance. However, the system can be cleaned from each of them, since in fact, each is a kind of septic tank and there is a differential pipe.

Conclusion

As you understand, the instruction for the manufacture (installation) of such devices does not constitute anything too complicated. But here it should be borne in mind that even the installation of the neck, not to mention the main rings, is extremely difficult in the physical sense, and this requires either a crane or a crew of workers. Virtually all factory QA and most of the KOs are equipped with mounting ears for hooking the lines.