Well piping: features of construction and operation

If you are interested in what is better - a well or a water supply system, then surely your home is not able to connect to the centralized water supply system. As a rule, the need for an autonomous source of water supply is in demand in the countryside, away from large settlements.

Water supply system in the country from a well is one of the most common types of autonomous water supply.

This method is characterized by a number of obvious advantages, including:

- economical operation of the system;

- low cost;

- practically inexhaustible supply of water;

- high mechanical and chemical purity of water.

- long life of the well, up to 50 years.

Features of the arrangement of downhole systems of water supply

How is the installation of the water supply system at the dacha from the well, what materials are needed for this and what are the budgets for the project? We will answer these and similar questions in this article. As an example, consider the case of the construction of a downhole pipeline using a submersible pump..

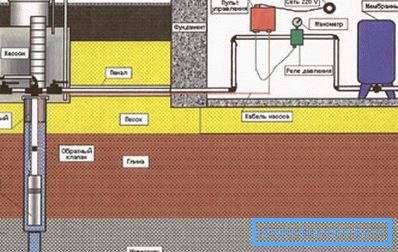

The standard autonomous borehole water supply system consists of the following elements:

- well with integrated submersible pump and other equipment;

- caisson (well service well);

- an underground pipeline connecting the pump to the internal water supply system;

- inter-house pipeline system;

- filter system;

- complex of automatic control of parameters of a given pressure;

- hydroaccumulative tank;

- stop valves;

- water heater.

Types of wells

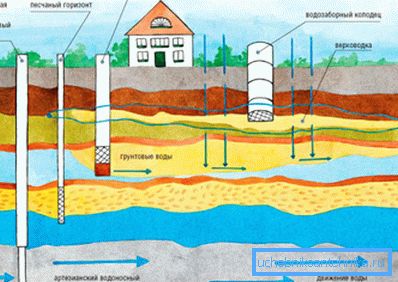

Modern wells involved in water supply systems are divided into two main types: sand and artesian.

- Sand wells are drilled to a depth of 30 meters and allow to extract up to 1.5 cubic meters of water per hour.

But it is necessary to understand that such flaws are characterized by some drawbacks, and in the first place it is the probability of silting the aquifer. Especially, wells at sites intended for seasonal use are susceptible to siltation.

- An artesian well is drilled to a depth of 70 meters or more, providing water up to 10 cubic meters per hour.

Water extracted from such a deep country house with its own hands is characterized by a high level of mineralization, and therefore requires additional treatment. For this reason, in addition to the submersible pump, sophisticated filtration systems are used, providing comprehensive water purification to the technical or drinking state.

Selection of filtration equipment is complicated by the different composition of water produced in different areas. Therefore, a chemical analysis may be required to make an optimal decision.

The operation of a full-fledged artesian well at a dacha or near a country house is complicated by the need to use a filtration system, from which it is necessary to drain water for the time of seasonal preservation of the object.

Types of assistive devices

The current scheme of water supply from the well provides for the need to use a number of auxiliary devices.

These devices ensure the efficiency and durability of the system as a whole and guarantee the high quality of the water produced.

- Casing pipe is an essential attribute of the well. The casing pipe is selected for reasons of compliance with the diameter of the section and other sizes.

- A cap is an auxiliary device that is mounted with your own hands in the upper part of the casing and serves to prevent debris and foreign objects from entering the well.

- Pipe - a means necessary to supply water to the surface. The pipe is mounted on the top cap.

- A cable is an essential attribute of any well, the water supply from which is carried out using a submersible pump. The cable is attached to the bottom of the top cap for a special eyebolt. At the opposite end of the cable is fixed submersible pump, whose position can be adjusted by raising or lowering the cable.

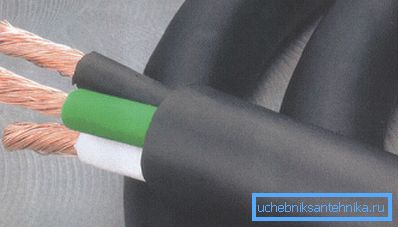

- A power cable is used to supply power from an electrical source at the top to a submersible pump.

- A submersible centrifugal pump is a device designed to pump water. The parameters of the device depend on such factors as the height of the water rise and the planned marginal water intake.

Before installation of equipment, it is necessary to consider that the pump weighs a lot. In addition, the weight of the pump must add the weight of several tens of meters of power cable and hose. Since it is forbidden to pull the pump by the hose or by the cable, a metal cable is used that is wound on the winch, while the hose and cable are rotated on special reels.

Important: The fixing of pumping equipment must be particularly reliable, since a breakage will lead to the flooding of the pump and the need to drill a new well.

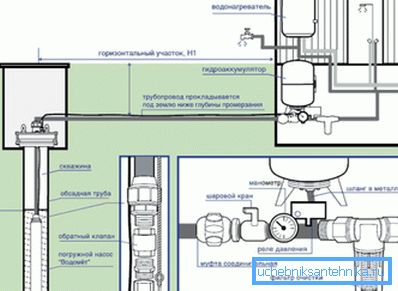

Installation rules for the external part of the water supply system

The main component of the external part of the water supply system is the pipeline through which water obtained from the well will be transported. The modern pipeline is made of polyethylene pipes.

This solution guarantees a number of obvious advantages, including:

- low price, in comparison with the pipes made of metal;

- maximum resistance to the appearance of corrosion, as polyethylene does not rust;

- durability of the structure, since the pipeline in the ground can last more than 50 years;

- lack of taste in water, as polyethylene, unlike metal, does not have a specific smell and taste;

- low hydraulic resistance, unchanged even with long-term pipeline operation.

Pipeline installation for seasonal operation

Installation of water supply for water supply from the well is carried out taking into account a number of rules. For example, if a cottage or a country house is used exclusively for use in the warmer months, the water supply system is not necessarily deepened.

In extreme cases, pipes can be laid at a depth of 1 meter. In this case, in the autumn it is necessary to drain all the water without residue in order to prevent damage to the pipeline in winter.

To be able to ensure complete discharge of water, the pipeline is installed with a slight slope in the direction of the drain valve wells. In order to simplify the conduction of water discharge, an electric valve is mounted on the pipe section in the well, at a distance of several meters from the surface.

Such laying of the pipeline will completely eliminate the possibility of breakdown of the autonomous water supply system.

Pipeline installation for all-season operation

If a country house or cottage is operated year-round, the pipeline must be laid 20-30 cm below the depth of soil freezing. As a rule, the parameters of soil freezing depend on both the minimum winter temperature and the type of soil on the site.

Each region is characterized by its own levels of soil freezing.

For example, in Moscow and in the Moscow region, these parameters are:

- for loam and clay 1.35 m;

- for soils with a fine sand content of 1.64 m;

- for soils with a content of medium and large sands 1.76 m;

- for stony ground 2 m.

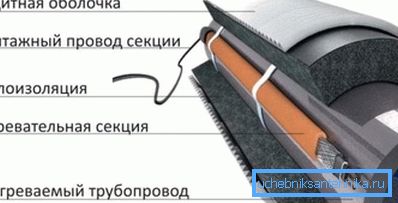

Taking into account the fact that the laying of pipes at a depth of about 2 meters is associated with significant labor costs, several more or less effective ways to install plastic pipes to a lesser depth were developed. First of all, it should be noted the method of laying pipes with insulation and their installation with a special heating cable.

It is no secret that there are many materials, the degree of thermal conductivity of which is an order of magnitude less than the degree of thermal conductivity of the soil. As a result, you can dig not a two-meter trench, but a meter one.

Before laying the pipeline, it will be possible to wrap insulation with, for example, extruded polystyrene and cover it with earth. Now your cold water will not be scary!

The advantage of this solution is also in the fact that modern heaters are hydrophobic, which means that you will not have to spend money on waterproofing equipment. But, if the frosts in the cold season reach critical levels, one heater may not be enough. In this case, the insulating material is used in combination with the heating cable.

The cable is wrapped around or along the pipe, and then wrapped with insulation. In normal mode, the cable is not used, but with a sharp decrease in the ambient temperature, the heater is connected to the network.

The heating cable is not able to melt plastic, but it can heat water along the entire length of the pipe a few degrees above zero. This method has found wide application in areas where the groundwater level is high, and therefore it is impossible to lay a pipeline deeper than the level of soil freezing.

Important: If the heating of the pipes was not connected in a timely manner and the pipes were frozen, it would not be possible to warm them until the spring, since the cable capacity would not be enough for this.

Selecting and applying filters

The installation scheme of the water supply system from the well suggests the following order of the elements: a submersible pump, a drain valve behind it, and then a certain number of filters.

The main criterion for the selection of filters is the quality of produced water. As a result, water with a high content of solids implies the use of one type of filter, while water with a high level of salinity implies the need for other filter elements.

At artesian wells, a filter is applied that delays such impurities as iron and lime. If you intend to use a shallow well on the sand, you will need a system of filters for mechanical cleaning. In any case, a well-designed filtering system provides high quality water without impurities.

Installation of filters is considered correct if the system is efficient and there is easy access to the filter elements for their maintenance and replacement.

Important: Installation of filters to the hydroaccumulator is necessary not only to ensure optimal consumer water quality, but also to eliminate the possibility of clogging of the elements of the water supply system. As a result, a well-designed and constructed filtering system results in an increase in the resource life of the autonomous water supply.

Automatic control system

In order for the water supply system from the well with its own hands built to work optimally, it must be equipped with a complex of automatic control.

This solution guarantees the following benefits:

- Reducing the number of on and off electromechanical equipment (in particular the pump motor);

- Ensuring a stable pressure in the water supply system in accordance with the specified parameters;

- Preventing the occurrence of water hammering and, as a consequence, maximum safety of the water pipeline operation

What is automation in the water supply system, and what are the features of its functioning?

The automation complex is a relay system consisting of an idling relay and a pressure relay. These elements are associated with a submersible pump. When the pressure in the pipeline drops below the preset parameters, the relay is activated and the pump motor turns on. If the water pressure reaches the limit, the relay opens and the engine stops until the parameters return to normal.

Water consumption in a small house is small. Consequently, every turn on the tap or flush the toilet will cause the pump to turn on, and then to turn it off. To prevent frequent switching on and off of the engine, in addition to the automatic regulation system, a hydroaccumulator (receiver) is used.

Accumulator

A receiver is a container that is divided into two parts by a dense membrane. One part is connected to the water supply system and is filled with water, while the other part is filled with air (pressure up to 2 atmospheres).

The principle of the receiver is as follows: water pushes the membrane as it fills, which leads to an increase in pressure in the air tank. When the pressure from 2 atmospheres increases to three, the engine stops.

Unlike an electronic relay, the hydroaccumulator does not respond to minor fluctuations in water pressure, therefore, the number of on-off cycles of the engine can be minimized.

Conclusion

If there is no access to a centralized water supply at the dacha, there is no need to choose a well or a central water supply system. On the other hand, well-equipped well, you get access to high quality water. You can get more interesting and useful information by watching the video in this article.