Well pump aquarius

One of the main structural elements of a well is its lifting equipment - a pump. Reliability and durability of the water supply system operation depends on the correctness of the selected pump. The market of pumping equipment is represented by a wide range of different models from different manufacturers. Among this diversity, the well pump Aquarius is very popular among consumers due to a reasonable price-quality ratio.

Design

The device of the Aquarius pump is simple, it has a simple structure and consists of:

- AC motor that operates on 220 V mains;

- pump part having a monoblock design;

- remote control boxes to which the power cord is connected.

The electric motor includes a rotor, a stator and two ball bearings rotating in an oil medium. Automation, which monitors and controls the operation of the pump motor, is produced by the German company Thermik. It provides reliable protection in case of emergency situations (device overheating).

The pumping part consists of a stainless steel body in which there is a drive shaft with impellers, vanes and guide rings. In the upper part of the housing there is a cap with internal thread that holds all parts and closes the pump. The cover has two eyes for fastening the retaining cable.

When the device is turned on, the rotating impellers create a centrifugal force that pumps the water that fills the internal cavity of the pump part. The pump is designed to work in a fully submerged state. Currently available products with a capacity of up to 12 m3/ h and head up to 200 m, with a minimum diameter of 100 mm.

Installation and connection

Before the pump is lowered into the well, it must be prepared. Wiring it is very simple:

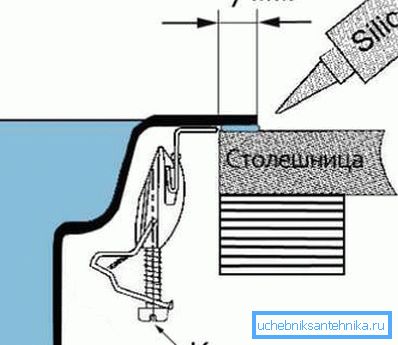

- Connect the pressure hose or pipeline with a diameter of at least 20 mm using fittings. Be sure to install a check valve - this can be done by cutting it into the pipe at a distance of about 1 m from the pump, or it can be installed directly into the inlet of the device, the second option is preferable. It is recommended to use a check valve with a brass seat.

- Fasten the cable, passing it through the special eyelets on the cover body. It is strictly forbidden to lower and raise the pump by the cable; this is done with a cable and a pipe. For reliability and ease of descent of the device, it is better to attach the cable to the lifting pipe with clamps.

- The pump in the assembled state is carefully lowered into the well, it must be ensured that the hose and cable are not tensioned. The device is fixed at the calculated depth using a cable.

To connect the device to the electrical network, you must use a three-core cable that provides reliable grounding.

Operation and maintenance

Pump Aquarius belongs to the class of household submersible pumps, that is, it is used for domestic needs for water intake from wells, open reservoirs, wells. In order for it to work smoothly for a long time, you need to follow the following rules during operation:

- The temperature of the pumped water should not exceed 35 ° C, and mineralization should not exceed 1500 g / m3.

- The remote control must be installed in a dry room, eliminating the ingress of water.

- During operation, the device should be completely immersed in water, its lower part should not fall below 40 cm from the bottom.

- The first start should be carried out not earlier than 5–10 minutes after the pump is completely lowered into the water.

- It is strictly not recommended to pump highly contaminated water with a high content of sand, also alkaline and acid liquids.

- If the pump is not to be operated for a long time, it must be removed from the well and stored in a dry room, after having previously been smeared on unpainted surfaces with an anti-corrosion lubricant.

In addition to compliance with all recommendations, you need to regularly, at an interval of once every two years, carry out routine maintenance of the pump and timely repair of components:

- Inspect bearings and O-rings for grease presence and integrity, lubricate if necessary. It is not allowed to use engine oil or grease as a lubricant; special petroleum jelly is intended for this. If the bearings are worn, they should be replaced.

- Check the oil level in the motor housing; use liquid petroleum jelly as a lubricant; if necessary, top up it.

- Check the tightness of the glands and clean the filter from all sorts of dirt.

During disassembly, care must be taken not to damage the electric cable coupling, which eventually becomes brittle. If you follow all these recommendations, the pump Aquarius will serve you for at least 10 years, the minimum output is 10,000 hours.

Video

From the videos provided, you will learn more about the downhole pump: