Well pumping station: device, varieties, installation

For well servicing, various pumping equipment is used: this is also surface equipment with accumulators or storage tanks, and submersible devices, and mechanical pumps.

We want to tell about pumping stations for wells, which belong to surface water supply systems.

Pumping station

Device

In general, a typical pumping station is a system consisting of the following basic elements:

- Hydroaccumulator. This is a tank into which water is pumped to a certain pressure, allowing the system to serve the needs of the water supply system. This device allows to avoid constant start-up of the pump engine and to ensure stable pressure and pressure in the system;

- Pump. In this capacity, centrifugal self-priming or vortex aggregates are most often used. The delivery system can be equipped with a remote or internal ejector, which increases the possibility of suction due to the Bernoulli effect, while reducing the overall performance of the system;

- Pressure switch. Here we see an element of the automatic control system, which is configured so that when the pressure rises above a predetermined value, the relay turns off the power supply to the pump motor, and when the pressure drops below a predetermined value, the engine turns on again;

- Check valve This element of the system does not allow liquids to flow in the opposite direction and leave the storage tank or the water injection nozzle, because if air enters the system, the pump can fail;

- Power connection node. It is an ordinary single-phase or three-phase (depending on the design) plug for the corresponding outlet, and also contains fuses and a grounding system.

The accumulator is very simple: inside a steel cylinder there is a rubber bulb, around which there is compressed air. The pear is connected to the inlet, where water is pumped through the check valve, and from where this water enters the water supply system when the faucet or other sanitary device is open.

When pumping water pear increases in volume, compressing the air in the cylinder. Thus, the kinetic energy of the pump engine is stored as the potential energy of a compressed gas that tends to squeeze fluid from a pear. At the entrance to the cylinder set pressure switch, which is embedded in the gap in the power supply circuit of the pump motor.

With the help of special nuts, the relay is adjusted so that when the upper pressure limit is reached, the relay opens the circuit and the engine shuts off. Then, when water is pumped into the water mains during its operation, the pressure in the battery cylinder drops, and when the pressure set by the tuner sets the lower pressure limit, the relay closes the circuit and the engine starts to pump water into the bulb of the battery cylinder again.

Note! The design of the pumping station is based on the principle of self-regulation or automatic control of the system. The values of the pump on and off pressure are determined based on the parameters of the water supply system, the number of water intake points, the well productivity and other parameters.

Species

To find out how to choose a pumping station for a well, we will have to understand the types of stations and understand what their differences are..

There are three main types of systems, depending on the design of the liquid suction system:

- Direct suction system. The pump creates a vacuum in the water intake pipe, and the atmospheric pressure pushes the liquid into this pipe. The problem of the system is that, due to the limited air pressure in the atmosphere of our planet (about 1013, 25 hPa), the column of water that this pressure can push up is just over 10 meters;

- System with integrated ejector. Here there is an indirect suction of water: the pump creates a jet, which, when passing through the nozzle of the ejector, creates a reduced pressure in the suction chamber and under its action draws water from the well. The advantage of this system is that the pump is insured against dry running, because it continuously pumps water in the recirculation circuit;

- Remote ejector system. In this case, the design assumes that the ejector is immersed in the well, and now the height of the column does not concern us, since the apparatus is located near the water mirror. Here, suction is also carried out due to the Bernoulli effect in an indirect way, but the performance and efficiency of the system falls in favor of the possibility of lifting water from a great depth.

The first kind of system can use a pumping station for an Abyssinian well, since its depth does not exceed the capabilities of atmospheric pressure. Also, this system is suitable for shallow sand sources, but if their depth reaches 15 meters (all that is greater than 9), then such a station will not work.

The second type has the same scope as the first one, it is simply protected from pump breakdowns due to air plugs entering the pipeline. This is a more progressive design, but its price is higher.

The system with remote (submersible) ejector allows you to pump water from a depth of about 40 meters. Most often, this option is used at a depth of 20 meters or 25 meters, but the performance of such a pump is limited to low efficiency and therefore does not work well for farms with a large number of water intake points.

There are also constructions where instead of a hydroaccumulator a storage tank is used, in which the pump is turned on and off using a float mechanism. Such a model is considered obsolete, since when the float fails, the water will flood your house, and we will not dwell on it in detail.

For the convenience of calculating the water consumption of the plumbing at home, we have compiled a table with the average consumption values of various plumbing fixtures:

| No. n / n | Water intake point | Average consumption, m3 / h |

| one | Irrigation crane | 1.5 |

| 2 | Whirlpool | 1.4 |

| 3 | Standard bath | 1.1 |

| four | Washing machine | 0.7 |

| five | Shower cubicle | 0.7 |

| 6 | Dish washing machine | 0.7 |

| 7 | Kitchen sink | 0.7 |

| eight | Toilet "tulip" | 0.7 |

| 9 | Urinal | 0.4 |

| ten | Bidet | 0.4 |

If you add up the flow of all your water points, you will get the necessary performance required for the simultaneous operation of all taps.

Note! To determine the type of equipment you need, you should know the level of the water mirror in the well (dynamic level), as well as the required performance of the water supply system. Knowing these parameters, you can easily select the desired unit.

Benefits

As it is known, not only surface stations, but also submersible pumps are used to equip aquifers. What are the advantages of outdoor units to submersible?

There are not many of them, but they are quite significant:

- The most important advantage is the low cost compared to expensive deep-seated devices. If you do not need to provide greater performance or pump water from a great depth, then it does not make much sense to spend money on a submersible device for a well;

- Surface location allows easy and convenient access to equipment for its maintenance and repair in the event of a breakdown or accident. To perform the cleanings or adjustments of the deep well pumps, they have to be removed from the casing, which is quite troublesome and not always easy;

- When the unit fails, it can be easily replaced, since the cost of replacing such pumping equipment for a well will not be much affected by the family budget, and the complexity of the work is available even to the amateur;

- A device with a built-in or remote ejector is not afraid of the ingress of air into the system, since the recirculation circuit fills the pump suction constantly with water;

- Many models of stations can be used as a portable option for watering gardens or other purposes.

Note! As can be seen from the characteristics, it is advisable to use surface water supply systems in the country, in a small farm, in a private household with a low water consumption. For the maintenance of artesian wells or very large farms such stations are not suitable.

disadvantages

Like any other equipment, surface water transfer devices have several disadvantages:

- The depth of the well, which can be serviced by a conventional station without a submersible ejector, is no more than 8 to 9 meters. Why not 10.3? This is due to the loss and non-ideal working conditions of the equipment;

- A surface pump or a centrifugal station produces a rather perceptible noise, and when the equipment is located inside the house, this noise will be heard by its residents;

- When preserving the summer cottage for the winter, the unit located on the surface will have to be hidden or taken away with you, as it can be stolen or damaged;

- The station requires a certain place in the technical, utility or basement room, which is not always possible to allocate;

- When the engine is running, a sufficiently powerful vibration occurs that can harm the surrounding building structures and the pipeline connected to the system.

Note! Despite all the shortcomings and limitations, the usual pumping station with a pressure of 45 meters is enough for the needs of a family of 4 people.

Installation

For those who wish to connect the equipment with their own hands, we have compiled a small instruction:

- In the selected location of the station we make a solid foundation. The most convenient way is to make a podium of brick or concrete 1.2 - 1.4 meters high;

- We place a rubber mat with a thickness of 10 - 20 mm on the podium to dampen the vibration. We install the complex on legs, fasten the legs with anchors to the podium through the mounting holes;

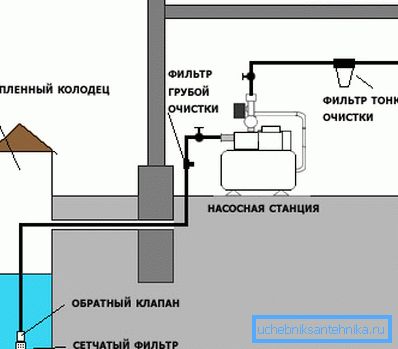

- From the well to the pumping site we dig a trench deep below the level of soil freezing, in which we lay a pipeline of polyethylene or other plastic. We supplement the suction end of the pipe with a check valve and a coarse filter (a regular small stainless steel mesh;

- At the end of the pipe coming from the water source, we wind the inch coupling with an external thread, to which we attach a check valve, then a metal corner fitting, followed by a straight tap “American”. All this is connected to the suction port of the system;

- The outlet of the unit is continued with an “American” crane, to which we fasten a combined rotary (90 degrees) coupling made of polypropylene to the threads. Solder the water pipe to the coupling;

- The vertical suction pipe is connected to the horizontal part of the underground pipeline with swivel fittings or couplings;

- Fill the pump with water through a special hole (read the instructions for the device), open the taps and make a test run of the system;

- If the test is successful, we dig in the trenches, and seal and close the place where the pipes enter the well.

Conclusion

As can be seen from our instructions, installation and connection of the pumping station is not so difficult. To assemble the plumbing, you can call the wizard, and you can do it yourself by following the points in the provided guide. Also help you video in this article.