Well pumping stations: definition, principle of operation,

Many summer cottages and country houses do not have central water supply systems and are forced to equip their own sources in the form of wells or boreholes, since it is the presence of uninterrupted water supply that is one of the main indicators of comfort.

To ensure uninterrupted water supply, a special pumping station is installed at the well or the well, which provides a dwelling house or site with constant water pressure. This makes you independent of the central system, neighbors, or water brought in by tankers.

Such stations are usually collected independently, and they are installed on Abyssinian wells, where the level of the aquifer lies at a depth of 5 to 15 meters.

What is a pumping station

The pumping station for the Abyssinian well is a set of various units and a piping system that serves to raise drinking water from a well, clean it and create a constant and uninterrupted pressure in the home water supply system.

Stations may differ from each other:

- the presence of various units;

- sensor system;

- power.

However, the principle of operation is the same for everyone.

The package of such a system includes:

- self-priming pump to force the movement of fluid;

- hydraulic accumulator with a volume of from 10 to 100 liters, depending on the number of consumers and the required volume of fluid consumed;

- pressure switch in the system;

- pressure gauge;

- pipelines for directing water to consumers;

- coarse and fine filter system.

Such components as the hydraulic accumulator and the electric pump are selected for each system separately, taking into account many indicators. Before choosing a pumping station for a well, it is necessary to carry out a large number of calculations.

It is extremely difficult to determine the parameters of the system on your own, therefore it is recommended to contact specialized companies, where qualified engineers, having extensive experience, will do all the necessary work. The price of such a service is not so high, but you should not neglect it.

Principle of operation

The principle of operation of the station is as simple as possible. The electric pump fills the supply tank with water, thus creating pressure in the water supply system from the well. When you open the valve on any consumer, the pressure in the supply tank begins to decrease.

Reaching the minimum value, the pressure switch is activated and turns on the electric pump. After the pump has refilled the tank and created the required maximum pressure, the relay is activated again and switches off the pump.

Many systems are equipped with automatics that control the load of the pump, its temperature and speed. In the absence of fluid in the system or overheating of the electric motor, the automation disconnects it, preventing it from breaking.

Types of pumps

In most cases, the pumping station in the well is completed with centrifugal self-suction pumps, which can have two variants of the design:

- the ejector is built into the housing of the unit;

- remote ejector;

- units without ejector;

- multistage pumps.

- Units with a built-in ejector (photo) provide high pressure in the system, the output jet can reach 40 meters, however, the working fluid can be lifted from a depth of no more than 8 meters. Such units can operate in the absence of liquid without overheating. At start-up, the pump expels the accumulated air from the system, and then draws in liquid. Such pumps are reliable, but they also have the disadvantage of noise. For this reason, such a pumping station is installed in the well initially to mute the noise.

- Units with a portable ejector (photo) can lift water from a depth of up to 45 meters. Such units when working produce little noise and are usually installed in the house. Remote ejector is lowered into the well and immersed in water. These devices consume a small amount of energy at high performance, but with air in the system, the pump quickly overheats and shuts down. To prevent the outflow of fluid back into the well, a special non-return valve is installed on the suction line.

- Stations without an ejector (photo) are fundamentally different from ejector stations according to the operation scheme. The principle of operation is a multi-level system of wells, each of which has its own pump, pumping water to the next level. The main working tank is installed at a certain height above the ground, thus creating the natural gravitational pressure of water in the water system of the house. Such a system is used to provide water to a large number of consumers in a particular area. Today we can observe them in the form of high water towers with an extended upper part, but in private houses such a system is rarely used because of the difficulty in installation.

- The pumping station for the Abyssinian well with a multistage centrifugal (vortex) pump is used in systems where very high pressure is needed. The units in their design are as simple as possible and work practically without noise. They do not need a non-return valve, since they are already equipped with them initially. Can work at idle and not afraid of air. However, they require a good filtration system, because a small grain of sand can damage the pump if it gets into the pump.

How to choose a pumping station

The choice of a pumping station for a well is the most important event. Today, there are a huge number of different manufacturers on the market, who with their assortment can satisfy the needs of any client.

Tip: Before making a decision on the acquisition of such a station for your home, you must first examine the characteristics of the source itself. Each well or well is supplied with instructions for use with technical specifications.

From this manual you can find out:

- well depth;

- casing diameter;

- static and dynamic water level at the source;

- well flow rate;

- performance.

After reviewing all this data, you will be able to understand which pump station to choose for the well so that it works efficiently and without overloads.

Next, you need to derive the average amount of water consumed, taking into account such indicators as:

- the number of residents in the house;

- availability of irrigation or irrigation systems;

- household appliances consumed water (boiler, dishwasher, washing machine).

It is worth noting that such calculations are extremely difficult to do without special theoretical knowledge, which is why the pumping station for the well needs to be calculated by professionals using special computer programs.

Where to install a pumping station

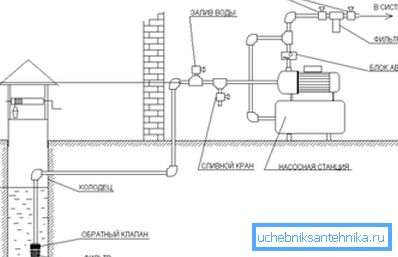

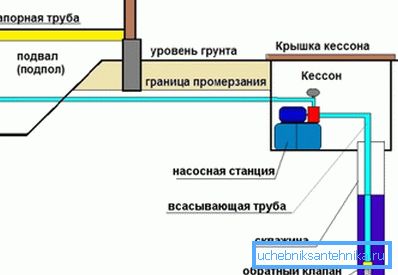

The station can be installed in three places:

- caisson well;

- basement of a dwelling house;

- separate structure.

In terms of practicality and ease of maintenance, it is better to choose a unit in the basement of the house. In this case, the basement must be insulated from moisture and have heating, since the system has electrical components that can fail and cause a short circuit, and can also freeze if the temperature in the basement drops below zero in winter.

The unit must be installed on a wooden or plastic stand without touching the walls of the building, because during operation, the electric pump creates vibrations.

If you install a pumping station for a well with your own hands in the caisson due to the noise of the electric motor, then the caisson itself must be additionally warmed, and the station must be installed below the ground freezing level. Usually in temperate areas, the level of freezing does not exceed 2.5 meters.

Tip: if the depth of the mine is more than 12 meters, then it is better to use a two-pipe station with an ejector. With a well depth of less than 12 meters, a single pipe system is sufficient.

If the system creates a lot of noise, but you do not want to lower it into the caisson due to the inconvenience of maintenance, then you can build a small extension next to a well or house, in which the station will be located. However, this structure must be insulated, waterproofed and ventilation provided for the room.

Station installation and connection procedure

Let us consider in detail the connection of the station with an ejector to the water supply system of a residential building.

- the first thing going to the ejector (cast iron device with three outputs);

- a mesh filter is mounted in the suction side of the ejector to prevent large particles from entering the system;

- Adapter couplings are attached to the ejector outlets to be connected to plastic pipes (if they are not built into the ejector itself);

- Plastic pipes are laid in trenches for the pipeline (trenches are dug to a depth below the soil freezing and provide additional insulation);

- the ejector is installed at the desired depth and the hole of the pipe outlet from the well is sealed tightly;

- usually a coarse water filter is installed before entering the pump, which purifies water from small particles of sand;

- at the outlet of the pump put a fine filter that purifies water from dissolved heavy elements in the form of iron and salts;

- the electrical network to power the unit must be equipped with its own automatic machine.

Note! It is necessary to adjust the pressure switch correctly and make sure it works first time it is started. Usually the manufacturer attached instructions for fine tuning.

Since such systems work with electric motors and have a large amount of electronics to ensure proper operation, it is extremely important to protect equipment from power surges in the power grid. Regular surge protectors are not suitable for this.

Conclusion

It is strongly recommended to get an uninterruptible power supply. You can install a special protection system in the electrical system of the whole house, but such equipment is quite expensive.

It is extremely important to monitor the condition of all filters that are integrated into the system and to prevent them from becoming clogged. The dirtier the filter, the harder it is for the pump to pump water and it has to work at elevated loads. And this leads to overheating, increased wear of rubbing parts and shortened service life.

Also be sure to watch the video in this article in order to replenish the knowledge base with useful information.