Well-quencher and its purpose

Today, sewage wells, as well as the pipeline system as a whole, are indispensable elements in country houses and private houses. After all, a stay in a country house should be as comfortable and pleasant as possible, in addition, you need to think about safety and sewage disposal.

One of the important elements of such a sewage system is a sewer cesspool, to which this article is dedicated.

What is a sewer absorber

Wells dampers have received such a name, as they are used primarily to quench the pressure of sewage in those areas where drains are gaining an unacceptable speed. As a rule, they are installed after the KNS before the sewage is supplied to the treatment plant, which ensures that the latter work in a pressure-free mode.

Immediately it should be said that the dampers belong to the drop wells. Therefore, they are often used not only to change the flow rate, but also to combine pipelines of various depths into one network.

In addition, the drop wells allow you to connect the sewer pipes at a level higher than the tray part. And according to SNiP 2.04.03-85, these structures are also necessary for flooded releases in the last well in front of the pond.

The size of the structure depends on the diameter of the pressure pipeline, which is connected to it.

Tip! If the pipeline has a diameter of up to 600 mm and the drop height is up to 0.3 m, then it is allowed to perform a drop without installing a differential well. In this case, a smooth discharge in the manhole is performed.

From the foregoing it follows that not all sewage systems are needed by dumpers, however, in some cases it is impossible to do without them. In addition, in domestic use, dampers can also combine the functions of turning and viewing structures of wells.

Types of drop wells

Materials for the well

Wells dampers can vary in a number of ways, and first of all they differ in the material from which they are made.

Most often they are made:

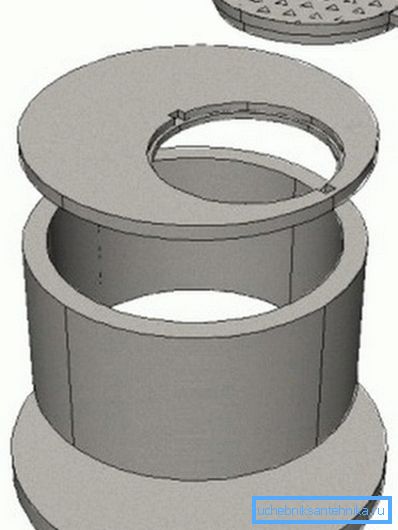

- Concrete - such structures are highly durable, so that they can be used without any restrictions on any types of soil. The only drawback of concrete is that it quickly collapses under the influence of water and various chemical elements.

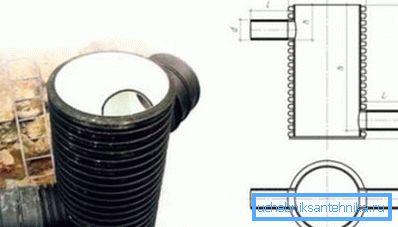

- Plastic - has a number of positive qualities, such as exceptional durability, tightness, low price of the product, ease of installation, etc. The only drawback is the lack of strength and low weight. Therefore, in areas with heaving or mobile soil, the pit for the well is pre-cast with concrete. (See also the article Plastic sewer wells: installation features.)

Purpose of absorbers

In addition, dampers can be:

- Industrial - such structures are often used in the organization of urban storm sewers.

- Household –– they are used much less often, as a rule, only in areas with autonomous systems of sewage treatment plants.

Device types

As we found out, the quenching of wastewater flows is only one of the few functions of these wells. In accordance with this, their device may also be different.

In particular, they are:

- With a waterspout in the downstream and practical profile.

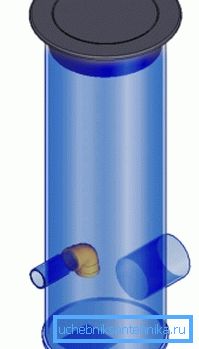

- Tubular - there are different designs, but they are all united by the fact that they are made on the basis of a vertical pipe.

- Equipped with a special water-drain wall.

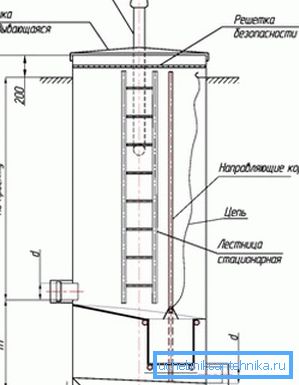

- Multistage wells of mine type, which quench the flow rate as it follows the cascade.

- Equipped with a trash can to protect wastewater treatment plants from clogging.

Separately, it should be said about the well-fast currents, which perform the opposite function of the dampers, i.e. accelerate the flow in those areas where it is possible to slow down.

Tip! You can install the quick-run system with your own hands in the autonomous sewage system, if there is a doubt that the flow volumes will be enough for self-cleaning of the pipeline.

Well construction

It is quite possible to execute a damper on the dacha area of concrete, like any other type of well, independently.

Instructions for its implementation is as follows:

- The first step is to dig a pit of the appropriate diameter and a depth of at least one meter.

- Then a concrete pad is poured in, the height of which should be at least 150 mm. At the same time, it should protrude 150–200 mm beyond the walls of the well. In addition, when pouring the bottom of the structure, it is necessary to take into account that it should be located below the mark of pipes by 20-50 mm.

- After the concrete cushion hardens, you can proceed to the installation of concrete rings. They can be bought ready-made, or you can also do it yourself, though you need to make formwork for this. When self-manufacturing, the diameter of the rings must be at least a meter.

- Further, in the walls of the structure, holes are made for pipes of the required diameter at a different level. The difference is usually 20-50 mm.

- The final stage is the introduction of sewer pipes, which should protrude beyond the walls of the well by 50-60 mm.

At this, the device of the sewage well is completed, however, for ease of maintenance, running brackets can be mounted into the walls.

Conclusion

Wells dampers can solve a number of problems associated with the organization of autonomous sewage. In some cases, without slowing down the flow, the system simply cannot function normally.

However, if you are not a specialist in this field, then it is better to entrust the design of sewers to specialists who will determine which well and where to install it. Additional information on this topic can be obtained from the video in this article.