Well rings of concrete goods - making yourself

As a source of water for the organization of the water supply system is most often used well. The basis of any well are rings, to which, during the construction phase, increased requirements for moisture resistance and strength are imposed. These products are now used in various structures of water supply systems. In connection with the peculiarities of modern construction, concrete goods are used for wells as well as sewers.

It is important that the structures are necessarily made of reinforced concrete, because when they are used for a septic tank, the material can be deformed under the influence of negative phenomena. As a rule, these products are manufactured in the conditions of production at the enterprises that received the appropriate license. However, making the rings yourself is not difficult. To do this, it is not necessary to have special skills.

Well rings function

We will understand what these products can be used for. First of all, they are used for wells.

They are also used for:

- arrangement of highways for collecting precipitation;

- equipment of bridges through trenches, wells and other treatment facilities;

- they can be used in construction as a non-separable formwork when installing the foundation.

Modern manufacturers offer rings made from various materials. Due to its lightness, plastic has become very popular.

According to its strength characteristics, it is practically not inferior to reinforced concrete, and its price is much lower. However, it cannot provide some properties, for example, plastic has a low frost resistance.

Why do concrete goods rings for wells received such a distribution?

They have such advantages:

- long service life;

- resistance to high loads;

- moisture resistance;

- environmental friendliness, which is important when using well water for domestic needs;

- ease of installation;

- acceptable price.

Note! The quality of the finished products must meet many requirements. This is sufficient density, the ability to withstand high loads.

In addition, RC rings for a well should be consistent with environmental standards. As the water passing through the structure will be used for drinking.

Sizes of reinforced concrete rings

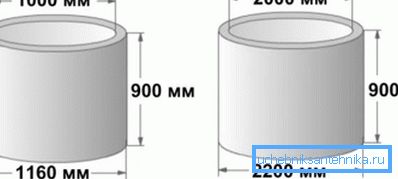

The volume of a ring made for plants at a b for wells can be various. As a rule, their height is 0.9 m, and diameters can be from 1 to 2 m. In self-manufacturing products, requirements may not be so rigid (read also the article Rings for a well with a lock: characteristics and advantages).

In this case, the dimensions of the well rings of reinforced concrete can be. For example, the internal diameter can be made in the range from 0.8 to 1.2 meters, the height can reach 1.2 m, and the wall thickness - 6-8 cm.

Manufacturers offer finished products equipped with grooves to facilitate the connection. They can be performed without the use of reinforcement, because the life of the rings is reduced.

However, it is easier to make your own models with even ends. At the same time, the mass of rings with a diameter of 1 m, in the construction of which reinforcement is provided, reaches 800 kg, the mass of such products without reinforcement is 500 kg.

Independent production

Formwork making

To obtain a product it is necessary to pour concrete into the prepared form - formwork. The form will be folding, consisting of two rings made of metal. Metal drums, air ducts or pipes of the required diameter are well suited for these purposes.

Of course, the use of wood will be problematic, although its use is not excluded. In the presence of two cylinders of the required sizes, proceed to the formwork.

The following instruction will describe the sequence of work:

- Outside the cylinder having a larger diameter, draw vertical lines dividing it into equal parts.

- On the inner side, the same lines are performed, along which the walls are cut by a grinder.

- As a result, we received a collapsible form that allows you to get a ring of concrete wells.

- The corners with bolt holes must be welded to the outer side of the form with along the cut. In this way, the connection of the forms during the pouring will be ensured.

- Repeat the operation with a small cylinder. The corner is welded from the inside.

The result should be a design similar to that shown in the photo.

Technology of pouring mortar into the mold

After preparing the concrete mix, and carefully stirring, it is placed in the form. After that, using the metal rod, the mixture is compacted. This must be done to ensure sufficient strength of the product.

Note! When filling the form with your own hands, you should try to make the end surface as smooth as possible, since it will be the connecting surface of the concrete goods of the ring of wells.

In the process of pouring, you can apply the vibration, which will allow you to fill all the voids and compact the mixture to the maximum. After this procedure, you can add some more solution.

The use of special covers is necessary to ensure tightness and to prevent foreign objects from entering the solution. It is especially important to protect the forms with a lid if they are outdoors.

As a rule, on the third or fourth day the form is taken apart. But at the optimum temperature and humidity of the concrete products, the well ring can be ready the very next day. After removing the product can not be rolled and moved somewhere, because it has not yet gained sufficient strength.

Tip! To improve the performance of concrete, it is recommended to wet it with water for a week. After ten days the ring will be ready for use.

Conclusion

Installation of reinforced concrete rings for the well is carried out with the help of cranes, performing a semblance of a column. To ensure the strength of the connection of concrete goods, rings for the well are fastened together with brackets. One connection will need at least three plates.

When choosing b, rings for wells, many prefer plastic structures due to their lightness. However, reinforced concrete is still popular because it has a long service life and environmental friendliness. You can also do it yourself, as you can see.

For more information, see the video in this article.