Well workover: what is it

Like any equipment, sooner or later, during its operation, wells require repair. At the same time, it can be planned, i.e. current and capital - designed to troubleshoot serious problems.

At the same time, underground repair of wells is usually carried out - and the overhaul of wells is no exception.

Planned repair operations

First, we will deal with the fact that such maintenance work.

Process features

Maintenance is the following.

- Restoration of efficient operation of wellhead and downhole equipment.

- Work on changing the type of exploitation mode.

- Cleaning equipment items, the bottom walls and the well itself from a variety of sediments (hydrate plugs, paraffin, sand, silt, corrosion products, etc.).

A complete list of repair works that relate to planned activities is presented in the "Rules for the repair of wells", 01/11/97..

The instruction divides the current repair operations into the following types: preventive and remedial.

- The first type is scheduled maintenance. Its purpose is to prevent a decrease in the efficiency of well service caused by the current problems of their operation. Preventive repairs are planned in advance and are carried out on schedule.

- The recovery type of the current repair is due to a sudden complete or partial shutdown of the well, due to the failure of its equipment.

Planned repair operations may include these types of work.

- Cleansing wells with their own hands from sand plugs using a chopper or flushing.

- Replacing the pump.

- The elimination of the breaking of the rods or their lapel.

- Replacing rods and tubes.

- Change the parameters of immersion tubing.

- Replacing or purifying the sand anchor, etc.

Another kind of events

In addition to the concept of "capital-current well repair," there is the term "well-operation." Such measures are designed to increase the impact of developed reservoirs of water, oil and gas. They are also specialists in repair work.

Note! A well-operation is a set of actions for the introduction into the reservoir of reagents that initiate chemical, physical and biochemical reactions that are aimed at increasing the displacement rate of the resource extracted.

Capital types of repair work on wells

Now that includes the purpose and types of workover.

Varieties of operations

Such operations are activities that involve:

- with restoration of work of upsetting pipes and columns;

- replacement or complete repair of cement rings;

- restoration of the bottomhole zone;

- elimination of the consequences of serious accidents;

- lifting or lowering various equipment with separate type of operation or injection.

Specifically, such work may include the following operations.

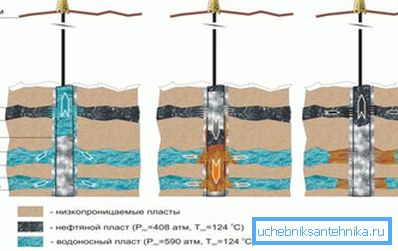

- Insulation measures, for example, isolation of flushing fluids or produced water (waste, fresh).

- Shutdown well.

- Transfer of equipment to another object.

- Repair activities: building of a concrete stone, construction of a second trunk, ribbing or restoration of the hermetic condition of casing strings.

- Special types of impact on the bottomhole formation zone. These methods can be chemical, physical or physico-chemical.

- Overhaul and underground repair of wells often consists of fishing operations.

- A separate place is occupied by the elimination of wells, due to any reasons.

Recovery work

Most often, such events consist of fishing works. The need for them arises when the underground equipment, cables, rods, tubing, etc., is turned away or cut off. Breaking and hitting the face, the equipment elements are crushed and the casing and columns are wedged.

This often leads to a well failure.

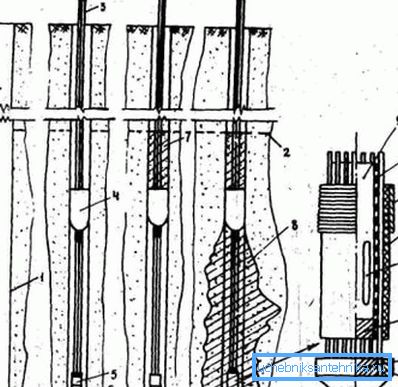

- To correct the consequences of such an accident, you must first shut down the well.

- Then a “seal” descends into it, intended to study the separation area.

- On its aluminum or lead disk, which is pressed against the break point, traces of a torn element appear. They help to know the characteristics of the separation and its location in the casing. After that, experts can choose the right fixture. This may be a "spider", overshot, trubolovok, diversion hook, fishing bell.

- Capture by the device of the torn-off part, not in all cases ends with its complete extraction and cleaning of the well. Based on this, it is necessary to use hydraulic jacks. They help in parts to get torn pieces of equipment.

- When such an attempt to cleanse the wellbore ends with a detachment of a deflated device (for example, a drill pipe), as a rule, a new trunk is made. It starts to operate separately, the old well is drowned out.

The operations of isolating casing and columns, in which defects arise due to collapse or corrosion, are also complex. A significant price and the cuff or retrieve pipes that are stuck with cement. They need to be drilled with specialized bits of the coronal type or pipe cutters.

With a strong watering of the wellbore, there is a need for isolation of the interlayer or the section through which the water broke. Such an invasion occurs along the gap behind the pipes, as a result of the partial destruction of the cement stone.

Preparation for repair

- Initially, you must carefully examine the well using geophysical methods to detect the causes of problems.

- Only after processing the obtained data should be planned and carried out specific measures for repair work.

- There are many technological methods that can be used to repair a well. The specific method is selected based on considerations of expediency.

Note! Overhaul and current repair of wells should be regulated by project documents and guidance cards. They indicate the sequence of activities, the equipment used and the technical means.

- The effectiveness of the repair should be determined by comparing the results of the inspection of the object before and after the work, as well as comparing its water content, productivity level, etc.

- As well wear and tear, the need for its repair will grow. To solve such a problem in traditional ways, sometimes it becomes difficult. Based on this, at the moment, new techniques have been developed that reduce the labor and financial costs of repairing wells.

The latest repair technology

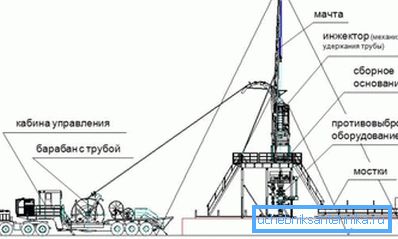

The classic way to restore the performance of objects is the use of compressor tubing. However, now developed and is using new equipment for workover of wells.

With it, the following methods of work are carried out.

- Rope way.

- Cable cable method.

- Technology using flexible pipe types.

- Hose-rope method.

- Hose-cable technique.

- This method is based on the use of ropes for delivery to the well bottom or to the insulated area of special containers-zhelonok.

- They can deliver tampon materials, chemical reagents, explosive compositions and elements for torpedoing, installation of “packers”, fire-fighting projectiles, to the site of repair.

- Ropes are also used for the descent of the mechanical type of scone. To make such a device work, you need its support on the bottom of the well.

- This technology does not replace all types of work required when the well workover is carried out. On this basis, its use only partially facilitates and makes repair work less expensive.

Cable machinery

Cable rope

- This technology uses ropes with electrical wires mounted in them.

- They serve for the message to the repair container of electrical impulses. Thus, you can manage his work.

- For example: open the valve or undermine the explosive compositions that distribute plugging material. Cable cables can deliver containers that weigh up to 0.2 tons to the wellbore.

Note! Cable, as well as cable-cable measures should be carried out in a completely plugged well. The works are carried out with the help of a winch, which is installed on a special truck - an analogue of a mobile geophysical cardboard station.

Application of flexible tubes

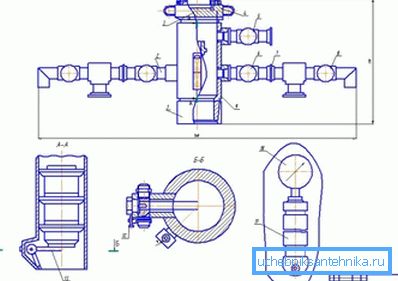

- This method of repairing consists in the fact that flexible pipes are unwound from a drum having a cross-section of several meters. They are delivered to the wellbore through a special rectifier device, which is installed in the mouth. Tubes with a cross section of up to 25 millimeters are made of a special flexible type of steel. They coil on the drum, which is located on the trailer.

- On the mouth of the object is mounted a special mechanism. He forcibly pushes pipes into the wellbore, simultaneously straightening them. The rate of descent / lifting tubes is 50 cm / s. This circumstance greatly facilitates launching / lifting measures, which are replaced by continuous feeding or lifting of the tubular column.

- Tubes delivered to the wellbore body are used to inject acidic compounds, air, various working gases, flush the wellbore from clay dissolved in water, pierce plugs from sand, etc. They can serve as a drive for small turbo drills.

- Flexible tubes can be delivered through a compressor-pump tubes in these types of wells: gas-lift, flowing and injection, without raising them. This circumstance is important especially when the lowered tubing shoe is equipped with a packer.

Hose ropes and cables

- Repair of wells, using hoses, is similar to the previous method. However, flexible steel pipes in this case replaces the hose having a metal braid. It informs the fixture of the desired level of tensile strength, due to the effect of gravity, as well as external and external pressure.

- Hose ropes with a cross section of up to 6 cm are now being produced. They can withstand breaking loads up to 300/350 kN and are capable of operating at an internal pressure of up to 15/20 MPa.

- Hose ropes are wound on the winch drums of the desired capacity. The inner ends of the fixtures have an outer lead. Through it, you can pump fluid and with the rotation of the drum.

- Hose ropes are fed to the mouth, and then pushed into the trunk of an object by a traction device of a chain type - “roller conveyor”.

- At the working end of the repair device, you can install a hydraulic-type downhole motor (turbo-drill) for piercing plugs from sand, drilling cement glasses, etc.

- The necessary repair fluid is transported through the hose, based on the type of repair work being carried out. This may be an acidic composition, surfactant or cement mixture.

- From one to three insulated electrically conductive cables can be embedded in the metal sheath of the rope to transmit impulses to downhole devices or to transmit warning signals from them to the surface.

- In this case, the hose rope is converted into a hose cable. It significantly increases the possibility of using such a device during repair operations.

Note! The use of hose-cables makes it possible to avoid the stage of unscrewing and screwing the pipes. Due to this, the time spent on launching and lifting activities is reduced several times. This saves workers from heavy labor costs and makes repairs safer.

Conclusion

Overhaul of wells is a responsible and serious complex of works. The optimal solution is to entrust them to specialists who will carry out the operations correctly and competently. Check out the video in this article. It will give you the opportunity to gain additional knowledge on the topic.