Wellhead for the well itself

The wellhead is one of its important structural elements, the main function of which is to seal the source, protecting it from the entry of groundwater, foreign objects and other pollutants. It also serves for mounting pumping equipment, water pipe and electrical cable. The water level in the well is measured through the heading device. On sale there are factory-made ogolov of polyethylene, metal, but it is not always possible to buy them, in this case it is easier to make it yourself.

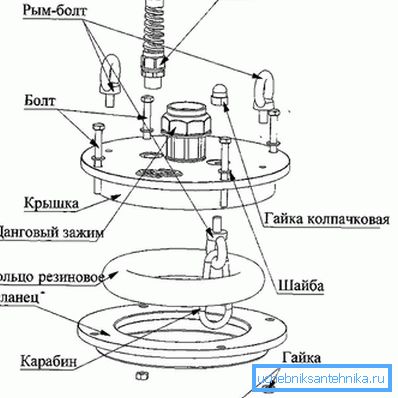

Design

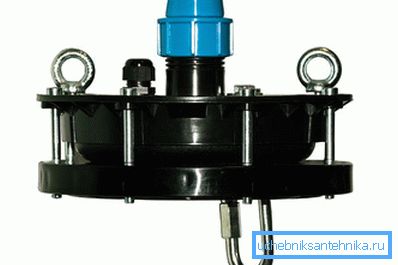

The typical design of the tip consists of the mouth of the nozzle and the base plate, which are interconnected with bolts and nuts. The wellhead is concreted into the foundation of the wellhead. The size of the tip depends on the diameter of the well and the mass of the pumping and lifting equipment. The more these parameters, the more powerful should be the tip. It is firmly concreted, as it will receive and smooth the vibration from the pump.

If the well is equipped with a conductor, then the base plate can be attached directly to it through an intermediate flange, to seal the butt joint using a rubber or paronit gasket in the form of a ring.

As a rule, caps are made of metal or cast iron, but for small wells you can use factory plastic. They have a more attractive price, but it makes sense to use them only when the well is up to 30 m deep and the weight of the pump with water-lifting pipes does not exceed 200 kg.

Manufacturing

The cap on the pipe is installed without any difficulties, but before you make it, you need to take care of the presence of some consumables. You will need:

- nozzle (pipe section) with a diameter of several centimeters more than the casing;

- sgon of the same diameter as the pipe from the pump;

- 1/2 pipe for cable laying;

- sheet steel, 8–10 mm thick for the manufacture of the cover and flange;

- thick rubber or paronite for the manufacture of gaskets, 3–10 mm thick;

- eye bolt (this is a bolt with a rigidly connected metal ring) in an amount of 3 pcs., for dismantling the top cap and for fastening the cable that holds the pump;

- four long bolts with nuts.

First, a cover and a flange of a round or square shape is cut from a metal sheet. In the piece that will perform the function of the flange, we make a hole for the diameter of the wellhead. In the piece for the cover, drill a hole under the nozzle for connecting the lifting pipe and under the sleeve for the cable. Drill holes in the plate for mounting bolts and eye bolts. Flange welded to the wellhead pipe. In the top cap, we weld the sgon to attach the water-lifting pipe and the cable connection, fasten or weld eye-bolts: two on the upper side of the cover, one on the bottom.

Mounting head

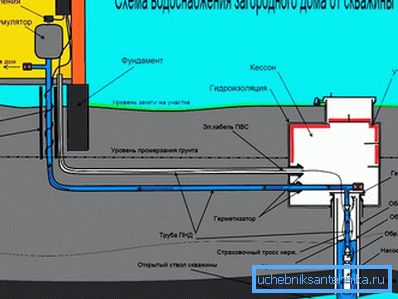

When installing the tip, a mistake is often made, which lies in the fact that it is mounted on the casing pipe, and this is extremely undesirable. If you mount the tip on the casing, it can lead to the following troubles:

- vibration, which is transmitted from the pump to the casing, destroys the annular carburization, which, in turn, increases the risk of contamination into the well;

- destruction of the annular space leads to a decrease in the life of the well.

Installing the tip on the casing can be justified only if the well:

- used periodically;

- It has a shallow depth and a low mass pump is used.

The cap should be mounted below the freezing of the soil, it is better to do in the well of concrete products or bricks. Before installation, a concrete base is made for the wellhead, where it is monolithic. The casing pipe should protrude 20 cm above the top of the concrete base.

The mass of the concrete base should be 1.5 times the mass of the pump with water-lifting pipes and water.

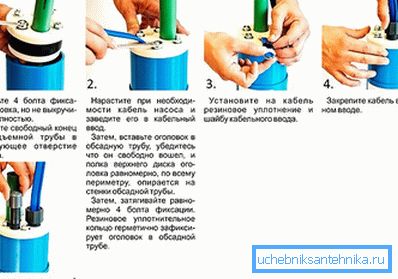

Installation of the pump and water-lifting pipes can be made in 3 days (concrete setting time). The installation procedure of the tip:

- Initially, you need to attach a pipe, cable and cable of the required length to the pump, pull it all together with hose clamps.

- Attach the free end of the cable to the carabiner, which is attached to the lower eyebolt. Pull the cable and lifting pipe through the cap.

- Before starting to lower the pump into the well, place a sealing ring on the flange. After we lower the pump, it is necessary to fasten a cover to a flange.

For the tightness of the tip on the cable, you need to put on a heat shrinkable sleeve, which then sits with the help of a building hair dryer on the nozzle 1.2 ".

To extend the life of the tip it must be primed and painted.

You may be interested to know:

- How to clean a well?

- How to get rid of iron in water from a well?

- How to install a downhole adapter?

Video

The video provides instructions for making a homemade tip for the well: