Wellhead: functionality and options

What is the tip or, as it is also called, the tip of the well? What is this simple device for? What materials is it made from and how is it mounted?

Let's figure it out.

What it is

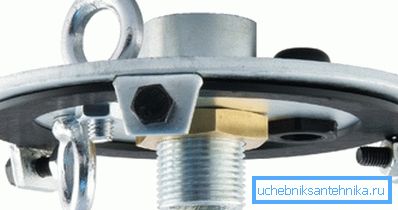

The wellhead is called an uncomplicated device - a prefabricated flange that seals the mouth of the casing. Tightness in modern designs is provided by a rubber ring gasket that compresses the casing when tightening the cap head with bolts.

By the way: it is not difficult to find handicrafts made from black steel made by handicraft or half-homemade on sale. They are welded to a steel pipe.

The product has several additional elements:

- Eye bolt or welded ring for fastening the cable on which the pump is suspended. Optionally it is supplied with a carbine.

- Hole for power cable with seal.

- Fittings for connecting the pressure pipe from the bottom and top. However, it is increasingly possible to see a slightly different device of the wellhead: the nozzles are replaced with a collet - a threaded nozzle and a cap nut with an annular conical gasket, which allow compressing a polyethylene pressure pipe with a diameter of 25, 32 or 40 millimeters.

- A pair of lugs or eyebolts on the wellhead cap. Thanks to them, depressurizing the connection of the cap with the casing, you can lift the entire structure together with the pump.

Why do you need it

The cap performs several functions at once.

- It takes over the load from the cable with a pump suspended on it, evenly distributing it over the end of the casing.

- It protects the well from debris, dirt, foreign objects that may jam the pump when lifting or just affect the water quality.

- It significantly reduces the likelihood of equipment theft. Welded or assembled with bolts with a secret (non-standard-shaped turn-key), cap, to remove, politely, is not easy.

- The end cap does not allow surface waters to get into the wellhead.

It should be clarified: the mouth is usually buried in a pit located below the level of soil freezing. It is clear that in heavy rains the pit can heat up. If you get to the aquifer on the outside of the casing dirty water from the surface will not give a clay lock and / or cementing the trunk, the pipe itself needs to be sealed.

- Finally, the presence of a tip can seriously increase well production. Due to what? Imagine a sealed vessel, partially filled with water. And now forcibly remove from it part of the water through a thin tube. A vacuum is created inside, isn't it? It seems that the analogy is clear: the reduced pressure inside the well acts as a vacuum pump, pumping out increased volumes of clean water from the aquifers.

What they are

The size

The most common, of course, tip for a casing diameter of 125 millimeters. Cause? It's simple: the majority of commercially available household borehole pumps have a diameter of 4 inches, or just over 100 mm.

Since for normal lifting and lowering of the pump, a gap between it and the casing at least 1-2 centimeters is needed, and the price of a running meter of well drilling increases with increasing diameter, the choice of section becomes quite obvious.

More rarely, there are products for sizes 133, 140 and 159 mm. In addition, there are universal designs that can be installed on pipes of different diameters.

Material

What can these devices be made of?

Steel

Ogolovki of her often made their own hands, using a welding machine and grinders. Despite the low cost of manufacturing, this is not the best option - dismantling the welded tip is quite difficult, and you should not forget about steel corrosion.

Of course, steel products are protected by paint and varnish coatings. However, in conditions of high humidity, not every paint can last more than two or three years; any damage to the protective layer opens the way to rust. In addition, damage to the internal coating is unavoidable during welding.

Polypropylene

The price of products from it starts from about 600 rubles. Polypropylene is a lightweight, durable and tough plastic, resistant to corrosion, moisture and chemically aggressive substances. The disadvantages include perhaps limited strength: the maximum load for tips made from this material is limited to 200 kgf.

Cast iron

The cost of cast iron caps is somewhat higher compared to plastic. Higher and durability: the typical maximum load is already 500 kgf. But the service life is somewhat reduced: cast iron is not as susceptible to corrosion as black steel, but it is still not completely protected from it.

Installation

The installation instructions for the wellhead with a sealing gasket are quite simple.

- The casing pipe is cut strictly at right angles to the axis. The cut is cleared of burrs.

Please note: for universal tips it may be necessary to polish the end face. These products do not compress the pipe outside, but are pressed against its end by a flat rubber gasket.

- The cable of the pump is securely fastened to the eyebolt. The pressure pipe is attached to the pump and passed through the nozzle in the tip; The same operation is done with the power cable.

- The flange and cover are consistently worn on the edge of the casing and tightened with each other, compressing the gasket.

- Excess cable and standpipe are drawn out and crimped with cable gland and collet.

Conclusion

As always, the video in this article will offer the reader additional materials on the topic we are discussing. Successes!