Wells and septic tanks: safe water intake and effective

What is the minimum distance between the septic tank and the well for drinking water? Are there any recommendations on their location on the site? How to ensure effective drainage of treated wastewater from a septic tank?

In the article we will look for answers to these and some other questions.

Definitions

First, let's understand the terminology to avoid any confusion.

- Water well receives water from the upper aquifer. Groundwater is treated only by soil filtration: as a rule, it is not about the flow of artesian water into it from the lower horizons.

Anticipating objections: exceptions, of course, exist. But artesian wells traditionally rummaged where there is simply no upper aquifer - in deserts and semi-deserts. At present, they are practically crowded out by wells, which are much cheaper in development.

- A septic tank is a construction of at least one settling tank and a filtering well or filtration field.. In this case, the sump should be reliably waterproofed: untreated sewage should not be in contact with the ground. Thus, with a properly made septic tank, the threat of contamination of groundwater carries only that part of the structure, where settled wastewater is absorbed by the soil.

- The cesspool (also known as the cumulative septic tank) is completely waterproofed and does not pollute the soil in principle.. In theory. In practice, the complete absence of leaks is typical only for plastic containers: concrete and brick structures sooner or later lose their full integrity.

The so-called septic tank (a structure with concrete or brick walls and a drainage bottom) is a source of permanently severe pollution of groundwater.

So, the distance between the well and the septic tank is important from the practical side in the following cases:

- Concrete or brick clarifier (sludges).

- Accumulative septic tank made of the same materials.

When using hermetic plastic containers, only the distance to the filter well or the filtration field, which can be moved a considerable distance from the septic tank itself, is important.

For clean water

Let's put together all the requirements associated with local facilities and environmental safety.

- According to the sanitary rules and norms of SanPiN 1.4.1110-02 (paragraph 2.2.1.1), the minimum distance from a protected water intake to residential and industrial buildings is 30 meters, from a weakly protected water intake - 50 meters. The well definitely falls into the second category. Residential and industrial facilities as a source of possible pollution are mentioned precisely because of the presence of a sewage network under them, which does not always keep its integrity.

- SNiP 2.04.03-85 Sewerage. External networks and facilities take a protective zone for wastewater treatment plants for low-rise construction, equal to:

- For fields of underground filtration with a capacity of up to 15 cubic meters per day - 15 meters.

- For sand and gravel filters and filter trenches with a capacity of up to 1 m3 per day - 8 meters, up to 2 m3 - 10 meters, up to 4 m3 - 15 meters, up to 8 m3 - 20 meters, up to 15 m3 - 25.

- The distance between the septic tank and water supply pipes should be 10 meters or more. The instruction is related to the danger of contamination of drinking water during depressurization of the water supply system.

From the author: to be honest, this requirement looks rather strange. Excessive pressure in the pipeline during depressurization in no way will allow wastewater to get inside. It may be a question of the likelihood of contamination during repairs.

And what practical conclusions can be drawn from such different indications?

Referring to the recommendations that are adhered to when designing cleaning systems professionals.

- On dense soils, the distance from the well to the septic tank should be at least 30 meters.

- On sand and sandy loam it increases to 50 meters, since these soils have much greater permeability to water.

- In the presence of a slope the well is always located above the septic tank on a slope.

Drainage for drains

What should be the drainage well for a septic tank? Consider the general methods of calculating its size and some aspects of construction.

Calculations

If a volume is important for a septic tank, it allows drains to settle for at least three days, then the main parameter for the drainage well or filtration field is the area of the absorbent surface.

It is clear that water absorption by a square meter of soil strongly depends on its composition.

- The sand can absorb up to 80-90 liters of treated effluent per day.

- Sandy loam - about 40-50 liters.

- On loamy soils, it is worth laying 15-25 liters per day in the project.

- Finally, on clay, the absorption may be 10 or less liters.

Tip: for low absorption, the filter well should prefer a filtration field or a trench.

For a well with solid walls, the absorption area is limited by its bottom. Accordingly, in the case of the construction of reinforced concrete rings with a diameter of 1.6 meters, it will be equal to 3.14 x (0.8) ^ 2 = 2 m3. The sandy bottom of such an area can absorb no more than 100 liters per day, which is clearly not enough even for a two-person family.

However, the reader has probably more than once seen a well-functioning well for a septic tank of the size we mentioned. What's the secret?

A simple solution will help increase the absorption area:

- The walls of the well are leaking.

- Backfilling is done not by the ground, but by gravel or gravel.

In this case, with a full well with a distance of 3 meters from the bottom of the water mirror, the absorbing surface will be at least 3.14 x (0.8) ^ 2 + 3 x 3.14 x 1.6 = 17 square meters and will provide absorption at least 850 liters of treated effluent per day.

Materials

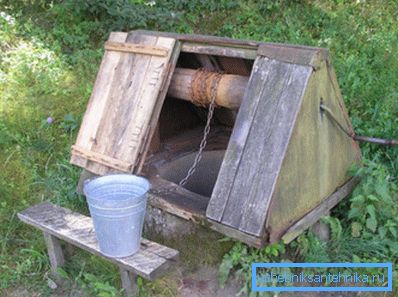

What and how are walls of filter wells constructed?

One of the popular solutions we have already named - reinforced concrete rings.

How is wall perforation ensured?

- Laying between the rings of several full-bodied red bricks.

- The two-hour work of the punch with a crown with a diameter of 65 millimeters.

- Finally, many concrete products plants offer ready-made perforated well rings designed specifically for filtering wastewater into the ground.

No less popular solution is to fill monolithic reinforced concrete walls on the spot with your own hands. The price of cement and sand required for this job will be noticeably less than the cost of the finished rings.

How is this work done?

- The bottom of the pit for 20 centimeters is filled with rubble.

- Along the perimeter of the thickness of the future walls a concrete pad is formed.

- Then formwork is assembled. The use of a pit in this quality is undesirable: a gap for drainage is needed between them and the well. With a lack of material for formwork, it is going to a height of no more than half a meter and moves up as the walls are poured.

- Formed armokarkas. Here, it is not necessary to use traditional corrugated reinforcement: a grid of 5 mm wire and trimming pipes or a corner will also work. The frame elements are knitted with annealed wire.

- Pipes of plastic pipes are laid in the formwork to ensure perforation of the finished wall, after which it is poured with M200 concrete (1 part of cement, 3 parts of sand and 3 parts of rubble).

- After the walls gain strength, the space between them and the pit is filled with rubble.

Finally, a brick filter well is placed on a concrete cushion with brickwork in a half-brick. In each row between the elements of the masonry there are gaps, overlapping the next row.

Conclusion

As usual, the video in this article will offer the reader additional information on the topics touched upon by us. Successes!