What are used wells for sewage

When building a sewage system of any type, it is difficult without special structures to observe their work - wells. The underestimation of the role of these structures can cause the failure of planned or sudden maintenance and repair work. Below we will talk about the types of sewage wells, their sizes and materials used for their creation.

Structure and construction

A typical construction of such structures consists of:

- bottoms;

- mines;

- working chamber;

- neck;

- hatch covers installed on top.

The material used in the manufacture of the well affects its shape, size and parts of the structure. The type of underground chamber, which depends on underground utilities, is also determined independently.

Tip: these structures and their dimensions must meet the requirements for servicing communications that are suitable for it.

Standard sewer wells have a working chamber height of 1.8 m. The mine is usually round in cross section and has a special ladder for easy descent and ascent.

The instructions for use require that all sewage wells are covered with a special cover for well structures. The need is caused not only by protecting the system from foreign objects, but also for the safety of people.

Calculate the size of the structure

If the diameter of the pipeline does not exceed 300 mm, the placement of a round-shaped structure, the diameter of a sewer well is 1000 mm, while the working chamber should have a diameter of 700 mm will be optimal. When exceeding 300 mm, it is recommended to mount reinforced concrete structures with a bottom O 1m.

Tip: in this situation it is better to prefer the rectangular option, so it will be more convenient to make a hole for the pipeline.

Tip: make sure that when installing the sewer manhole connecting pipes come to them at an angle of no more than 90 ?. It is allowed to change it only for sewage wells with differences.

Remember, when pipes with different diameters are suitable for the construction, they are necessarily connected along pipe slides.

Kinds

It is customary to allocate wells of the following types in construction:

- lookout;

- checkpoint.

- angular;

- rotary well for sewage;

- station;

- control.

The main use of a structure depends on its method of installation and on the tasks assigned to it. Mainly through them oversee the work of the entire sewage system.

In addition, they are used for:

- overcoming the difference in adjacent elements of the sewer system;

- elimination of the difference in elevations of the driving and discharge pipe;

- eliminate blockages;

- collecting precipitation and dirt accumulating in wastewater.

Inspection well

The classification of such structures is as follows:

- Linear, installed on straight sections of the network.

- Rotary, placed at the points where the sewer changes direction.

- Nodal, arranged in the joints of several sewer lines.

- The control one is constructed at the junction point of the yard, intra-block, street or central sewer network.

The easiest way is to build a linear inspection well for sewage, which does not require special skills in its installation. The length is related to the size of the pipe diameter: for pipes O 150 mm - 35 m (minimum), O 2000 mm and more - 250-300 m (maximum).

Rotary, in fact, is similar to a specially equipped point where it is possible to perform maintenance of a well, for example, to carry out cleaning of blockages using a powerful water stream. Such structures should be installed at each turn of the sewer pipe. They give access and allow to serve the inlet and outlet of the drainage pipe.

Drop well

Drop sewer wells should be allocated separately. They are needed to align the levels of supply and discharge pipes, in places where it does not correspond.

They are set to:

- reduce the depth of laying the sewer pipeline, from which the price of all work is reduced;

- protection of the system against sharp fluctuations in the rate of movement of stocks and its sharp increase.

The main types of drop wells:

- with water well in the downstream;

- with a vertical pipe;

- with fencing-water wall;

- multistage;

- fast currents

Materials for sewer wells

Manufacturers offer typical sewer manholes made from the following materials:

- reinforced concrete (made of elements and monolithic);

- polyethylene;

- polyvinyl chloride (polymeric);

- fiberglass.

The shape of the wells can be rectangular and round. Most often used for sewage systems last.

Waterproofing sewers

Although these wells are classified as wet type, it should still be sealed. Waterproofing minimizes the ingress of sewage into the ground.

There are enough ways to seal wells with their own hands. For example, for reinforced concrete structures, special compositions can be purchased in the construction market, which will exclude the contact of dirty sewage with the environment.

Tip: do not forget to read the instructions, which will write step by step all your actions.

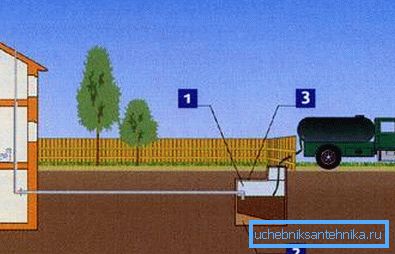

Cleaning the sewer well

Periodically, the dirt in the autonomous sewage pipe clogs, which significantly reduces its effectiveness.

Therefore, from time to time it is necessary to carry out its cleaning.

- Ilosos, Such a special technique makes it possible to clean the well from the accumulated dirt from the drains. In fact, it is an assenizatorskaya machine, equipped with a vacuum pump and a tank. Elososom best to carry out preventive cleaning or pumping from sealed wells. This method today is considered the most effective.

- Hydrodynamic method - release of water into pipes occurs under high pressure. All deposits after such cleansing are collected in one place. The method allows you to cope with any blockages and is considered universal.

- Vacuum pumping happens by means of the powerful vacuum pump. Allows you to clean the sewer and produce pumping drains. The method is considered to be the most environmentally friendly, since wastewater after pumping out is taken to the disposal point. It is recommended to use constantly.

- The method of thermal washing It reminds hydrodynamic, but now the water is supplied heated to a temperature of about 160? С. The method is not popular due to the complex implementation, although it effectively removes fat deposits inside the pipes.

- Strong chemical preparations are used during the chemical washing process.. The method is considered effective and completely harmless, but expensive because of the high price of reagents.

Conclusion

Sewer wells are an integral part of any sewer system. Their types and types help to effectively monitor it and carry out preventive, repair work and cleaning. In the presented video in this article you will find additional information on this topic.