What cable is needed for the well pump

As a rule, the cable for borehole pumps in the factory equipment is not enough to connect to the power source and it has to be increased by an additional piece. Finding exactly the same marking is extremely difficult, so most often you have to use other brands, but here there are some rules that will help you when choosing.

We will talk about some of the features and specifics of electrical wires for such purposes below, and also see the thematic video in this article as an addition.

Choose a cable

Note. In most cases, manufacturers of submersible pumps offer their cables to increase the length, but their price is too high, therefore, most often resort to other options. In such cases, any suitable cable VVG or PVA of the desired cross section is suitable. Although many argue that the TML brand will be the best solution, although in practice, according to the author of this article, there is no difference.

Length of cable

- In order to choose the right cross-section of the cable, you need to know the distance that you are going to lengthen it and the power of the pump being operated. If everything is clear with the power (it is written in the data sheet and on the unit itself), then the length is determined from the automatic machine (power source) to the pump itself (not to the junction).

- Most often, such a parameter as the length is not paid attention, since the additional piece does not exceed two to three dozen meters, but this is not always the case. For submersible pumps, the cable length should not exceed 6% of the maximum allowable voltage drop.

This can be calculated using the formula L = (V *? V) / (I * 2 * 100 * (PF *? / Q)).

- Here L is the maximum allowable length;

- V is the rated voltage (V);

- ?V - voltage loss maximum (%);

- I - the value of the submersible pump (A);

- p - 0? 02ohm / mm3 (resistivity for copper);

- q - cross section (mm) for the cable;

- PF = 1.

Section Selection

As already mentioned, the cable for borehole pumps is selected according to the ratio of the cross section / power, but to make it easier, you can use the table below.

| Engine power | Cable section (mm2) | |||||||

| 41 | 41.5 | 42.5 | 44 | 46 | 410 | 416 | ||

| kw | l with. | Cable length (m) | ||||||

| 0.25 | 0.33 | 70 | 105 | 170 | ||||

| 0.37 | 0.50 | 60 | 90 | 140 | ||||

| 0.55 | 0.75 | 45 | 70 | 110 | 180 | |||

| 0.75 | 1.0 | 35 | 50 | 85 | 140 | 210 | ||

| 1.1 | 1.5 | 25 | 35 | 60 | 95 | 145 | 240 | |

| 1.5 | 2.0 | thirty | 45 | 75 | 115 | 190 | 305 | |

| 2.2 | 3.0 | thirty | 50 | 75 | 125 | 200 |

Table for single-phase (230V, 50Hz) submersible pumps

| Engine power | Cable section (mm2) | |||||||||||

| 41 | 41.5 | 42.5 | 44 | 46 | 410 | 4z16 | 425 | 435 | 450 | 470 | ||

| kw | l with. | Cable length (m) | ||||||||||

| 0.37 | 0.50 | 300 | ||||||||||

| 0.55 | 0.75 | 250 | 380 | |||||||||

| 0.75 | 1.0 | 195 | 295 | |||||||||

| 1.1 | 1.5 | 145 | 215 | 360 | ||||||||

| 1.5 | 2.0 | 105 | 160 | 265 | 425 | |||||||

| 2.2 | 3.0 | 70 | 110 | 160 | 290 | 440 | ||||||

| 3.0 | 4.0 | 55 | 85 | 145 | 220 | 330 | ||||||

| 4.0 | 5.5 | 40 | 60 | 105 | 165 | 250 | 415 | |||||

| 5.5 | 7.5 | 45 | 75 | 120 | 180 | 300 | 480 | |||||

| 7.5 | ten | 35 | 55 | 95 | 135 | 220 | 340 | 585 | ||||

| 9.2 | 12.5 | 47 | 75 | 115 | 190 | 300 | 470 | |||||

| eleven | 15 | 40 | 85 | 95 | 160 | 260 | 405 | |||||

| 13 | 17.5 | 60 | 85 | 140 | 225 | 350 | 490 | |||||

| 15 | 20 | 50 | 75 | 125 | 195 | 305 | 430 | |||||

| 18.5 | 25 | 58 | 100 | 155 | 245 | 340 | 485 | |||||

| 22 | thirty | 49 | 85 | 130 | 205 | 285 | 410 | 570 | ||||

| thirty | 40 | 36 | 63 | 95 | 152 | 210 | 305 | 425 |

Table for three-phase (400V, 50Hz) submersible pumps

It would seem, why pay so much attention to the selection of the cable section, and why do you need instructions here? In fact, this affects the duration of the service life and the work of the unit itself (learn here how to make a filter for a well).

The fact is that when the cross section is lowered, the resistance increases, therefore, the metal (in this case, copper) wires are heated, from which the insulation and the heat-shrinkable sleeve are heated.

Such a process can lead to a short circuit or simply to the drying of the insulation, which makes it unusable. In addition, the energy expended on heating, does not receive the engine, which means that it will not be able to deliver the required power.

When connected, it may turn out that the pump cable for a well consists of three or four cores, but this mainly depends on whether the pump is single-phase or three-phase.

So, for three-phase power supply, you definitely need four cores, while options for one phase are possible - everything will depend on the automation. This automation (pressure switch and dry-running sensor) can be produced as one unit, but can be connected autonomously, although this factor does not affect the number of cores - it happens differently.

Compound

Note. The heat-shrink sleeve is a tube of a certain diameter, which, when heated, is tightened and after cooling it remains in the same position. Such couplings are made from polyolefins (organic substances and synthetic polymers), resulting in a durable and elastic material.

To connect two pieces of the cable with your own hands, first of all, you should pay attention to how to twist the conductors so that they do not burn out and do not explode under tension.

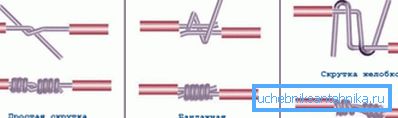

The upper figure shows three types of twists used in such cases, but the first two methods are most often used - simple and bandage. Practice shows that they are strong enough to break and never cause arcing.

Do not forget that before proceeding to the splicing of the cable, it is necessary to put on heat shrinkage - a thick tube on the cable itself, and thin sleeves on each core separately.

After you have done this, carefully cut all the wires to the required length, trim the ends, approximately 50-60 mm and splicing. After that, push the small sleeve on the twist and solder them, and then solder the upper shrink, as shown in the photo above.

Coupling without coupling

In fairness, it should be noted that it is not always necessary to use shrinkable sleeves and twisting to build up the cable on submersible pumps, but this applies only to wells. The fact is that the wellhead is very often made with a terminal block inside, with which it is possible to perform splicing (see also the article Types of wells and their features).

This is done quite easily and simply - the ends of each of the veins are trimmed about 10 mm and inserted into the holes opposite each other. It is very important here, to clamp the bolt with the necessary effort, because by pinching it, you can flatten the wire along the small veins, thus creating a weak section in cross section.

Note! If you do not tighten the bolt tightly, then sparking may occur in the block, which leads to oxidation and sometimes melting of the block.

In most cases, plumbers do not use the terminal block, using a heat shrink sleeve for building. At the same time, the cost increases by a penny, and the reliability of the connection increases significantly.

Conclusion

In conclusion, I would like to say that you do not need special tools, such as a soldering iron or a blowtorch, to heat shrink sleeves on the cable of a submersible pump. The polymer can be heated with open fire, and even ordinary matches and dry chips in the form of a splinter are enough (learn also how to make a drill for the well with your own hands).

Successes!