What can be a downhole filter

For a country house or cottage water supply, it is imperative to install a borehole filter as a precautionary measure against unwanted extraneous elements. It should be noted that such cleaning systems can be fundamentally different from each other in their design, because they, as a rule, are announced for screening and / or neutralization of certain unwanted elements present on the site and aquifer.

That is why for different areas you need to select different filters, which will be discussed below, and you can also watch the thematic video in this article.

Why do we need cleaning devices

Items to be neutralized

- Natural sources of water as a result of human activity on earth have suffered greatly from direct contact with various minerals, and now many of them are rich in iron, manganese and hydrogen sulfide. In addition, pesticides, herbicides, nitrates and various microorganisms harmful to human health are washed away from the upper layers of the soil by atmospheric precipitation.

- After the well has been drilled into the water, the instruction requires prolonged pumping with a submersible pump or airlift, until the composition of the water becomes unchanged. After such manipulations, a laboratory analysis is conducted that determines the presence of certain substances, which will help determine which filter you need.

Note. Never forget that each well has an individual character, depending on many factors. Therefore, even in the adjacent area, chemical analysis of water may differ from your samples, therefore downhole water filters will also differ.

Varieties of cleaning systems

At present, hard water is far from uncommon, but it is impractical and even harmful to eat it or even for technical purposes (for example, washing clothes). Therefore, both in the private sector and in civil engineering and at industrial facilities, install water softeners, which you can install at home with your own hands..

For home, the performance of such systems can vary from 0.2 to 10 or even 20 m3/ hour, whereas for large objects filters are installed with a capacity of 30 m3/ hour and higher.

The principle of operation of such devices is the effect of cation exchangers on ions of iron, magnesium, calcium, and so on, replacing them with hydrogen or sodium ions. Such cation exchangers can be in different forms, but most often it is the Na-form (sodium) and H-form (hydrogen), so the replacement depends entirely on the form of the cation.

For domestic and commercial needs, as a rule, the Na-form is used, but the H-form is used for the removal of salts with special water treatment.

Such systems of water purification in wells are used to remove unpleasant odor and color from water, as well as chlorine impurities and various organic pollutants. Such devices consist of a container with a cartridge, which is very easily replaced with a special key and even a teenager can do it.

The life of the cartridge is about two to three months, but in some cases, with a high content of harmful substances, they have to be changed much more often, as it becomes contaminated.

In order to determine the degree of contamination of the filter, it is not at all necessary to remove the cartridge for visual inspection, as you will feel this when using water. First of all, there will be a noticeable decrease in taste, as well as the appearance of extraneous odors or impurities in it.

In addition, the throughput of the filters is reduced - when recruiting water from a tap, the pressure will be much weaker than usual, and all these signs indicate the need to replace the cartridge.

Perhaps the most common element that needs to be neutralized in water is iron and its content of only 0.3 mlg per liter is harmful to the human body and, in addition, this water leaves yellow (rusty) spots on linen and drains on toilets and devices.

In such situations, devices for complex well cleaning are often used, but in general there are three methods - reagent, reagent-free and complex.

- The first method involves the removal of iron using chemical elements. The reagents themselves are dosed in the right amount before the filter.

- The non-reagent method involves purification using oxygen that is contained in the air. Iron is collected on the filter when loading.

- The complex method is also reagent, only the filter is washed with a solution of sodium chloride, after which it is again ready for use.

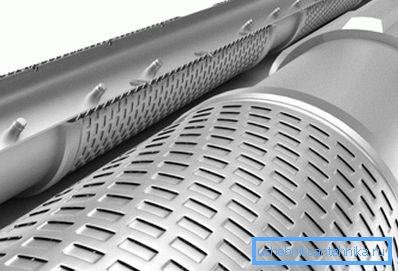

Note. The best for cleaning wells, as a rule, are systems in which there is the following set: pipe for the base, wire frame and mesh for well filters, which is made of stainless steel.

The most effective at the moment are ultraviolet filters that are designed to disinfect wastewater, industrial and natural waters.

Such systems are completely neutralized:

- all controversy

- fungi,

- bacteria,

- viruses,

- and other organic compounds of a harmful nature.

But the smell, color and taste of water does not change. It is important that chlorine is not able to neutralize lamblia, while ultraviolet systems cope with this 100%.

Conclusion

It is noteworthy that for artesian wells (on limestone) filters are most often not used, since there is the possibility of installing a pump far above the filtration layer and all unwanted substances simply settle to the bottom. But for wells on sand, such cleaning is obligatory, and its price will depend entirely on the complexity of the filter itself and its quality.