What is a two-way crane, where and how it is used in

In heating and cooling systems, a two-way valve is often used, which is capable of ensuring prompt and precise adjustment of the volumes of water supplied or withdrawn. The device is also one of the important elements in the ventilation circuit. Today it is widely trying to use a two-way valve for water with an electric drive, which is controlled by various sensors. They are distinguished by ease of installation, reliable operation and ease of maintenance.

In addition, their task is to ensure the specified parameters of the binding unit and other systems where they are installed. Below we will deal with this locking device in more detail.

Features of the equipment

The main difference between the device and other valves is that it is designed to pass water only in one direction. In case of reverse installation, it may work incorrectly or simply fail.

Tip: we recommend installing a filter in front of the valve that can trap solid particles so that they do not damage the valve.

Differences

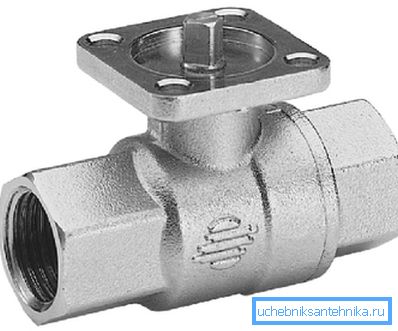

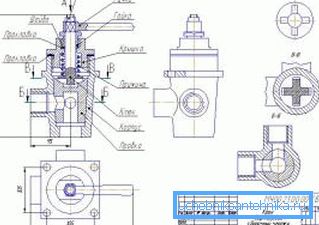

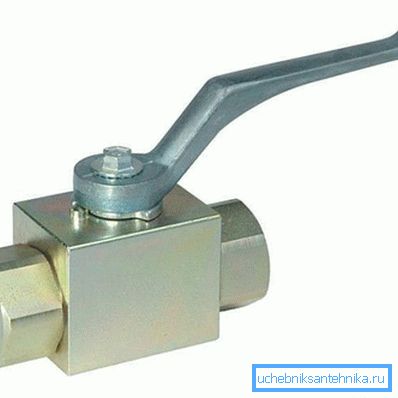

Generally speaking, it has constructive similarities with standard valves and a number of some differences. For example, the locking element of the device can be a ball or a rod of a special design.

In this case, adjustments are made with their own hands by turning the ball that has the hole 90? around the axis or by the movement of the rod in the vertical direction using a lever on top of the device body. Such work can also occur due to electric or pneumatic actuators connected to temperature and pressure sensors.

Design

Depending on the characteristics and purpose of the two-way valve can be made of different materials. Most often this happens:

| Steel, cast iron | The regulating device is used in systems with high consumption of steam or water. |

| Brass | The design has small overall dimensions and is used in ventilation systems of small premises and buildings. |

The crane can also be made in a single and double seat version. In the latter case, the instruction allows, due to the design features, to be adjusted up to shut off flow, in which there is a large pressure drop preventing the operation of single-seated valves.

Tip: you can choose a two-way valve as a separate structure, to which you need to connect a separate actuator, or on it it will already be mounted, most often electric.

The device can be equipped with different types of operation with electric drives, including:

- low power electric motors;

- pull-in solenoids.

A two-way regulating valve can be the main control element of a cooler or air heater, changing the flow of coolant to the heat exchanger. This method of adjustment is the simplest, but it is not free from shortcomings, so it is better to use it in the simplest cases.

Important knowledge

Produce the device many businesses and companies around the world. Each tries to make its own adjustments related to the modernization and ease of use of the crane in production and in living conditions.

Below you will learn what you need to remember and know when choosing a device:

- It is designed to adjust the flow of oil, steam, cold and hot water in steam and heat supply systems.

- They are controlled by electric drive, pneumatic drives, thermostats and pressure differential regulators.

Tip: if you use a valve without an actuator, it can cause leakage through the stem.

- The crane is regulating, therefore a screen filter should be installed in front of it to avoid mechanical damage. The price of the latter is small, but it does a tremendous job. This will keep the equipment for a long time without damage.

- The valve can be single or double. Due to the separation of the flow, the latter design of the device allows the actuator to close it with a strong pressure drop, which cannot be done with a single-seated valve. The disadvantage is a higher leakage with a fully closed valve.

- The material of the body of the crane gives it certain characteristics. Usually use steel, cast iron and brass (the latter is most often found on sale). The maximum pressure for which the valve is designed:

- brass - up to 16 atm .;

- cast iron - up to 25 atm .;

- steel - up to 40 atm.

A two-way valve made of steel can be used at the highest temperature and pressure. Brass is least resistant to these parameters.

Tip: when the working environment temperature is more than 150 ° C or the vapor pressure is more than 4 atm, it is necessary to install cooling elements. They will help preserve the crane and equipment itself, and will also be an additional factor of safety and preservation of life and health of people.

Conclusion

If you need to regulate the flow of water in the heating or cooling system, a two-way valve will help you. It is made of different materials, including steel and brass, while in the first case it is most resistant to pressure and temperature, in the second - the least resistant. (See also the article Filter for heating systems: features.)

Installation of the device is possible only with a mesh filter that traps dirt accumulated in the water supply, heating or ventilation system. The video in this article will provide an opportunity to find additional information on the above topic.