What is airlift for the well, and what are the features of

Airlift for a well is a device designed to lift water to the surface by means of compressed air.

The principle of operation of the device is as follows: a certain amount of air is pumped under pressure into the water intake well and the corresponding volume of water is subsequently pushed to the surface.

Operational features of airlift

Airlift is an alternative to the traditional submersible pump. There are tubular wells, the diameter of which does not contribute to the full operation of pumps of the submersible type. The exit from a difficult situation was an air lift, the main feature of which is the location of the compressor outside the well, since only the pipe is immersed in the water intake well.

The instruction manual device is as follows:

- Air is supplied to a seamless metal pipe immersed in water under high pressure.

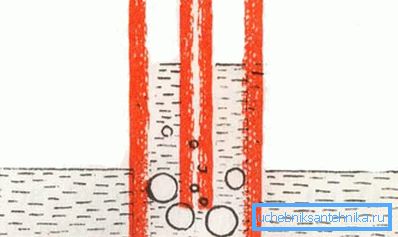

- Air, intensively mixing with water, forms an air emulsion, in essence, a mixture of water and air bubbles.

- The resulting air emulsion rises in accordance with the physical law on the difference in specific mass (in this case, water in the well and the emulsion in the pipe). Since air emulsion is an order of magnitude lighter than water of natural density, it rises above.

The rate at which water flows to the surface depends on the pressure under which air flows into the pipe.

But there is an important point that should be considered when designing and assembling airlift: excessive air pressure can result in a number of undesirable consequences.

- First, high pressure during operation of the device is potentially dangerous for both the well filter and the walls of the well.

- Secondly, during the operation of the airlift from the bottom of the well under high pressure will rise not only water but also the rock interspersed with mud. As a result, the installation will not be able to provide clean water.

- Thirdly, the injection of air under high pressure turns into significant energy consumption, which makes the operation of the device in continuous mode unprofitable.

Construction features

Airlift features a simple design, and therefore the device can be made by hand. There are no moving parts in the device, as the blower is located outside the well. Therefore, airlift resistant to abrasive loads of sand.

Used airlifts according to the principle of action are of two types, namely, injection (most of them) and suction.

- If an injection type installation is used, the pipe is lowered into the well below the water level. On the surface of the pipe is connected to the compressor, which produces compressed air. For normal operation of the installation, the pressure should not exceed 15 atmospheres. The emulsion resulting from the mixing of water and air will rise in the storage tank. After some time, the air from the solution will come out and water will remain.

- During operation of the suction airlift, the pipe used is lowered slightly below the water level in the suction well. During the operation of the compressor, in the lower part of the pipe air is mixed with a certain volume of water. As a result, the resulting emulsion due to the difference in weight with ordinary water rises to the surface.

Important: Regardless of the type of equipment, stainless steel seamless pressure pipe is required for full operation. The use of plastic pipes or hoses is impractical because of the high probability of rupture.

The intensity of the water supply determines not only the diameter of the pipes for the airlift of the well, but also the tightness of the connections. If all piping connections are sealed, water will rise to the surface in accordance with pre-calculated calculations. If the tightness is insufficient, the intensity of water intake will be an order of magnitude lower than the original calculations.

Alternative use of airlift

The use of air lift systems is important not only for water intake. Sooner or later, the wells are clogged and silted. In this case, the well will need to be purged using an airlift.

Of course, in order to neutralize the blockage or to clean the water intake well from sludge, the compressor power is required an order of magnitude greater than that provided by the devices used for lifting water.

A jet of compressed air with a force pulled out of a hose and destroys an obstacle in the form of blockage or sludge. Further, the pollution, under the action of the pressure of the injected air, is carried to the surface through the service pipe, where they can be collected and disposed of.

The advantages of this method of well blowing are obvious and, above all, it is:

- The possibility of high-quality cleaning of water wells;

- Availability of equipment, as the compressor of the required performance can be rented or bought;

- The possibility of exploitation of their own hands, as the process of purging is simple and if necessary can be carried out independently.

Does this method have disadvantages?

Unfortunately, the use of a powerful airlift creates a danger, both for the well itself and for the equipment it uses.

- Danger of breaking through the fine mesh applied in the filter design. Of course, filter manufacturers, developing modifications used in airlifts, take into account the pressure parameters and make maximum efforts in order to make the life of this part as long as possible. But a long filter life, the price of which is high, is possible only with a short-term supply of compressed air.

Important: The impact of air on the surface of the filter adversely affects the state of metal parts, which, due to microdeformations, are more susceptible to corrosion.

- Uncontrolled release of silt and sand from the well. When flushing, the well turns into a source of dirt, which spreads a few meters around. Thus, before applying airlift, you need to take care that the space around the intake well is something securely covered, for example with a plastic wrap.

- The possibility of purging in shallow wells (usually not deeper than 40 meters).

Conclusion

Independent application of airlift is not particularly difficult. The main thing is to choose the capacity of the compressor in accordance with the parameters of the well and the immersion pipe. More useful and interesting information can be found by watching the video in this article.