What is the best pump for the well: an overview

Any country house that does not have a direct connection to the central water supply system should have its own water source, otherwise it will be extremely uncomfortable to live in such a house. The same applies to summer cottages, which need a watering system for the normal growth of vegetables, flowers and fruit trees.

To provide the site with a continuous supply of water in the right quantity, you can use two options:

- installation of supply tank of large volume;

- drilling your own well.

As practice shows, it is much more profitable to drill a well than constantly ordering imported water to fill the feed tank. That is why the owners of private sites usually equip their own source and install a unit for supplying water to consumers.

In order to understand which well pump is better for your needs, it is necessary to study their types, main technical indicators, advantages and disadvantages.

Types of borehole pumps

Units for extracting water from a finished well, according to the type of location can be divided into:

- deep;

- superficial.

Surface units are installed outside the well and are used mainly for shallow mines up to 10 meters.

It is not economically profitable to use such pumps at a greater depth, since more powerful electric motors are required, which in turn consume an unjustifiably large amount of energy. It must be ensured that the unit is not idling (without water), as this will damage the motor.

Pump selection

Depth aggregate is the best pump for the well, since it is designed for full or partial immersion in the aquatic environment. This type of unit is used for mines with a depth of more than 10 meters.

It is important to pay attention to the case material, since the unit works in water, it is desirable that the case be made of stainless steel. The price of such a device depends on the case material and the availability of control automation.

Types of submersible pumps

Depth apparatuses for wells are widely used and by the method of supplying water to the surface are divided into two types:

- centrifugal;

- vibrating.

Vibration units are used in sand mines at a depth of no more than 45 meters. Such devices are relatively inexpensive and very simple in the device. Inside the case there is a metal core, a rubber membrane and two valves (suction and delivery).

When a current flows, the core draws water into the pump casing through the inlet valve with a membrane, and after turning off the current, squeezes it through the discharge valve to the surface.

Such a device is not afraid of falling into the working cavity of large fractions of sand. However, despite the low cost, the service life of such a unit is much lower than that of a centrifugal one.

Tip! The best borehole pumps are centrifugal. This type of units can be used not only for the transport of water, but also for chemical liquids. Despite their small size, the pumps have high power and are capable of raising the water column to a height of 300 meters with a small expenditure of electricity.

The pump has an electric motor in its housing, on the shaft of which the blades are located. The engine generates high torque, and the water is pushed through the discharge non-return valve with the help of blades and under the influence of centrifugal force.

Such units are available in different sizes (from 50 cm to 2.5 meters) and with different diameters (from 10 to 50 cm). You can install such a unit yourself, without the help of experts.

Important criteria when choosing

- In order to choose the right pump for your well, it is necessary when choosing a unit to take into account such criteria as:

- diameter of the body relative to the diameter of the well;

- cost;

- height of water column;

- performance;

- water quality in the well;

- plant manufacturer.

- The diameter of the well, for obvious reasons, must be greater than the outer diameter of the pump casing. Each well is accompanied by instructions from the drilling company, in which you can find out these figures or measure them yourself.

It is desirable to immediately convert the received dimensions in centimeters to inches, taking into account that one inch is 2.54 cm, since on most domestic and all foreign units, the manufacturer indicates the diameter in inches.

- When buying a pump, the cost item must include:

- steel cable for mounting the unit in the well;

- electrical cable of the desired length;

- automatic machine for connecting the unit to the mains.

- Of course, expensive models usually turn out to be much better than cheap ones, but this does not mean that you need to buy an expensive unit. If you use the well extremely rarely, and in the winter, preserve it altogether, it is possible in an expensive unit and there is no need. If your well supplies a private house where you live permanently, then of course it is better to purchase a more expensive model.

- An important indicator is the height of the water column and performance. When choosing a pump for your well, one should take into account the depth of the mine in meters and add another 20% to this indicator to ensure normal pressure in the domestic water system or water supply system.

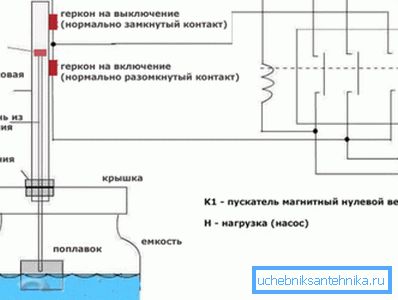

- In private residential houses, a special additional unit is usually installed with a supply capacity. Water from the well is fed into the supply tank, and already from it, with the help of an additional centrifugal pump, is fed into the water supply system under pressure.

- It is also worth considering the water quality in the well itself and the presence of fine sand fractions in it. In low-cost models of centrifugal units, the injection blades and valves usually wear out quickly when pumping such a liquid, so for such models you need (if possible) to purchase an additional filter.

In the more expensive models of foreign production, special separation systems are provided for cutting off and removing heavy sand fractions, therefore, the price of such a pump grows significantly.

Features of the installation of a submersible pump

When installing a submersible pump, it is important to follow a few basic rules:

- make pumping and cleaning of the mine before installation;

- securely attach the hose for lifting fluid and a metal cable (photo);

- connect the power cable using a waterproofing cable box;

- check the unit for operability by short connection to the network.

The lowering of the unit into the well is done smoothly, using a metal cable. Every 2-3 meters it is necessary to fix the power cable and the hose to the cable with clamps.

Some units do not have a non-return valve that prevents water from flowing back into the well when the unit is stopped. In such cases, you must buy the valve separately and install it.

Conclusion

Which pumps are best for a well in each particular case are usually determined by competent specialists, based on the data specified in the well instructions (see also Filter for a well - features of choice).

In most cases, when ordering to drill the source, the crew immediately after the execution of work indicates all the parameters and give recommendations on the arrangement of uninterrupted water supply. Well, there were still questions left - see the video in this article.