What to cover up the seams in the well: an overview of the

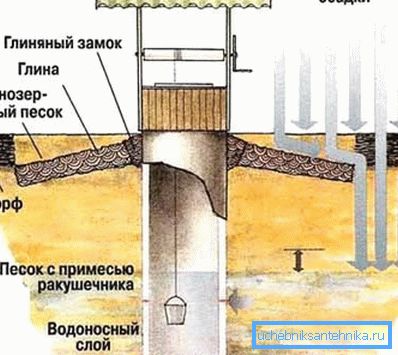

In order to organize uninterrupted water supply of a country site, in most cases it is impossible to do without a well. Such sources are built from wood, stone, brick or concrete. But whatever material for their creation was chosen, no matter how well the construction was constructed, any well will sooner or later require repair.

For example, in concrete sources, rings often shift, in stone wells, cracks and gaps between the masonry are formed, and wooden structures are highly susceptible to rotting.

All this leads to a violation of the integrity of the walls, and as a result - to the deterioration of water quality due to the penetration of the upper polluted water into the reservoir along with the soil. Moreover, due to heavy precipitation and snow melting, this process is intensified in spring.

Consequently, the problem of how to seal the seams in the well, worries almost all owners of suburban areas, which is located on some type of tank. Any unambiguous instruction to resolve this issue is missing, since the sealing of the seams of the well can be made with various materials. Moreover, the order of such works in each type of construction is different.

Therefore, due to the presence of more than one nuance, with regards to the question, the better to seal the seams in the well, before starting work, you must first examine all the details in more detail. So, with the help of what and how should waterproofing of the seams of the well in each specific case occur?

Note! It is not recommended to postpone waterproofing works in any case, since water in violation of the integrity of the walls of the well not only becomes unfit for consumption, but can also cause serious diseases. In addition, its pollution will lead to breakage of the pump and filters installed in the tank, and the price of such equipment, as is well known, is far from being democratic.

Popular materials used to seal wells

Now there are many materials for sealing the seams in the well. Each of them has a different degree of efficiency and features, so let's look at the most popular options in more detail. (See also How to choose a pump for a well: selection parameters.)

So, the sealing of seams in the well is carried out mainly with the following list of materials:

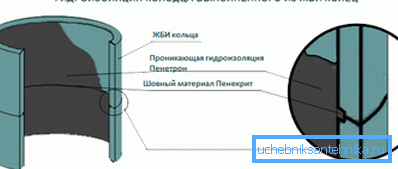

- Ready dry mixes. These new generation materials are created on the basis of cement with the addition of chemically active additives, due to which they acquire improved waterproof properties. Also, their advantage is that such mixtures are able to adhere well to concrete surfaces, so this option is preferable for sealing wells made of this material. For example, high-tech mixtures "Penetron" or "Waterplug", well-proven in waterproofing works, allow you to create an almost monolithic surface, which is not susceptible to destruction for many years. Ready dry mixes are sold in specialized stores.

- Bitumen-gasoline solution. Such a mixture can be prepared with your own hands from gasoline and bitumen, the brand of which should be chosen no lower than 3. 3. The sealing of the well joints with this material should be carried out in 3 layers, the first of which will be a primer. For the first application of the primer, the solution is prepared in a ratio of 1 to 3, and for subsequent layers - 1 to 1. The application of this mixture is carried out using special equipment that supplies liquid building materials under high pressure, for example, cement cannon. This solution is flammable, so sealing the seams in the well with it should be carried out with careful observance of fire safety standards.

- A mixture of cement (not below grade 400) and PVA. Sealing of well joints using this thick mortar is done by plastering using a conventional spatula. Often, to enhance the sealing effect, liquid glass is applied over the cement and PVA mixture.

- Warming tapes (rubber, jute or linen, impregnated with fibrous rubber). These building materials are used in those cases when there are no other means at hand to eliminate the well leak. Such a process takes place using the caulker method. A caulk with such tapes allows to close up the seams of the well if they do not exceed 7 mm. However, it should be noted that this is not the most reliable way with which you can achieve excellent results for a long time. Therefore, when the question arises, the better to seal the seams in the well, it is first desirable to pay attention to other materials.

Note! In no case for the sealing of well joints can not use toxic materials. These include epoxy resin, which some people use unknowingly for such purposes.

Features of sealing concrete wells

Probably, many have come across or know that over time, concrete rings in the well, if the construction is built with their use, can shift. As a result, in such a source it will be necessary to carry out repair and waterproofing works, otherwise it will no longer be possible to use water from it.

Also, the cause of a concrete well leak can be significant and minor cracks, which often appear in the rings due to the use of poor-quality cement in their manufacture or because of the displacement of the soil during the spring thawing of snow. In these cases, the site owner is also likely to face the problem of how to seal the seams between the rings in the well.

Seal significant and minor damage

As for minor damages in concrete, they can be sealed on one side of the structure with a special waterproof mixture that can be purchased at a store designed for such products. Before applying waterproofing, you should first clear all the weak points of the seams.

Note! In order not to miss significant damage, a small crack should be slightly widened, since at first glance it may seem that way, but often internal rings are found in the rings, which are immediately difficult to notice.

If there is a significant crack in the well, then after stripping the damaged surface, it must first be repaired from the outside of the structure, and then from the inside. It is recommended that an additional waterproofing composition be applied outside the structure. This will prevent the erosion of the seams. (See also the article How to draw water from a well to a house with your own hands.)

In order to get to the defective area, a ditch should be dug around the well to the depth where the problem area is located. After the work, it needs to fall asleep again and tamp.

The process of sealing seams in the displacement of concrete rings

When offset rings waterproofing work will require more time and physical costs.

At the same time, in order to seal the seams between the rings of the well was made qualitatively, the following sequence should be observed when carrying out such work:

- At the first stage, you should first dig out the damaged area.

- Further rings completely understand.

- After that, the displaced rings are set back in their former place, but already in the correct position.

- Then, it is advisable to install brackets in the place of all the joints of the rings, thereby fixing the barrel more reliably.

- Next, you will need to seal all the seams with a special solution, and then, on the outside of the trunk, additionally apply a waterproofing compound.

- At the last stage, the blind area should be re-made.

Features of sealing brick wells

If there was a question, what to gloss over the seams in the well, which is made of brick, then the sealing of the structure in this case mainly consists in replacing the displaced or dropped blocks, as well as plastering the damaged area.

The order of work in this case is as follows:

- At the first stage, the damaged area is cleaned with a steel brush, and the elements of weak masonry are removed.

- Next, you need to clean the seams of the old cement mortar.

- After that, you need to make a laying of new bricks.

- At the last stage, you will need to plaster the surface where the new masonry was made.

Features of the sealing of wooden wells

How and how to miss the seams in the well, if it is made of wood? As mentioned above, the wooden structures of wells can be rotten in some places, therefore, first of all, it will be necessary to determine in which particular area this happened, and then restore the airtightness, replacing the damaged material with a new one.

To do this, you need to build a working platform with thick boards. Its size should be such that one person who will carry out repair work can easily fit on it.

In order for the ground to move freely up and down inside the well, it should be secured with cables to the beam, which is placed on the headboard so that it can be conveniently lifted with your own hands or with the help of a gate.

In this case, the waterproofing of the seams in the well should occur in the following sequence:

- First you need to suspend the part of the log, located above the damaged area. To do this, "goats" are installed on both sides of the top of the tank. After that on them from all sides of the structure should be placed 4 logs, which in turn will need to nail 2 sturdy boards. Then on them and the crown is fixed with the help of long nails. This will prevent the collapse of the structure during the excavation of rotten boards.

- Next is the removal of directly damaged areas on the wooden house.

- After that, you can already begin to install new logs. At the same time, it is not necessary to immediately discard old material, since it is convenient to use it as a template for the manufacture of blanks. New boards are installed by jamming with a wooden hammer.

Conclusion

Finally, you should focus on the fact that all repair and waterproofing work should be started only after pumping water from the well, that is, after draining it. If you still do not understand how to seal the seams in the well, watch the video in this article. It will surely help you to sort out this difficult question in more detail.